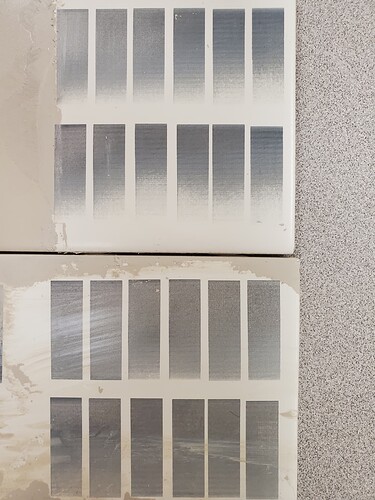

I don’t know if this is a software or hardware issue…I have 3 N40630s with 1 just being replaced today, so it is fresh out of the bag. The all perform the same task, Norton tile method, at drastically different power %s 1 does black at 60%, 1 at around 93%, and the other must be at 98% or above. When I perform this task in grayscale I get vertical lines in the scan, when I perform the same image with Stucki dithering I do not. Since I have 3 machines I have tried each module on each machine…the power settings and lines remain the same independent of the combination of module and machine. I have also tried each thru a powered usb hub and straight connection to the computer…problem remains the same. I have purchased new power supplies with grounding prongs to try…problems remain. I am using the most up-to-date Lightburn and windows 10. Could it be my computer? Lack of ample ram? I am pretty much at my witts end.

Visual aids could help understand the problem better

Grayscale is normally more prone to show issues of processing though.

But dithering should roughtly show the same results.

Have you focused these individually or are you using the same gap for each one?

Focused individually

Maybe that’s just the difference between the machines…

Using grayscale it states “this is variable depth not shading”

Two of the three machines are within 5% of each other.

Do you have a watt meter? Might give you a clue…

Not so worried about the differences in powers…I understand that every diode has different power parameters…more concerned about the quality of the output…I am currently burning the first image with the relpacemwnt laser module…soon will be able to see if the lines are present in an actual scan instead of a test pattern like above

Try something like this in 1 tile, each module 1 test

So they are comparable

Adjust speed to your usual range of speeds on tile

Default is 3000mm/min

At least it would give you a comparativeOrtur Power Test.lbrn (46.9 KB)

However from your image looks like focal points arent alike between them.

Gil…right now I am in the process of creating the same image with each module on each machine…I plan on doing the newly replaced laser module on 2 of the machines tonight…I will have the comparison in about an hour.

As a back story that might help. I have these 3 machines, an Outur Laser Master 2 pro and a 40w Chinese laser. I see the verticle banding in all of the diode lasers. I was starting to wonder if it was a problem with the cleanliness of my electical input so I inserted a power conditioner into the mix…I still get the banding. None of the machines or modules (-this newly replaced one) had this issue when I first got them. I also forgot to mention that I am photo editing the pictures with Photoshop to 300dpi, using the same dpi, settings in Lightburn, and ensuring I don’t adust the image size in Lightburn. Again trying all the tricks I know.

If you can try to add in your test a 45º angling it would confirm if its a band issue.

Any changes on the Pro GRBL settings?

P.S. Belt issue not Band issue

No…I have been working with your tech support, I believe you, and we tossed it around on your machine and you ended up sending me a replacement module as well…given there were other issues with that orig module than just the banding…i just got it at home today and will be experimemting with it tomorrow…last time we talked we reset all the settings just incase something got changed by accident. I am almost fully convinced that the banding has something to do with some setting in Lightburn because the program is the only commonality between all the machines. When I first got the machines LB was version 9.22-9.24 and all was good

Gil…I’m talking about the vertical bands in the scan not the physical belts…I don’t think I have a tensioning problem.

I know this is wayyy off topic. But I just wanted to say how great it is that a brand pops in and does tech support here. And also how awesome LightBurn is for allowing it. TBH it would be awesome if more brands were here.

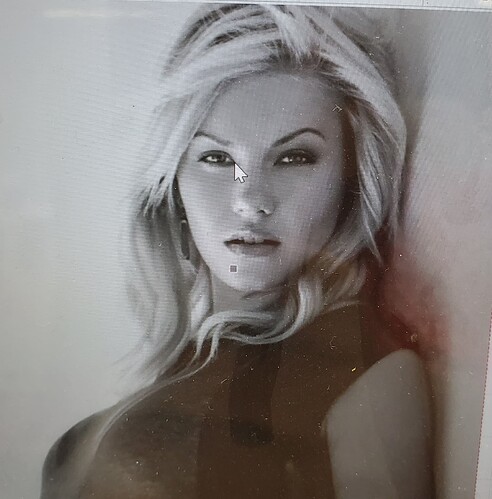

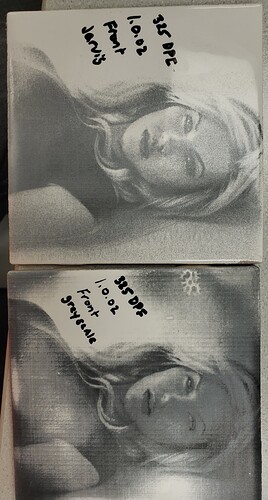

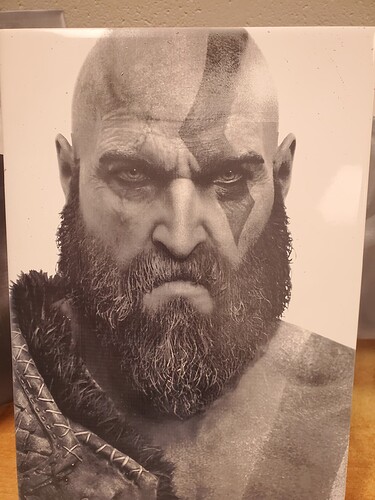

So some messing around and some interwebbing lead me to a few things…I read on a couple sites that greyscale is not the most suitable for tile engraving…true or not I don’t know…I used it in the past and had few problems…here is a picture I did on greyscale as well as jarvis dithering straight in Lightburn…the dithering came out way better (settings aside as I got the greyscale one a little dark) They were done with the same machine and laser module. My next plan is to dither with Photograv and see if it was worth the money I spent on it…this is a continuing saga because the first couple items I produced in greyscale on tile looked absolutely amazing on these machines and this is before I thought I knew what I was doing. Now that I have experience and a little knowledge my products are of lesser quality…this has to be a me problem because I have looked under every rock I can think of…anyway. on with the pictures…

And still striving for something as good as my very 1st