Tan are at the same location when I position my workpiece on different positions on my board

Is this only happening on this design or does it happen with other designs?

Try creating a new project. Create a circle and assign that circle to a different layer than what you’ve used in this project. Does that burn work?

I happened on all three I drew.

Can you try burning this from LaserGRBL? I’m curious what the result would be.

I have the same problem with certain things

You find any solution?

Im not sure what you mean by burning it from Laser GRBL? Ill give it a try if you could push me the right direction

This appears to me to be a power/speed issue. When coming to the ends of arcs your laser may be reducing the power to prevent overburn. You can adjust the Max/Min power in LightBurn to prevent this, or just run the job a little slower.

One of the big problems with wood as a material is that it isn’t homogeneous, you’ll get hard spots that take more power to cut in certain areas - and if you’re running right on the edge of cutting through the material, these can leave hangups like this.

LaserGRBL is a separate laser control program.

This is not a problem of not burning through. There is not even a mark on those spots. I had 2 images on one level on plywood with the exact same misses

Same issue with me. Seems every time I use boolean and or weld images together I have this issue. The last one I started from scratch and created had multiple tiny tabs but then 2 almost 1/4 inch spaces where there was no burn at all, as if the laser lost power. Let me ask, are you using a Mac or Windows base computer. Mac for me.

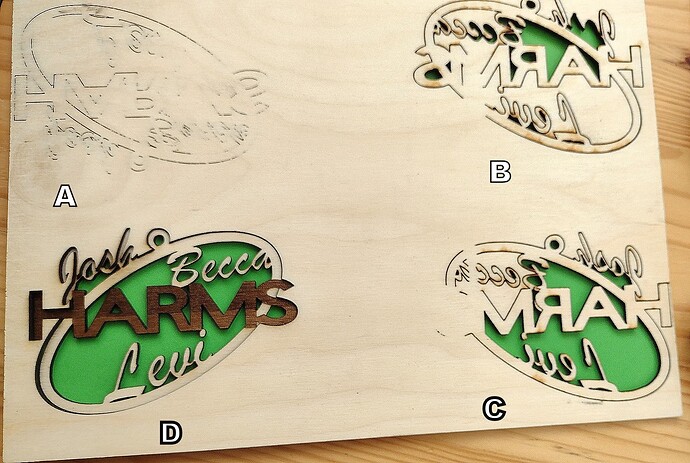

OK so I don’t know the amswer to your problem, but the following may just help. I was impressed with the art work you have done and just had to see if I could produce this file on my machine. I use an Atomstack 40w diode laser. I downloaded the file and imported it into Lightburn. Adjusted the speed and power to my normal settings for 3mm ply and started the process. I’m agreat beliver in If you first don’t succeed Try, Try and Try again. You will see from the images here that it took 4 attempts to get to almost succees. Note for attempts A was too low on power, B was a little better, C almost there and D well you be the judge. For some reason this took a lot more power than I normally use to cut such plywood. Main thing is it did cut without tags so the file is OK. Note in the image with A B C D the cut through differed even though the power was increased. C had a lot more power than B but had more uncut areas. This I think is down to the veriations in the wood. So there you have it. Look closely at the images, you may get some info from them that I have missed. Please note, I do not think this is a design that will be succesful at this size. The mterial thickness between the letters is to thin for it to stay together. After removing my attempt from the board it soon came apart. 0.78mm between the letters is far to small to hold it together.

Thanks for the efforts sir. I’ll play with my power settings and give it a try.

I would also scale it up. Will take longer to cut, but at leased it will stay together. Sorry for any typos I’m 85 and finding things like typing is getting difficult.

I’m having this same issue with a Jtech 24 watt laser on a Onefinity CNC. I’ve checked the gcode and there are no issues. The laser just cuts off for a second and leaves a gaps in the cut line. Have you been able to find a solution?

If you have tabs set to ON lightburn will leave tinny gabs In the cut path so that the item remains attached to the materials you are cutting. This prevents the cutout dropping. Look in your settings to turn it off.

Thanks Ron, I’ve already checked that setting and the tabs are disabled.

I was able to successfully recut the potions of my design that had gaps. When I generated a new gcode file for this cut I turned off the “remove overlapping lines” feature in the optimization settings. It then cut without leaving the gaps. I’m not sure if this was the cause of the issue, but I’ll test this theory further if it happens again.

Some of these anomalys are hard to track down. Sounds like you have found a solution to your problem.

Continuing the discussion from Gaps in my cut path:

I sent my laser and control board back to Jtech. I was told they found an issue that they are updating to newer circuitry. They are extending a “delay” from .2 to .75 which they think will solve my issue. I was told there was another unit they are trying this repair locally and I am waiting to see if that works for the other customer. I’m hoping I get it back this week. I’ll post my results. I’m hoping this is not a bigger issue than just a random machine or two. So far tho customer service is making an effort to resolve.

So the issue was the safety feature that shuts down the laser beam if the unit becomes dislodged from my cmc machine. When my machine move in a certain direction the vibration from my table setup tricked the sensors into believing the laser unit had come loose, thus the laser shut off until the vibration stopped. The solution was to either put a long delay (10 seconds) or so OR just turn the sensor off completely. I chose the latter and now I have no issue with laser cut off. Just understand that if this is your choice you must make sure your laser is very secure. If my bench were much more stable I may not have had this issue. But thank you to the people at Jtech for working with me.