I’m working on trying to get TiO2 to work on glassware (with rotary), on a 100w co2. I’ve read and watched all kinds of stuff, and and experimented a bunch. The issue is that I get chipping, which I’m trying to avoid, not just because I want it to look nicer, but when the image/words are black, the chipping removes it.

Things I have tried:

Speed: 300 and 400mm/s

Power: 12.5-35%

Jarvis and newsprint dither.

DPI: 150-500 (dot width correction 0.03)

Black %: 100-50

I’ve narrowed down a few things.

- speed doesn’t seem to make a difference, other than being able to go faster, bearing in mind power vs speed.

- Jarvis looks better than newsprint.

- 500 DPI looks better than lower. 500 is where I do pretty much everything after watching a very detailed video posted here.

- power seems to do best around 20ish. More makes it darker, but almost more…melty.

I have a little hair sprayer that I mix rubbing alcohol and TiO2 powder in. I don’t really have a ratio, I just mix till it’s a consistent white. I spray on a coat, hit it with the heat gun for a few seconds, and repeat for 3 coats. I tried brushing it on, which didn’t work at all. I tried using the air sprayer, which was ok, but seemed so thin that it didn’t even blacken. So I’m unsure if maybe my application could be better.

Clean up is just hot water, and a scrubby sponge. Then I lightly hit it with a brass wire brush.

I’m just trying to get black frost, without buying the $80/can laser marking paint lol.

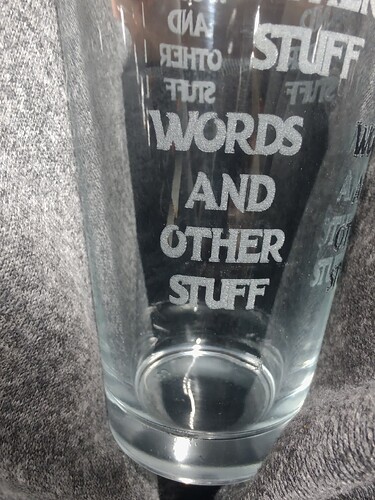

Pics included:

-

regular burn, no chipping, 400/20 Jarvis 500dpi full black image.

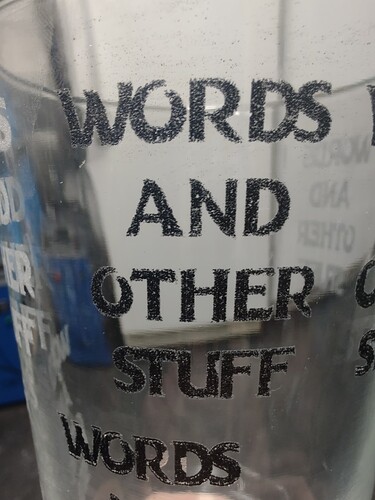

-

same but with TiO2

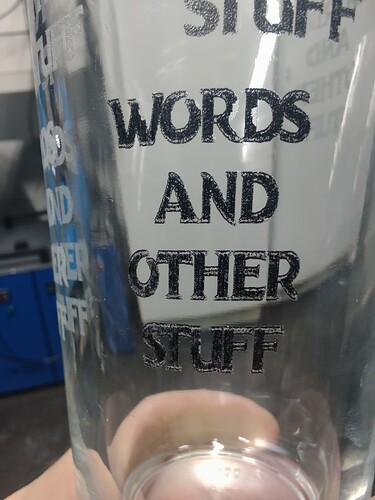

-

same but 35 power (melty)

Considering all of my other examples I’ve done tonight seem to vary in chipping, even when changing nothing, I can only assume I could be applying things better, or im totally missing something.