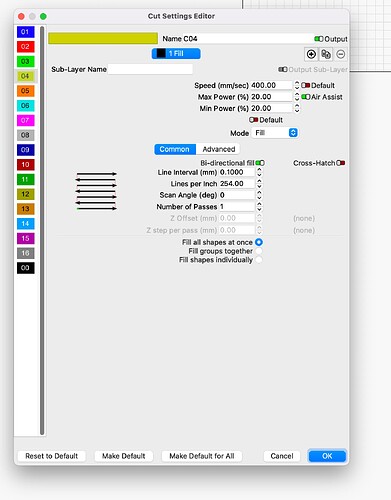

What interval are you using?

Most co2, with stock lenses, struggle to get a 0.20mm spot, limiting resolution to about 128 dpi.

Machining is machining, cnc just adds a computer to the mix … the actual tool operation may vary but the rest of this is the same. The led and the co2 effect are very similar as far as power and damage to similarly absorbed material, such as basswood.

Figure out what’s going on at the beam → material point. What exactly is the beam doing to the material…

An led is on or off. When you send it a 50% pwm signal, it is on 100% for half the time and off the other half. It’s a digital device… This would relate to 50% power, although it’s really power/time.

A co2 can operate at 50% power continuously… if you set it for 50% power, the lps limits the current hence the output power. A glass tube co2 is an analog device.

You might want to limit your speed, for more than @ednisley mentioned and ensure you’re using a reasonable interval for the response time of your lps…

The minimum response is usually placarded on the lps and is usually 90% output voltage <= 1mS (1/1000 of a second).

If this is the case and we use the worst case 1mS value…

Running at 1000mm/s will allow you to toggle the tube every mm, the best resolution would be 25.4dpi…

If you slow down the 500mm/s, it can react twice every mm and the best resolution would be 50.8 dpi…

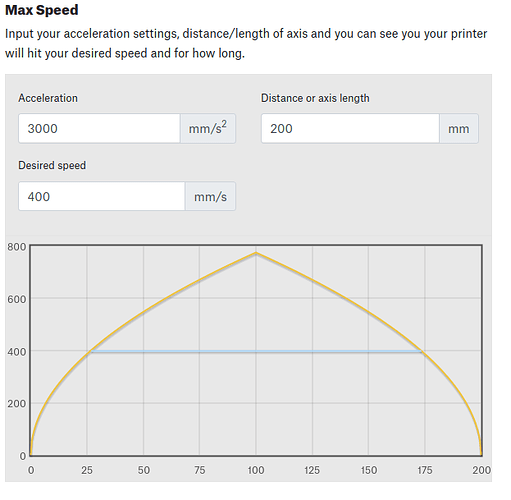

Just keep these in mind… hang in there, I’m sure you’ll get a handle on it. I’m with Ed, I think you need to slow down a bunch. You can figure out how much room it takes to accelerate to maximum speed using the calculator.

Good luck