Hi guys,

I am having a small issue.

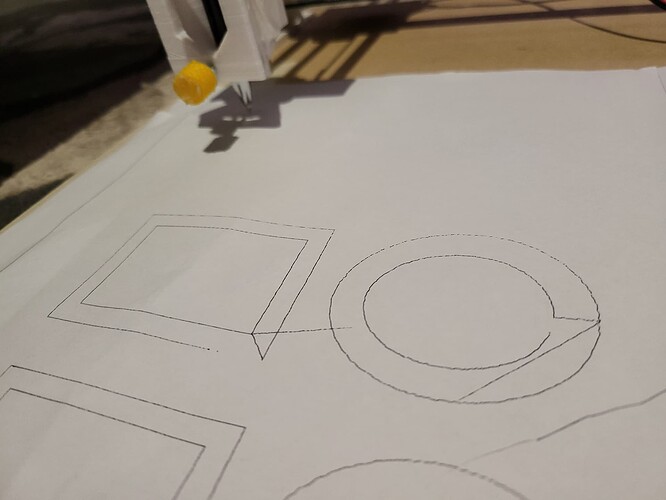

I am using an Arduino + CNC shield loaded with GRBL to control a Pen Plotter.

Using an serial monitor I have set up my limits and settings.

My machine also raises the pen with M3 S90 (Laser Off)

Drop pen with M5. This is a physical limitation of my design of the machine.

Its there an easy way for me to adjust this like you can with Marlin.

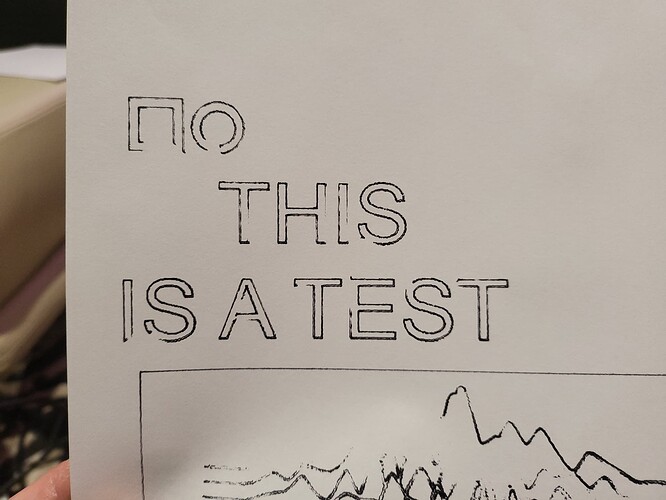

I know this can work, all I need to do is swap M3 and M5 l.

I know this because I can save gcode, open gcode and use replace all then use run gcode and it works, however those becomes a bit tedious doing this manually.