Okay, her we go. I have searched posts/topics and nothing seems to match my problem.

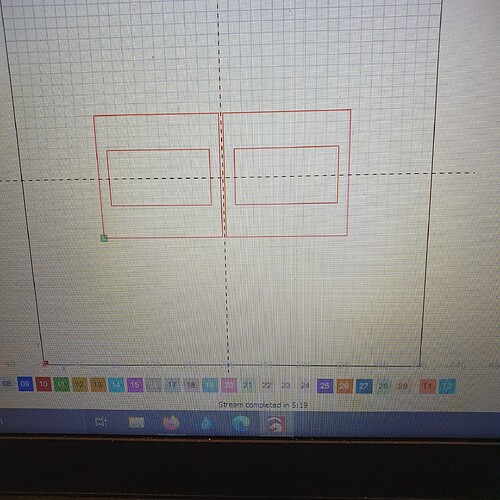

I am attempting to make some simple packing pieces. The outline is a simple rectangle inside a square, however the square is being burnt in various positions on the y-axis. It stays relative to the rectangle in the x-axis though. Both lines burn the correct size. I even tried burning 2 next to each in the same burn, and they were both different.

This is driving me nuts! Please help guys. I have attached a photo of the drawing and what was burnt.

You’re likely losing steps during travel moves between burning.

Check belt tension particularly on the Y-axis.

Belt tension appears to be fine. Re-tested and is the same.

How are you determining this?

Additional things to check for:

- Check that the pinion gear is properly secured onto the stepper shaft. The grub screw retaining the gear should be positioned against the flat of the shaft. I don’t think this is likely as you’d likely have more artifacts during the burn itself but still worth investigating.

- Have you changed any of the GRBL configuration on the controller? If so, what?

- What speed setting are you using for these tests?

Belt tension as per setup instructions, however the x-axis motor was struggling at the point it traversed from one shape to the other, so am going to strip it down tomorrow and see if i can figure this out.

Belt seems in good shape though.

Thanks for your help though. Let you know what i find… hopefully tomorrow.

Quick question though… the motor struggling while going from the corner of one object diagonally to the corner of the other object wouldn’t be putting excess strain on the motors since both are working at the same time during that traverse? Just a thought.

There should be very little resistance across the entire plane of travel. This suggests you may be overtensioned. That could cause some of what you’re seeing but doesn’t seem consistent with the overall burn. Still worth investigating.

If belt tension is good I’d recommend a complete mechanical review to make sure you’re eliminating any potential for lost steps.

So finally got time to have a look at it. Seems the bottom right x-axis roller was too tight on the rail. Adjusted it very slightly, re-assembled and tested. All fine now!

Thanks for your help! Am going to have to use this place more often.

Again, thanks.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.