That is correct. No matter what we change in the control panel or in LB the actual run/traverse speed is around that 10mm/s.

Curious. I don’t see anything obvious that would be limiting speed to the degree that you’re describing. I’m wondering if perhaps the laser is just never getting up to speed.

Can you upload the .lbrn file that you’re using to test the speed?

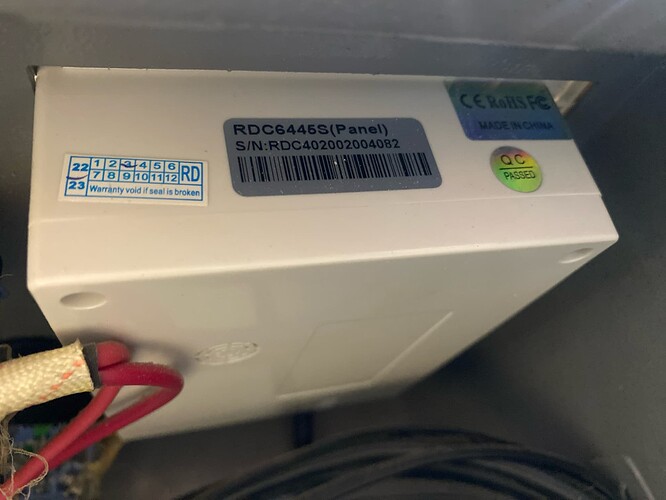

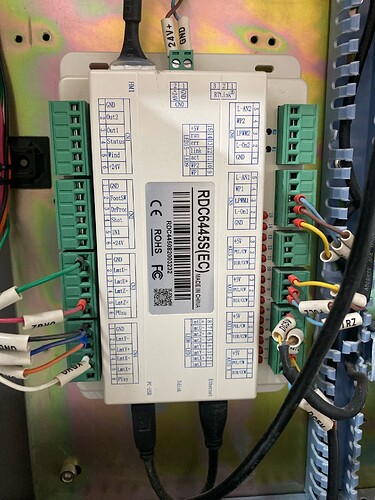

Did you change out only the controller?

Did you get the vendor data from somewhere to populate the new Ruida?

![]()

So we can get the laser moving real quick when jogging around or when is first powered up. We also had it moving great for cutting but never for rastor(fill).

RRS_Logo_LB.lbrn2 (255.5 KB)

Can you elaborate on this? Are you saying speed deteriorates over time? Or are you saying homing speed is fast?

The speed settings in the .lbrn file are absurdly high at 11,000 mm/s. Is that intentional?

What happens if you lower this to more reasonable values? Like 500 mm/s? Check to see if speed changes between 10 mm/s to 500 mm/s. What is the measured speed when set to 10 mm/s?

You are correct about the speed. However it will be limited by the controllers maximum speed … that is 500mm/s that we see in the machines settings.

15,000mm/s would be about 15 times faster than your lps can respond.

What does that tell @CaseCraft about high speeds?

I’d suggest you drop the speed down to ~100mm/s range until you get the bugs worked out and it’s operational…

Running at 500mm/s is not a reasonable way to debug a problem. Much too fast for you to observe anomalies.

@berainlb fyi…

I’ve fiddled with the maximum speeds a bit. It’s around 3000mm/s. If you attempt to write a higher value, it sets the maximum speed to it’s default value of 500mm/s.

This may be a problem for them as it appears that’s the default, not anything related to how well it will perform.

A while back I was wondering what would happen, controller wise, for a valid configuration and a request to do it… I figured it would choke with a slop error.…

I did choke, the error was not enough extended space

Based on the idea that it wouldn’t have enough room for overscan… Seems like it did that, but a different error on the console than I expected.

If you do this on the Ruida, I remember that the Machine settings returned a successful write to the Ruida. Although part of the data to write, maximum speed didn’t, with no error reporting … UDP or just tough ![]() ?

?

I had to re-read the controller to ensure it was updated…

I’m not up to breaking out wireshark to watch this interface…

![]()

So we’ve tried 00mm/s and ramped up to 15,000mm/s with literally zero speed change from actual ~10mm/s(Rastor Only). Running the same test of cutting only showed an increased actual travers speed. So Rasto appears to be stuck at the one speed and Cutting has some kind of %ratio that we’re unable to locate and correct.

Can you go to Edit->Machine Settings and save the settings to a file and then upload here? That will make it easier to do a comparison. Perhaps something we’re overlooking.

Light_Burn_Forum_Mach_Sett.lbset (14.3 KB)

Let me know if this helps.

There is one thing that sticks out vs my settings.

This is what you are showing:

"Desc": "Engraving Mode",

"ID": "0x100400",

"Value": "Special Mode"

This is what I show:

"Desc": "Engraving Mode",

"ID": "0x100400",

"Value": "Common Mode"

That might be worth trying to change although I’m not familiar with what this does.

I’ll upload my factory settings here as a reference in case you want to review more.

OMTech 80W 700x500 Factory Settings.lbset (12.6 KB)

Ruida manual states

Scan mode: There are two modes for your selection: the general mode and the special mode, in the general mode, there’s no any treatment during the scan, in the special mode, light spots will be treated. If the special mode is activated, the power of the laser should be increased and correspondingly, the light spot percentage will be lower and the laser power attenuation will be higher, to achieve the same depth of scanning, the laser power should be higher. The purpose to select the special mode is to make the laser to emit beams at high power and in short period, during deep scanning, the effect of flat bottom can be achieved, however, if the light spots are improperly adjusted, this effect may not be achieved and the working mode of high power and short period may influence the service life of the laser. The default mode is the general mode.

I have to read it that special mode is rough on the tube?

![]()

I read this as well but wasn’t sure if this mapped to the LightBurn setting. it didn’t sound like this would affect speed but thought worth a try as it’s possibly a constant speed, variable power solution but uncertain.

I’ll try this and get back

Made the change to CommonMode , Wrote it to the machine and no change.

Also compared your settings and adjusted all that don’t change the size of the machine and it somehow became even slower. I tried running at 500mm/s and it was almost not moving. lol. I then uploaded my setting back in.

**I truly appreciate everyone’s help here.

There are a number of configurations that wouldn’t be appropriate for your machine. Specifically step size shouldn’t have been changed if that was already calibrated.

This implies that something did in fact cause a change. You should try applying changes one at a time to see which one is affecting the speed.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.