here are all my light burn settings for comparison.

I am running GRBL 1.1h on the MKS DLC 2.0 motherboard on this machine, I am working on another that will use the mega2560/ramps1.6 hardware.

I have added a defaults setup for the cnc2-6550 frame in the defaults.h file and made the following changes in the config.h file before compiling and flashing to the mks board.

This puts the machine origin 0,0 at the front left on machine or bottom left corner on any artwork, not sure if this setup is standard but its what I am used to working with for pcb design and I like the machine to do it for me when i hit home. I am planing on using limit switches in all corners but I am going to port to the mega2560 and ramps1.6 so i can use a proper Z axis and rotary, all the better now that i can use grbl to square by y-axis with dual steppers.

I have attached the saved file for machine settings

cnc2-6550 mod 30w Lasertree MKS DLC2_defaults.lbset (5.4 KB)

I have only had the unit for about 2 weeks now and decided to do a lot of modifications before testing, did the first tests last night with these results, i was playing with power and focus settings in the files. The markings on the burns are wrong, i was lazy. The shade wheel has the max power set to 50 and speed of 3000 mm/m, the bigger one is not on 6.5mm its 2.0mm text at 3000mm/m 80%, image 3000mm/m 50%, and the cuts are 220mm/m at 100% 3 pass. The unfinished large test was focused on the surface of the cardboard, the 2nd one with the image the focus was on the work surface below the cardboard or aprox 2mm lower. I had an issue with not getting variable power on the diode with the test without the image, that one was cut with laser mode turned off which would cut, but could not do shading, i have since fixed that and the one that is cut out complete is with laser mode on.

Here are some build pics of the machine itself, anything in the pictures that is steel blue are 3d printed on a modified makerbot 2x machine (replaced extruders with dual e3dv6 hot ends) in Eco Tough 2.0 PLA filament.

nice looking machine but be mineful of those show door wheels because the bearings are not up for much wear and staying tight. Years ago, when RepRap was the only game in town for 3D printers, anyone wanting to use extrusions had to use linear rails and they were over $100ea. Some tried the show door wheels on Mini Kossel carriages and they worked but accuracy was poor. Someone turned a bunch of delrin into inverted “V” slot wheels using 2 bearings and they worked great. One of my machines still runs with those wheels after over 5 years.

I don’t know who came up with the dumb Ender wheels but now those are the norm and are cheap and available everywhere. Those are way better than the shower door wheels but are thicker(2 bearings).

Thanks for the tip, can i assume you are referring to these, if so I am going to order a set and get rid of the original ones that came with the frame.

https://www.amazon.com/CCTREE-Printer-Plastic-Bearing-Creality/dp/B07DC99DPV

Yes, those are the ones used on the Creality Ender 3D printers and most of the diode lasers I’ve seen.

The design is not so great because they put forces on the angled faces of the wheel but will still work way better than the shower door wheels.

On my Mini Kossel, this design works way better because the inverted “V” is used only as a guide and all the forces are on the flat part of the wheels. It’s with Misumi extrusion so I don’t know if they’ll work with the other extrusion out there.

Thanks again for the information i ordered a set of the first ones and the ones in your last post will see what i will need to modify to get them on my unit when i receive them.

Everyone,

Once again, thank you for all of your help and suggestions. I am seriously at a point that I am ready to give away my laser machine because it is driving crazy.

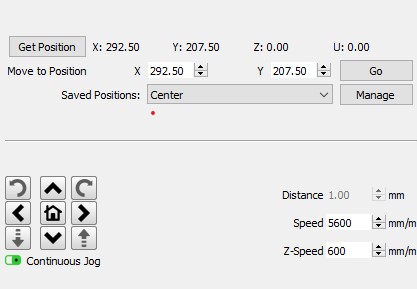

I even ended up re-installing all my CNC drivers, re-flush the GRBL, re-install LightBurn, and anything else that I could think of. I am not able to set either user or current origin setting. My coordinates don’t show up correctly on “Get Position”. The “Move to Position” function does not work for me either

Again, I was able to do this successfully until the last week. I have done and gone through every steps, one by one, to resolve the issue but without being able to precisely set my starting points on my projects, I will have to just do so much guess and hope work.

I would be glad to do screen sharing and show what this issue is but seriously, as much as I LOVE my machine and this software, I am so ready to just call my laser projects failure/goodbye and go back to V-Carve and CNC work.

Would someone be able to help please?

Thanks,

Allen

@akhaligh it seems 2 other people decided to post on your thread and you failed to respond to the lead developer’s post asking you to perform a couple of tasks and report back.

Regarding your last post, what CNC drivers are required for LightBurn to operate your machine? Are you talking about USB drivers? Completely unnecessary if LightBurn can communicate with the machine.

When you re-FLASHed your GRBL firware onto the machine, was there a step to reset onboard flash configuration data? In this post it looks like he lists commands to clear flash data and reset to defaults:

Doug, Thank you so much. You definitely pointed me to a right direction.

I had the same exact problem as Steve did in his post. Same exact issue!!! I took his advice and used RST- and basically flushed GRBL. However, I realized that everything, even my home settings were not working anymore. Also, I realized that there were multiple versions of GRBL showing up when I started LB. One was from VCarve and the other one from PicSender.

To make the story short, I wiped everything off of my machine and started with a new Windows 10. Then, I installed X-Carve’s Easel driver and Lightburn. The problem is gone. I can home successfully and even set my origins.

Thanks again for all your help and suggestions.

great news!

Yes I have suddenly found it impossible to set the origin to 0,0.

It sets origin only to design shapes. I tried everything.

In the end I had to create a rectangle at 0,0 and run from that.

It hasn’t been like this before.

I have been having issues with set origin as well.

Where did you buy those limit switches?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.