Why do I get Error Code 11, i’m etching text generated in Lightburn, the error occurs in the same place on the second letter every time. When the same file is exported as G Code and run in Laser GRBL there is not a problem. I do need to run it through Lightburn as it has more controls than GRBL, can anyone assist.

What kind of engraver are you using?

GRBL is a controller/firmware type but there are manufacturer/model/type specific troubleshooting techniques.

Win 10 is nice to know but probably not related to the cause of the error in this particular case.

I’m using the Sainsmart 3018 laser engraver, the bundled software Laser GRBL, seem to be working but restrictive compared to Lightburn, which was working well untill the latest upgrades 2 of them in the past 10 days, hope this helps.

Computer is HP laptop solid state hard drive operating on Windows 10

“error:11” : _(“Max characters per line exceeded. Line was not processed and executed.”),

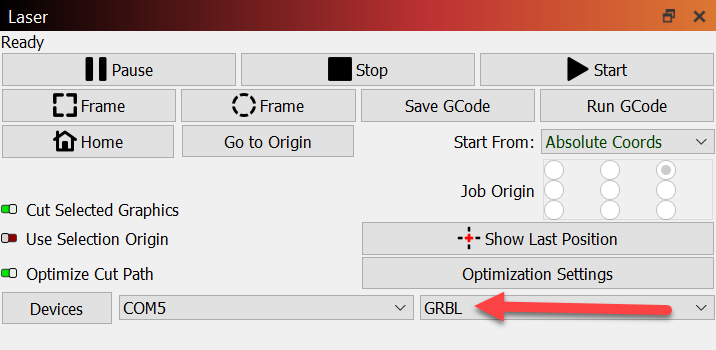

Please open the Laser window and let me know which GRBL variant you are currently communicating with your engraver from LightBurn.

Then open the Console window, and scroll back to capture the ‘Welcome Message’

I would like to make sure the GRBL variant matches the type of controller proclaimed by the welcome message.

i had 2 options when first installing 1, GRBL. 2, GRBL M3. i set it up with GRBL as recommended.

Excellent… and the welcome message?

I’ve got the laptop disconnected to do some other work, i will reconnect and let you know in a short while when I get back in the workshop,(no WI FI there), Thank you for your help so far.

Here is the welcome message from the console.

Waiting for connection…

wt����

Grbl 1.1f [’$’ for help]

VIGOTEC|CNC|V1.01|B20210204

ok

[VER:1.1f.20170131:]

[OPT:V,15,128]

Target buffer size found

ok

Interesting. V for Variable spindle and that’s it.

One of the most plain and simple GRBL set ups suitable for a Laser.

I’m not sure what’s going on yet but I have a thought on it.

Start up LightBurn, load up your text file.

In the Console window on the Right hand side there’s a switch that says ‘Show all’ make that green by clicking it and turning it on.

turn off the laser engraver head ( unplug the PWM connector if you have to )

run the job - when it gets to the place where it spits out the error we should see the Excessively long command line and maybe some other stuff.

copy and paste it into a response here.

I’m hoping it turns out to be a command that can be shut off.

I can’t see the cause of the problem yet.

Below are 2 files copied from the console

The first is the top row of text only.

the second is the entire file output.

if you give me an email address i’ll send you the file over, it will probably be easier to see what i am doing.

Thanks again for your assistance.

Target buffer size found

ok

<Idle|MPos:0.000,0.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

<Idle|MPos:10.000,0.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

[MSG:Pgm End]

Stream completed in 0:00

Project loaded in 8 milliseconds

<Idle|MPos:0.000,0.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

Layer Top Text

G1 Y-0.438S200

G1 Y-9.697S0

G1 Y-1.338S200

G1 Y-1.066S0

G1 X-0.1S0

G1 Y1.066S0

G1 Y1.573S200

G1 Y9.309S0

G1 Y0.591S200

G1 Y1.067S0

G1 X-0.1S0

G1 Y-1.067S0

G1 Y-0.744S200

error:2

Numeric value format is not valid or missing an expected value.

On or near line 34:

Job halted

Stream completed in 0:13

ok

ok

ok

ok

ok

error:24

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

ok

Second Pass

Waiting for connection…

Grbl 1.1f [’$’ for help]

VIGOTEC|CNC|V1.01|B20210204

ok

[VER:1.1f.20170131:]

[OPT:V,15,128]

Target buffer size found

ok

Project loaded in 7 milliseconds

?

<Idle|MPos:0.000,0.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

ok

Starting stream

$32=1

$30=1000

G00 G17 G40 G21 G54

G91

M4

M8

G0 X204.228Y4.246

Layer Border

G1 X0.754Y0.754F1600S0

G1 X0.018Y0.018S200

G1 X0.754Y0.754S0

G1 Y0.142S0

G1 X-0.754Y-0.755S0

G1 X-0.159Y-0.159S200

G1 X-0.755Y-0.754S0

G1 X-0.141S0

G1 X0.754Y0.754S0

G1 X0.301Y0.301S200

G1 X0.754Y0.754S0

G1 Y0.142S0

G1 X-0.754Y-0.755S0

G1 X-0.442Y-0.442S200

G1 X-0.754Y-0.754S0

G1 X-0.142S0

G1 X0.754Y0.754S0

G1 X0.584Y0.584S200

G1 X0.754Y0.754S0

G1 Y0.141S0

G1 X-0.754Y-0.754S0

G1 X-0.725Y-0.725S200

G1 X-0.754Y-0.754S0

G1 X-0.142S0

G1 X0.755Y0.754S0

G1 X0.866Y0.867S200

G1 X0.754Y0.754S0

G1 Y0.141S0

G1 X-0.754Y-0.754S0

G1 X-1.008Y-1.008S200

error:2

Numeric value format is not valid or missing an expected value.

On or near line 29:

Job halted

Stream completed in 0:13

ok

ok

ok

ok

ok

I don’t see a flaw in the Gcode at all.

Can I ask which VIGOTEC engraver you’re using?

Have you reflashed the VIGOTEC controller to run standard G-code?

Vigotec uses a Proprietary version of GRBL and I believe this is the source of the error:

I do not know why you aren’t having problems with LaserGRBL. Problems ‘should’ be occurring there for the same reasons unless you’ve addressed this somehow.

A developer outside LightBurn has been working on this issue for a couple of years.

In your case, I find this hack quite attractive and perhaps the best place to start:

Hi John,

I can’t confirm the exact model of the controller as there’s no markings on it, the manual that came with the machine is vague to say the least. I havent done any updates to the controller, the readings i sent you were done first thing this morning. I will try running a file that has been used before to eliminate possible problems in the generation of this new one, I’ll check out the links you’ve attached.

P.S

The engraver is the sainsmart 1830. Laser engraver or router machine. The connection is viaa usb cable the board doesn’t support WiFi connection.

Do you have more than one machine connected/plugged in? It’s almost as if you have two different separate welcome messages in the console window.

The USB connection can power a controller enough to respond to communication but not enough to move or fire a laser.

You have a very interesting engraver.

No its one machine, you just swap the heads out.

The two welcome messages are the same graphic run 1 after the other, after switching off some of the layers, to show you the different errors, this time 24 & 2, I did mention this in the related message. Does this give you any more of an idea, as also mentioned if you want i can send you the file.

As mentioned yesterday, I tried running a file (again text) that was generated and engraved within Lightburn without any problems, now comes back with error 24 at line 35.

I saved as g-code, loaded in to bundled software LaserGRBL v4.8.0, and it has run without any problems. Would it make sense to try to reinstall my machine in Lightburn in case something has gone wrong during the 2 recent updates as this is when the problems have arisen.

from this:https://www.3dtek.xyz/2018/02/19/grbl-error-codes-8/

Error 24 – STATUS_GCODE_AXIS_COMMAND_CONFLICT

Two G-code commands that both require the use of the XYZ axis words were detected in the block.

I think your controller is thinking it’s a CNC mill and is demanding a Z-input when it needs the spindle to hop out of the workpiece. GRBL 1.1f should be laser friendly and not demand a Z axis command.

Open the console window and type the following:

$$

then hit enter.

Copy and paste the report in a reply here. I must have missed something.

The other swap out head is a mill, i loaded up a new device and it worked perfectly, which $ command line needs reconfiguring from mill to laser, i already change $30 & $32 within Lightburn at the begining and end of the file to set up as laser, and then back to a mill for spindle speed and for no cutting on dead moves, can you tell me what others need to be ammended.

If you set it up for a laser via the ‘Start grbl’ and end the run with code in ‘End grbl’ to return to ‘spindle’ mode…

How does the laser work for manual control, such as framing?

I thought this needed to be ‘static’ while you were using it with Lightburn…?

Thought the ‘framing’ used the spindle pwm to control the laser…

![]()