I am trying to use an Ikier36 Watts Laser and incorporate the Automatic Focus entry, and the laser seems to run exactly as it should, and the Laserhead will rise to the top and touch twice and move to the bottom and touch twice. A problem is presented, and this Laserhead will again move, but too high to cut or engrave the wood. This laser has been set to the 5mm gauge often and now it goes there by itself.

The focus used to go to a different location than it does now? I have the 20W version and mine has always gone up to create an 8mm gap between nozzle and material. I have never been able to figure out how to change this, but I would like to because 8mm isn’t a proper focus for engraving. It works good for cutting 2-3mm plywood, but I use layer offsets for cutting at various thicknesses.

I think part of my issue is and was I have the device settings at mm per inch. And all my drawing in Lightburn has set up in inches. I am not sure of this yet. But am going to set everything to mm and try again. I am not sure I understand the off set part. But I have seen it action and it works well. I just do not understand how to set it. I really want to learn this if I can. I have the 36 Watt laser and it should handle what I am cutting and engraving with ease.

I have a hard time believing that’s the problem, but I’m often wrong

I do almost everything in metric, so I’ve never tried the scenario you describe.

Your initial problem description made it sound to me like something in the machine behavior changed. Do I read that correctly?

Is the focus block Ikier sent you 5mm thick? Mine is 8mm. The only 5mm reference on my machine docs are for the clearance recommended between the Z carriage and Z frame at lowest position. I mostly ignore that. As long as the carriage doesn’t bottom out or bind up before the focus switch trips, it works fine.

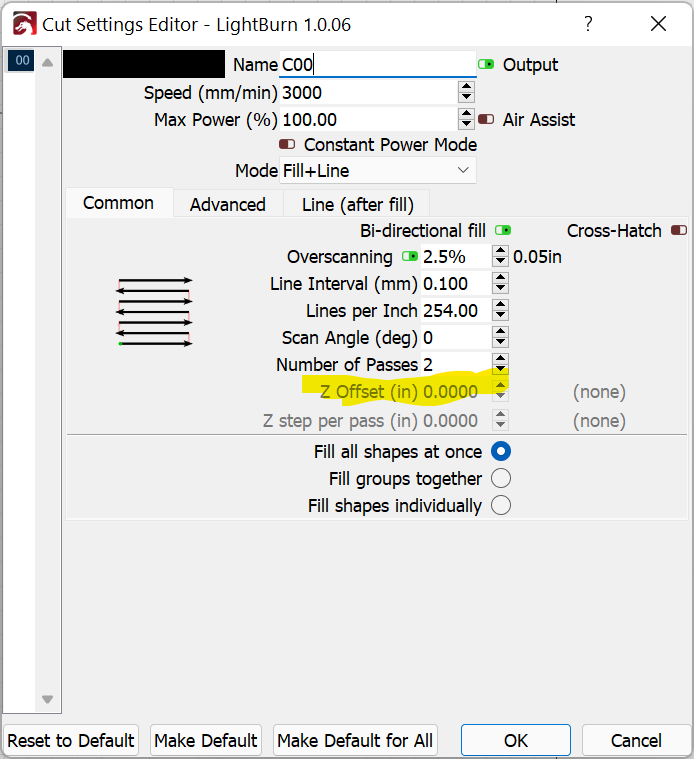

Z offset will quickly become your best friend once you get used to having it. It’s just a positive or negative Z move applied to each layer. I have a particular job where I run a detailed engrave at offset a, defocus to offset b for a wider line to engrave a few thick lines without needing fill (just a time saver. Could do it during the image engrave, but it adds a lot of wasted time & motion.), then move to offset c for a thru-cut.

First, let me say Thank You for answering and helping me, and I appreciate it greatly.

When I first tried the Auto Focus, worked great, and all was good. I ran a little circle pattern at 100 % heat. I am not sure of the speed, but it was high I thought. The laser was up between 6mm to 8mm. All of the settings were in mm. The cut was smooth and clean and there was no edge discoloration.

I then used the pattern I had made with Lighburn. The settings were in inches. I remeasured the laser to the work table again at 5mm per direction and checked to see if I was using the right Laser, and that was correct. I hit the automatic focus button, and the Laser rose to the top, bounced twice, and went to the bottom and bounced twice and then the problem arose, the laser started to rise and did not stop until it was two-thirds of the way to the top and thought this was odd, but not knowing any difference, I hit the start button and it started and was only burning the hell out of the wood. I stopped the machine, came to the start position, raised the heat, went the same speed, and hit the A F and it reacted the same way as before. I did not know any better and hit the start button again with the same results. I have tried several times since with the same results.

I mentioned the laser has always had the device set to mm and the patterns in inches, and I have not tried to have both patterns and settings in mm but will plan to give it a try.

Thanks,

Frank

I have a hard time believing that’s the problem, but I’m often wrong

I do almost everything in metric, so I’ve never tried the scenario you describe.

Your initial problem description made it sound to me like something in the machine behavior changed. Do I read that correctly?

Is the focus block Ikier sent you 5mm thick? Mine is 8mm. The only 5mm reference on my machine docs are for the clearance recommended between the Z carriage and Z frame at lowest position. I mostly ignore that. As long as the carriage doesn’t bottom out or bind up before the focus switch trips, it works fine.

When you home the machine, does the laser go all the way up and stay there?

Did you create the autofocus macro in LB?

After homing do you ever move any part of the machine by hand? (Including the focus knob.)

I can’t see how the focus height would arbitrarily change without a settings change of some type that’s unknown to me or a firmware change of some type that’s also unknown to me.

Question 1: yes it does go up and stay there

Question 2: Yes I believe everything has been done in LB

Question 3: I never move the laser or turn the knob at all by hand. I move the laser to the start spot to start the laser to work.

Can you explain to me how to use the offset you mentioned, please?

Thanks again, I do appreciate the help. As you can tell I am new

;

Mine does the same. IKIER…Bahhh. When you notice the focus may be a bit too high, simply hit the macro again and it should now be right. Check with calipers or focusing gauge. I sometimes have to hit it 3 times. Also…jog the laser through the move tab in Lightburn. It’s not a good idea to move by hand unless REALLY slowly.

“I will definitely try your suggestions. Thank you for your help. If you ever need my assistance, my email is always open to you.

When the laser finds the accurate height, could you please tell me the distance for 3 or 4 mm wood?

Thanks again for your kind assistance.

Best regards,

Frank”

Chris, I have tried to use the offset feature in Lightburn, but when using this feature, it adds so much time to the overall project I have stopped using it. Can you explain to me what is happening when using this feature of Lightburn?

Thanks,

Frank

Do you have “optimize Z” and “relative Z” enabled?

It should only add maybe 5 seconds per offset change. Maybe. Probably closer to 2 if the changes are only a couple mm at a time. Unless you’ve got dozens of different Z offsets, it shouldn’t affect job length in any significant way. The most I’ve used in a single job was maybe 4 Z offsets, so they added at MOST 20 seconds to the job. My average job is probably 3 hours, so the added time is literally insignificant. Each offset change has a specific purpose, so even if they added several minutes, I’d keep using them.

Maybe I am not using the same feature you are referring to. When I am speaking of the offset I am using the feature located below the ruler on the left side on the screen. It looks like race track.