I had some success recently engraving Glencairn glasses with my Orator Laser Master 2 with the rotary attachment.

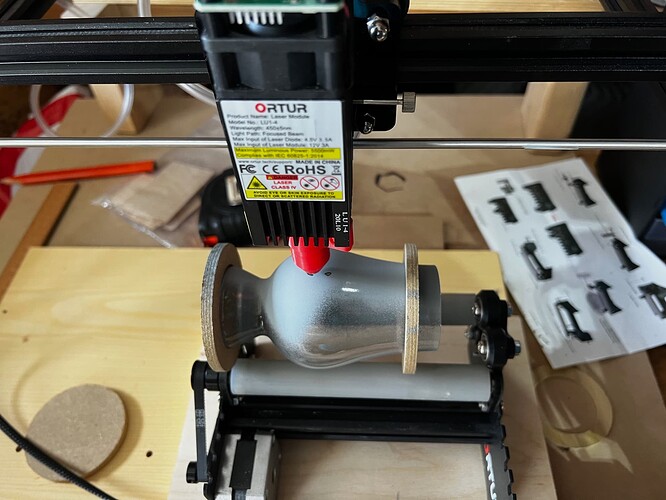

The first problem to overcome was the unusual shape of the glass. To address this, I made some discs that were slightly larger than the widest circumference of the glass. I then made a small depression in the discs that was the same size as the base of the glass. I also made a ring with the same circumference as the disc, and with inside circumference of ring slightly larger than the size of the upper part of the glass. A CNC was a big help here.

I hot glue the base disc to the bottom of the glass (double stick tape proved insufficient), and a simple friction fit of the top ring was sufficient.

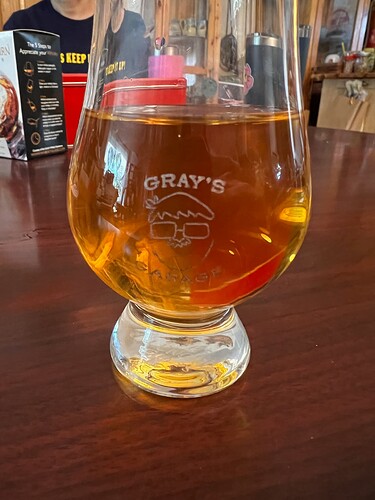

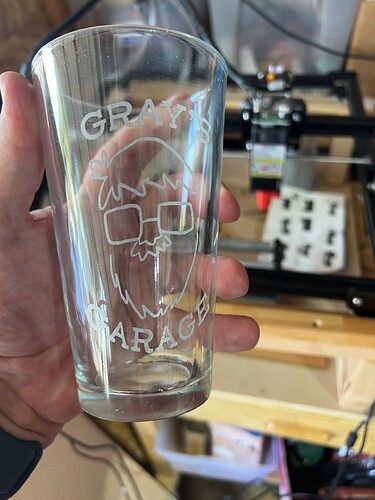

This allows the glass to rotate predicably, but limits the design to widest part of the glass–good for a line of text like a name, or logo.

First couple of tests worked well, but some production runs ran into a new problem-my initial runs with the first couple of names ended up cracking the glass–my theory was that the font was too big, and the power was set too high. Broke 3 more glasses and ruined one with a setting that was too low before I found that for this application, 60% power and 1000mm/min, PLUS air assist, seems to be the sweet spot. A picture of the set up below. Had a successful run of 10 glasses today.