Good day,

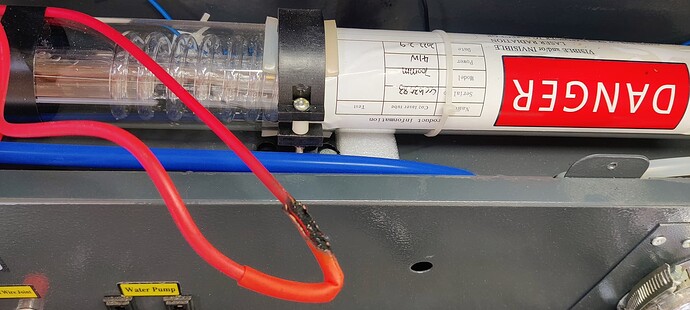

Heard a static crackling sound coming from my laser. Omtech 40w btw.

Then the laser stopped firing. Opened the back and pulled this wire up to find that it was burnt. Can I just splice this back together or is there something else I should be looking at?

The voltage increases until the tube lases… this kind of arcing usually occurs when the tube isn’t operating properly and the voltage gets too high for the anode wire insulation…

My guess is that you have lost the tube…

Does the tube look physically ‘intact’?

You will have to splice it… you have a relatively new tube did it show any signs of a problem?

![]()

I spliced it and tested it and it’s working as normal now. I generally run the laser around 40 to 50% and rarely for more than 15 to 20 minutes at a time.

Good it’s working…

Doesn’t really tell me anything… what kind of mA is it showing at 50%?

![]()

Now that the wire has been spliced and resealed with heat shrink there is no more static noise.

All it takes with hv is a pinhole … be cautious around that splice when working back there. The anode can be at 30kV

![]()

Actually. The control on the laser is set to 60% and the cut settings are at between 40 and 50% so really laser is running at around 30ish% most of the time.

Oh I’m not going anywhere near that splice when there is any power to the machine at all. Lol.

I may actually 3d print a sleeve to cover the area with the heat shrink just to double secure to be sure then is no protruding wire anywhere. Lol

Not a good idea… purchase some hv type tape of something to cover it with.

A 3d printed object may have ‘holes’ where the hv can pass … and it will reach out and touch you…

Even with power off, there is a high potential there for a substantial amount of time. The lps is a very high impedance supply and the voltage doesn’t easily ‘drain off’ when power is remove.

Where are these set and how do you figure 30ish%?

![]()

Noted. Hv tape it is.

I’d think 69kV of insulation would be acceptable… ![]()

It’ll ‘touch’ you if it has a chance… it’s not like it’d kill you, but I’m equally sure it wouldn’t go down as a ‘good’ laser experience.

![]()

Lmao. Either way I don’t want to find out so I’m gonna wrap it up to at least feel a bit more secure.

Thank you as always.

Is it strange however that Omtech shipped it with just standard heat shrink on that spliced wire?

Unless it was ‘reworked’ by OMTech, I doubt they had anything to do with it… and probably why it had an issue to begin with…

Standard heat shrink should only be used within it’s voltage range… If everything is working and there was heat shrink on where it arced, I’d be suspicious…

I suspect it’s from the manufacturer in China.

You make an assumption that the manufacturer in China had a clue as to what they were doing… or cared.

![]()

Agreed. I think I was assuming that Omtech would have noticed that as a potential issue and corrected it prior to shipping with their name on it.

Oh well. I’ll use my diod laser until I receive the tape and wrap it all up.

Oh and I was thinking about your amperage question and I don’t believe on the gauge that I’ve ever seen it jump past 20mah.

Like any meter it reads only rms values… so if you set the layer for 50% pwm (power) and meter reads 10mA, it’s actually 20mA for 50% of the time. You’re drawing twice as much current as you think or displayed…

Pwm only control how long it lases during a ‘period’, not the power to which it lases.

![]()

Ohhhhh…

Good info.

So I should be looking to keep the power under? What level?

I keep it at 60% on the settings of the machine it’s self.

The current limit is usually specified by the tube manufacturer…

As I stated, percentage of power is a pwm setting not how much current that’s flowing …

Where did set this?

![]()