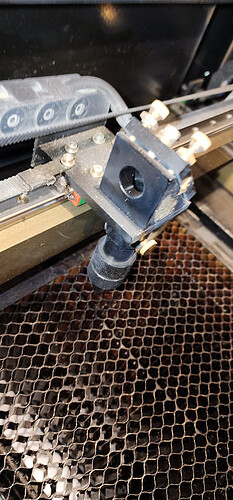

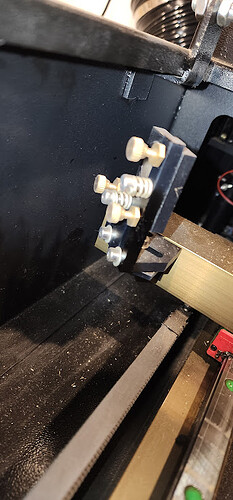

What I found with my OMTech and probably all the similar machines, is the is no way to do a Z adjustment on the head.

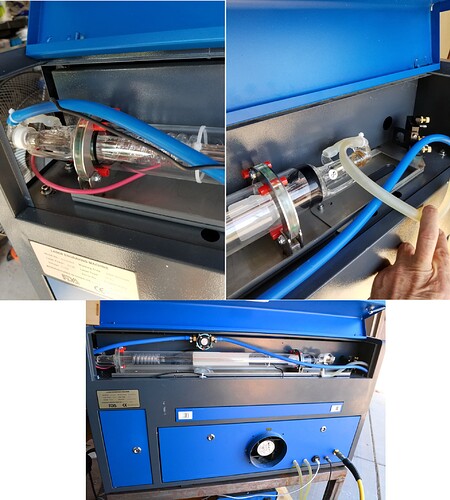

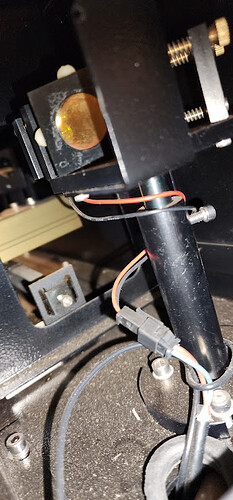

I replaced my original tube holders with one of Sadlers tube mounts. It will allow me to go to 55mm by removing the spacers… The mirror mount is part of the tube mount, making it easily adjustable and the exactly perfect angle. You can see the acrylic spacers that hold the 50mm instead of the 55mm tube.

I do mostly engraving, at low power and when I cut, I rarely have to cut acrylic above about 6mm (1/4"). I do all of what I need to do with 10 to 30% power, which relates to about a 4W - 13W range, except when cutting… I can cut at 100% power if I need to, it isn’t going to break it, as it is within the specification and can’t exceed that. Usually I cut around the high 80 or low 90% range… This is a grade A tube with documentation of it’s operation from the manufacturer…

Having a lot of power is only good for cutting thicker stuff… not so great for engraving… you lose the bottom end of the power of the tube.

One of the good tube manufacturers stated on their specifications that their 60W tube has a power range of 12W to 60W… This indicates to me that they do not expect the tube to be operated at anything below 20% power…

If you needed 4W, that wouldn’t be in the manufacturers range of operation… the best you could do is three times that…

I believe as many do, that it can damage a tube to run it at or near it’s lase point… The gasses are not responding like expected and can shorten tube life.

I spent lots of time looking at burn spots on my tubes output at low power…

I have a lower limit based on the target results, not if it lases or not.

I bought a China Blue 50W machine from OMTech… I measured the output with a Mahoney power meter and it was 44W, which is about right for the 880mm length…

Clearly OMTech is ripping us off by knowingly inflating the specifications. I think they all do it to some extent.

If the need is to drive a tack, would you pick the tiny tack hammer or a 20lb sledge? Both are hammers, do the same type of job, which gives you the best control, precision and results?

So, in the end I replaced it with a Cloud Ray 40W and have been very content… and it is 40W…

Big is not always best, it all depends on what you want to do…

Of course, all of this is just my opinion and position…

Good luck