I feel that. I have 4 3d printers a heat press system, a vinyl cutter, and even an industrial sewing machine all in my workspace so I am already cluttered lol

The more I think about it I might redo my laser enclosure into a vertical lift of some sort. I also have my commercial vacuum dust bagging system in the basement that hooks up to the router when it is running

when I get unceremoniously conscripted into going shopping for groceries or something with the wife I base some of my decision making on brands and such on packaging LMFAO

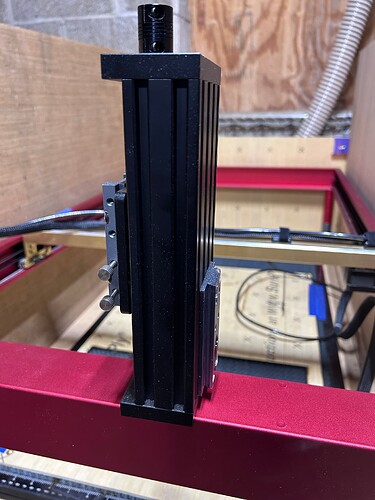

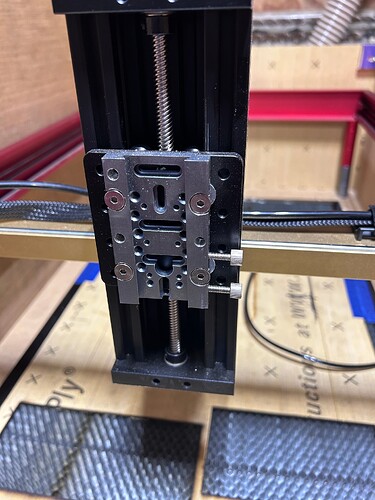

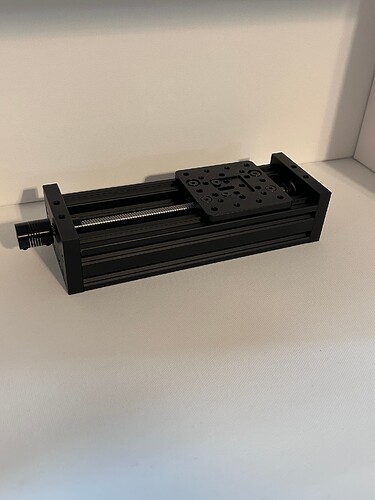

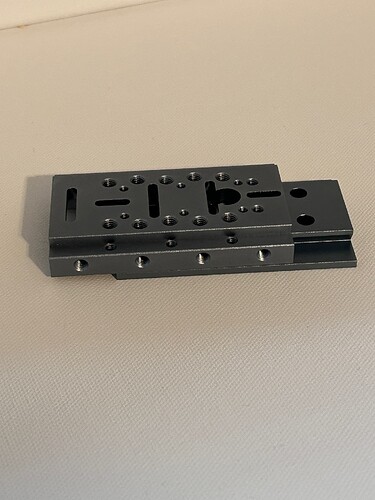

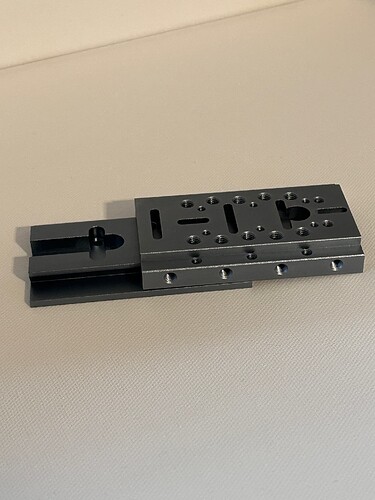

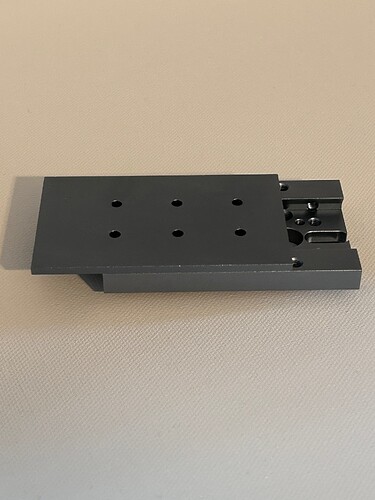

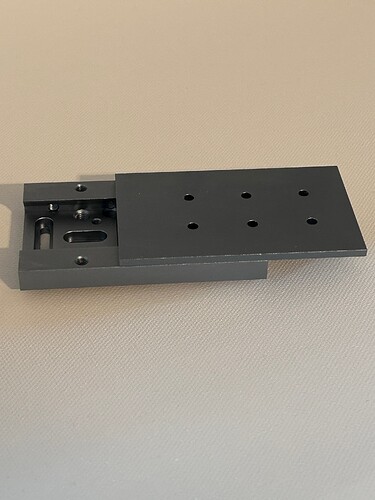

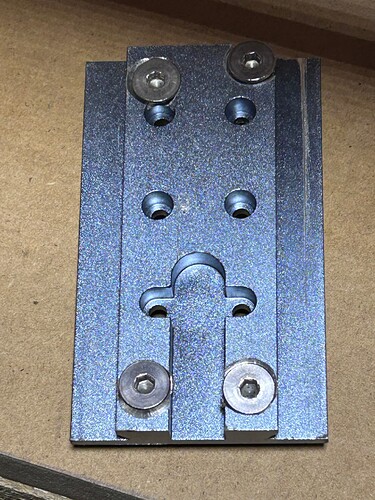

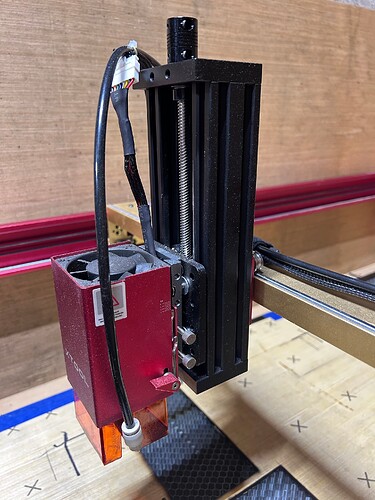

I bought parts from amazon to put a z axis on my extended xtool D1 Pro. i will include pics and a video i made. it works well as long as you are not running it too fast.I put the video together without editing, so don’t be too cruel. LOL

I did the same thing (King Gubby) with with my S30. I use it a LOT because I get nearly 4" of overall adjustment.

Yeah, mine seriously fails the high speed accuracy test on anodized aluminum, but looks fine on wood and glass.

I was noticing the same problem with mine on taller legs as my laser head has weight to it. That was one of the main reasons lowering the work surface was quite appealing

I converted a cabinet I made for my carnival popcorn machine into my laser station.

Built a lighted cabinet for the laser. Built a small platform scissor lift with ball screw that provides a good 10" range of verticle up/down. Drill motor makes it move or turn screw by hand. 6" 240 CFM exhaust fan in bottom with 4" duct fan at window outlet.

Also have xtool basic air assist, but it only gives 3-5 psi of air. I added a separate regulator to enable using an air compressor in case I want 10-20 psi. You never know, sometimes more is better.

Popcorn machine needs new home

great idea and usage of a cabinet…