Hi, new to the forum. I Started off with the Elegoo Phecda 20W diode running GRBL via lightburn core. I used to run a 200W Firestar CO2 laser at work which I also helped build the controller for with a mach 3 board. I Just got my G2 Max yesterday, so I’ve only had about 2 hours to play with it. Long enough to discover the first round of bugs and hurdles.

I came across this thread after scouring the web for tips and tricks. Wow, this has been a lot of great information. Thank you, @Aaron.F ! I’m hoping to pick your brain some more.

I apologize, because I have a couple of questions which might be somewhat off topic.

- My red lines are off similarly to the OP. I’ll be working through your suggested fixes tonight.

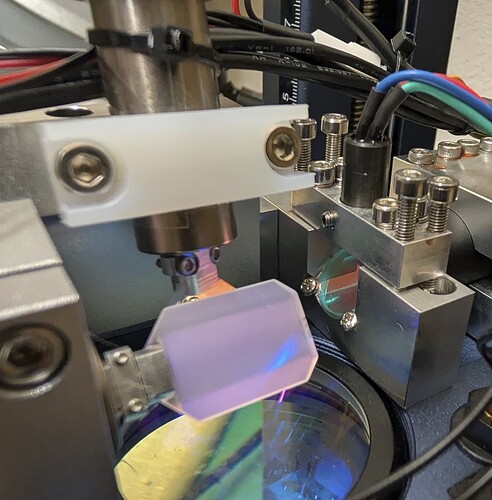

- I’m trying to cut and engrave 1mm brass, and having some difficulty. More on that below.

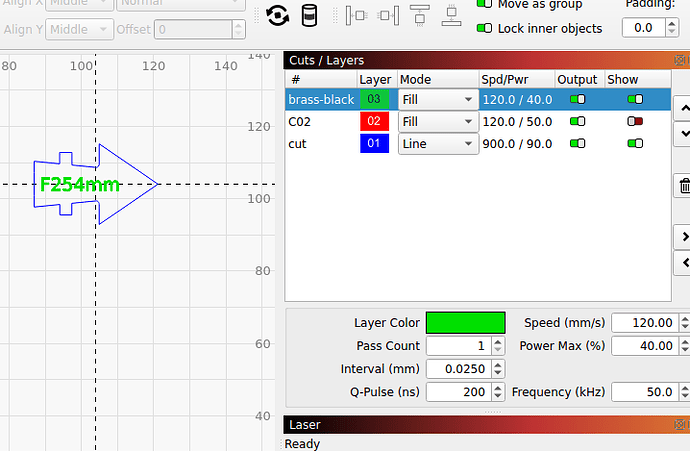

- After briefly trying Glaser and finding the interface inferior, I’m trying to switch to lightburn pro. but getting weird results. I’ve also found some suggestions here that are likely to help, and will try them tonight before I pose any questions.

So, for my brass cutting question:

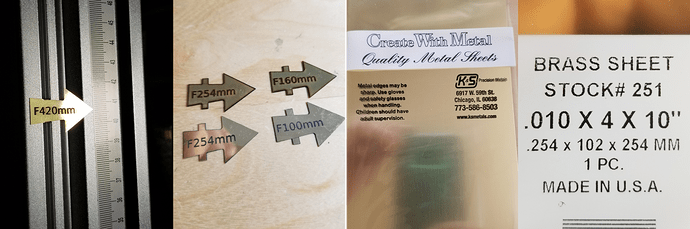

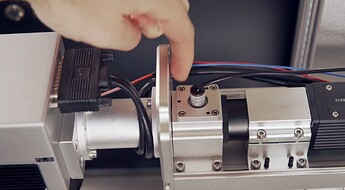

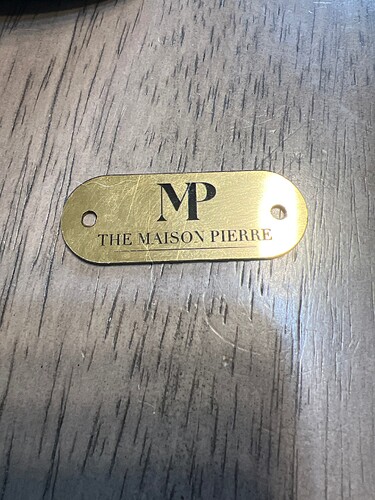

Got Glaser running ok after figuring out that the supplied USB cable was no good. Ran some test pieces in 1mm brass with the intent to engrave dark text and then cut an outline for some custom tags.

First Trial:

I used the recommended settings from barchlaser.com to start with for the dark text and cutting.

Dark engraving:

Speed 150

Power 90%

Frequency 60

LINE SPACE: 0.02

Did not do this:

HATCH : 1

HATCH type: Bidirectional

ANGLE: 90

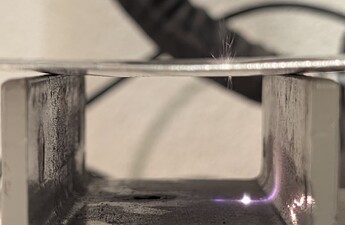

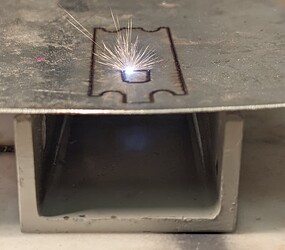

Text came out dark but raised rather than engraved, like it basically burned the brass to slag but left it in place. Cuts were very shallow and also mostly just a puddle of dark slag in a trench.

Cutting:

Speed 100

Power 90%

Frequency 37

WOBBLE DIAMETER: 0.30

WOBBLE DISTANCE: 0.1

passes 5(not mentioned by barch, but the promo videos for the G2 showed it cutting in 4 on .5mm)

But didnt do this:

HATCH: Bidirectional

HATCH angle: 0

LINE SPACE: 0.5

Second test

Tried the published settings from Gweike for engraving brass and it took off a lot more material(≈.5mm), but was not dark at all. 1500mm/s, 60%, 30khz, 200 passes

Cutting I tried their published settings as well, but I can’t find them now. I believe it was very similar to Barch’s recommendation, except frequency 30, and I tried 25 and then 50 passes.

Even 50 passes didn’t cut through. But it was close enough that I can see a line in the bottom of the brass along the trench. This took a while for such a small piece. Do you have any recommendations for how I can get closer to the awesome 4 pass cuts at .5mm Gweike shows in their promo vid?