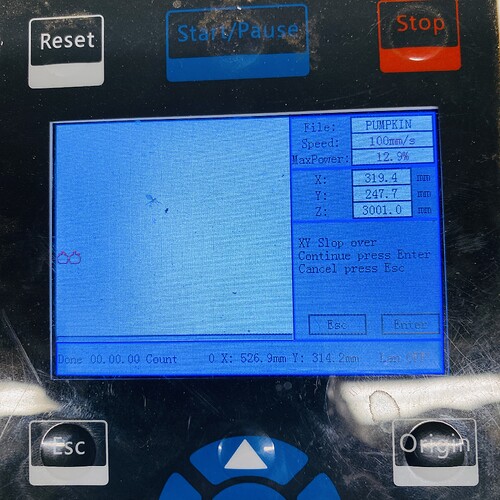

I am using omtech 2440 100watt co2 laser with updated lightburn hardware 1.06.3 I keep getting “Frame Slop Work paused continue press Enter Cancel Press Esc” I can press enter and it works fine but its so frustrating. it is small tiny letters that I am cutting out and it is no where near out of bounds of the my work space. I am using current position for the origin and I just mover the laser to where I want to start cutting and I get this error …my material is is the dead center of my work space. I checked the bed size in my setting and it is correct what else am I missinging? I’ve looked through several topics here but none of them have helped me.

You are moving it with the arrow keys, not by hand, correct?

lol yes I guess you really do have to asked this kind of questions on here lol. I never manually move my laser head.

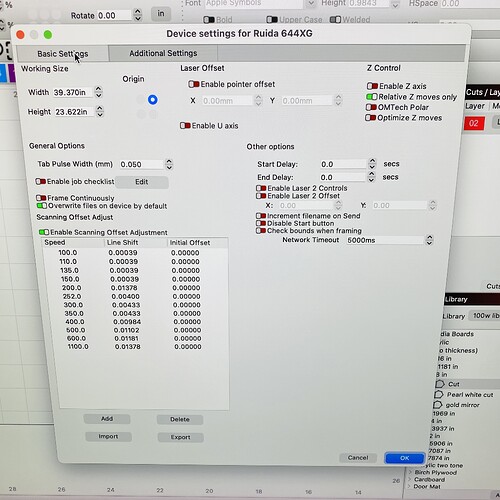

From what I’ve read, it appears to be a Ruida controller, not what your profile states. Might want to fix your profile and you won’t get erroneous posts that do not apply to your machine.

I will assume your machine and Lightburn are configured correctly…

Always make use of the preview with show transversal moves enabled. The red color lines are where you head is traveling. It’s lower cost and much more easy to use the preview, eliminating waste and time … it is not used enough or there would be less posting of issues.

The object is the same size in both of these previews, 50x100mm. The left object is scanned at 1000mm/s the same object, to the right, at 500mm/s.

The red area or lines is the heads movement and includes an overscan area required for the specified speed…

In the left image, you can see a faint green box, this is the defined work area and the red line is going out of the work area. This will cause the Ruida to generate a slop error.

If it’s a Ruida, these error messages are on the console.

Try setting it to absolute coordinates, it should laser where it is on your workspace.

You can move the head to the center area and pressing origin on the Ruida console and set start from to user origin.

This is usually related to speed (actually overscan)… how fast are you attempting to do this.

Don’t ignore these machine warnings… one day it will bite you big time. Never use enter to continue. The dsp, from your upload, that information has determined it will go out of bounds… so far you’ve been lucky. It knows what you are telling it to do and gives a warning only when it isn’t correct for it’s configuration and you could damage the machine.

If the controller complains, you need to adhere to it’s warnings and figure out what’s wrong with the configuration before telling it to ignore the error. There should be no errors/warnings on the controller.

Can you post the .lbrn2 file so we can examine it?

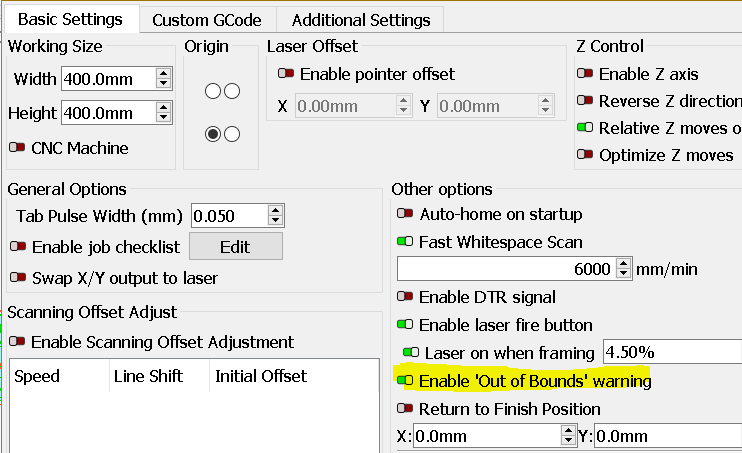

Might want to adjust your lps, so there is absolutely no possibility of exceeding your tubes current limit. ![]()

![]()

That is what is is showing. I just went back to absolute coordinates which such a pain because I can’t figure this out

How do I share that file with you?

If it’s a .lbrn file, then you can just drag and drop it on the reply window. You are also limited to 4mB file size and certain extensions.

Can you show us your start from and job origin settings in the laser window?

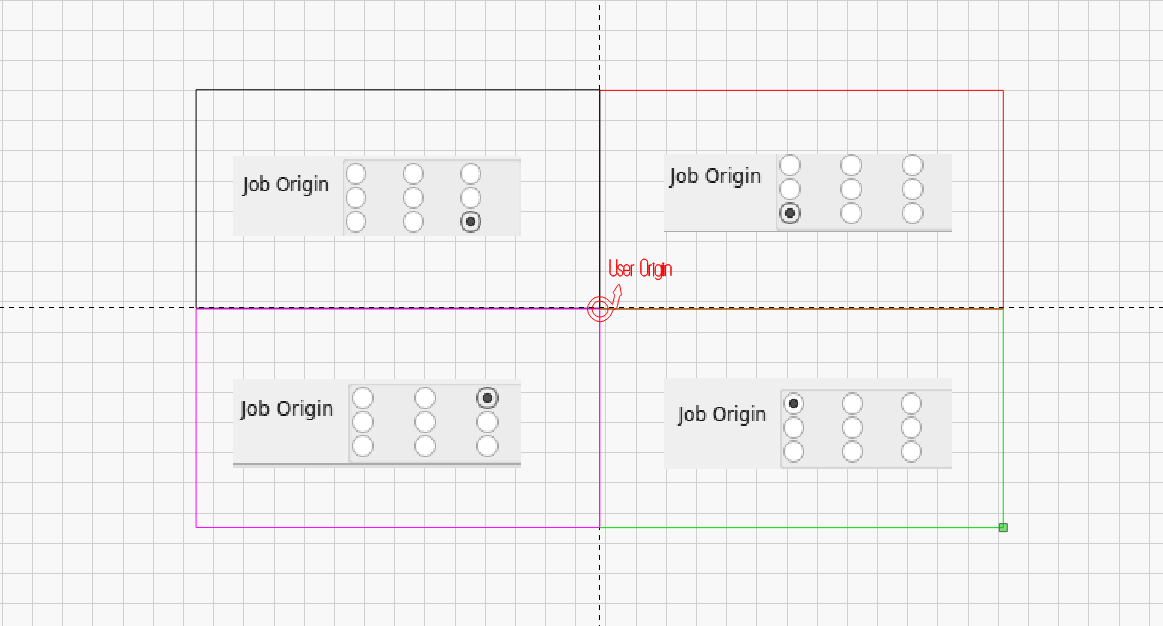

I have user origin set at 0, 0, but it’s relative to this setting, it doesn’t matter if it’s user origin or current position both will work relative to either the set user origin or current position. This option is grayed out in absolute coordinate mode.

It’s pretty clear you are not understanding how this is working… once you get a handle on this, it will be duck soup for you to use any of the modes.

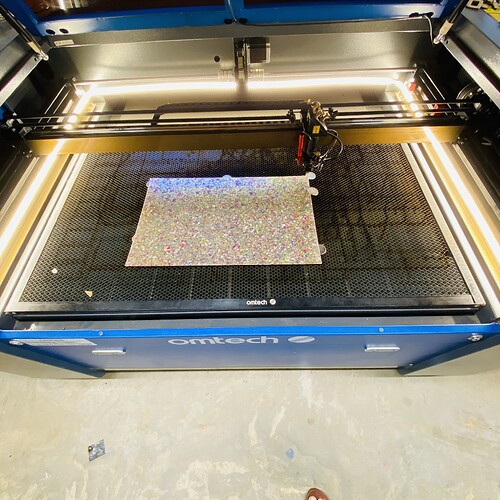

Depending on how this is set… lets use your photo of the material and head location.

In your case, assuming the entire piece is to be engraved, if the job origin selection is on the left selection, the engraving will be to the right of the user origin… if it’s top left, then the graphic will engrave down and to the right… if bottom left up and to the right.

In your case the only applicable selection would be upper right… if you have it set to anything else you will get a slop error.

Does any of the make sense?

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.