Hello folks,

my name is joachim and I’m new to you in the forum and also in the laser topic. Thanks for the admission and I hope that we get along well here. I’m really looking forward to working with you.

My English is unfortunately not the best and so I work with a translator and hope that you can handle it

To my surroundings:

My laser is a do-it-yourself brand. It is a converted CTC i3 A8 printer to which I have strapped a 15W diode laser (Zeus). I am currently still running the trial version of Lightburn and I am very willing to buy it if I can achieve the results I want with it. Unfortunately it is so that at the moment due to my ignorance the results are very bad and the joy is very clouded. but every beginning is difficult, that is clear to me. about my results: the normal engraving of fonts as well as cutting them no longer presents me with any major challenges. that works very precisely and surprisingly well.

Engraving photos, however, is a nightmare. I have now tried to prepare a high-contrast picture from the Internet and just engrave it as shown in the videos. total nil.

I don’t understand the interaction at all. The technical framework is clear to me, but I am not able to set the right parameters.

I’ve played around with the settings in Lightburn, but that’s a fiasco. The preview images always look very good and the result on the laser is disappointing. It’s not even close to good that i could say ok now you can work on it, it’s just bad and i don’t know where to start.

I’ll upload a few pictures where you can see the settings as well as the original and what came out of it. I would be really grateful if you could actively support me here so that you can see from my results what it should actually be.

Thank you in advance.

Now for the pictures

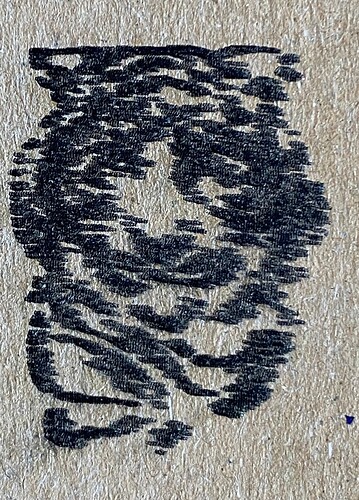

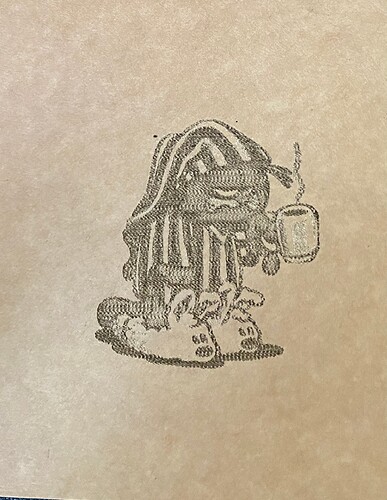

The original image from Googel:

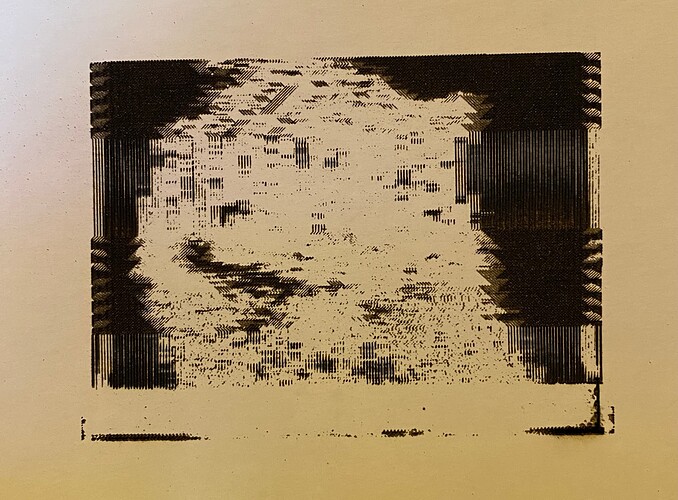

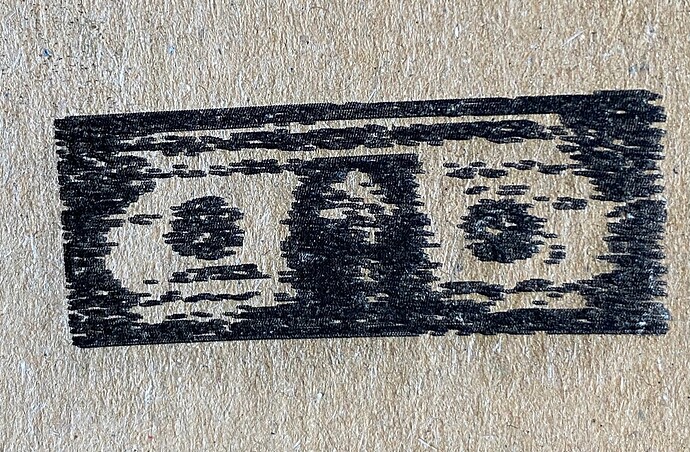

The result from the laser on a cardboard box

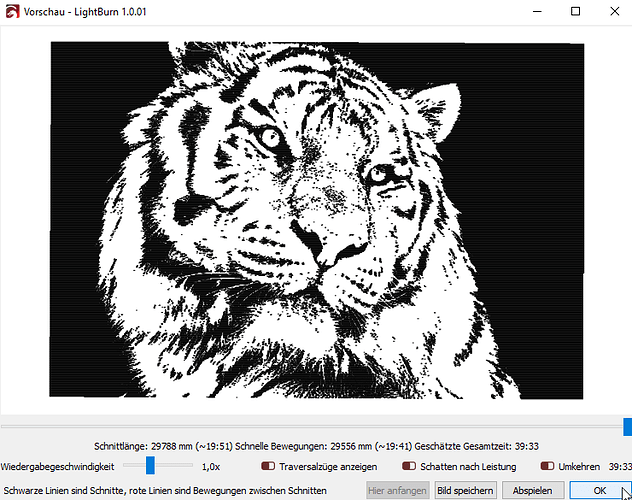

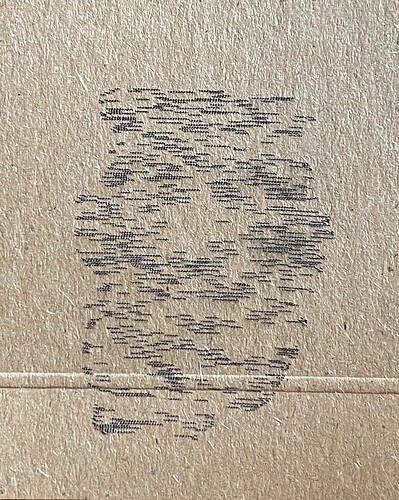

Lightburn preview

Unfortunately, can’t upload that many pictures

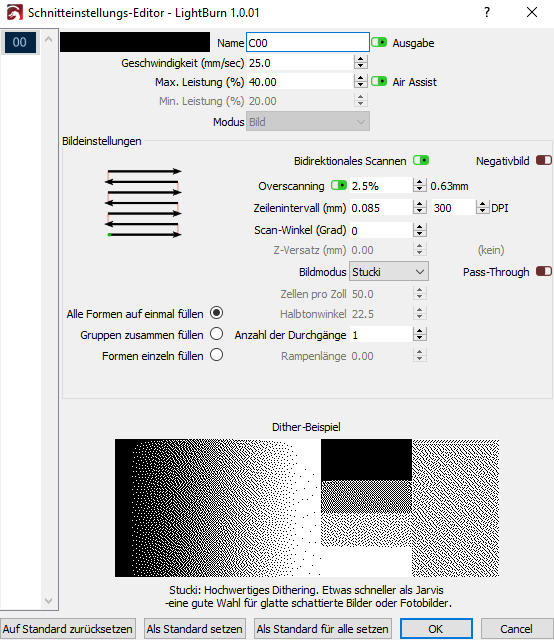

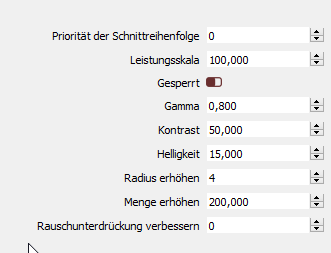

Settings

I don’t know if it’s the performance or the speed or the DPI, … Please help me that would be really great

Best regards

joschy