Hi, i have a chinese laser SH-G570 which looks to be a copy of the mf-2028 100w. It has a manufacturer date of 4/5/20 and i just bought it used from a guy. But now he will not return my messages and didnt give me the lightburn license as he said (yikes, what else is wrong ![]() ) He gave me upgraded lenses (not installed yet) and said he had an upgraded head, but now im not sure if he installed the head or the one in the box is the new head? New to lasers. So question, is the head on my bench the upgrade, or the one installed on the machine? Whats the brand and where can i get instructions on how to install? Thx!

) He gave me upgraded lenses (not installed yet) and said he had an upgraded head, but now im not sure if he installed the head or the one in the box is the new head? New to lasers. So question, is the head on my bench the upgrade, or the one installed on the machine? Whats the brand and where can i get instructions on how to install? Thx!

Also, this is the lens that came out of the head currently in the machine. It measures 18mm, im no expert, but looks like its time to replace. Its too small to fit in the other head, which makes me think the head on my bench is the “new upgrade”? Instructions on what lens to buy and how to install all this would be super awesome.

My first thought is, have you seen the machine in action? Do you even know if your CO2 tube is ok???

I hope for you that he hasn’t cheated you with anything other than the LightBurn license…

The lens shown looks somewhat “undersized” for a 100 Watt laser, not so much in the diameter but more in the material, maybe it was meant for a 40-50Watt tube, who knows.

The laser head that is on the table is the one you should mount, if it is the right type, it is no problem (see if the bracket fits the machine). The lenses are larger as in the original, so measure it and possibly order new ones, which are designed for 100 Watts.

If the fitting of the new head does not fit and you want to get started with your machine quickly, you can easily also buy 18mm lenses which are suitable/calculated for 100W, cost approx. $25 online. But later I will probably use the other head, it has better options.

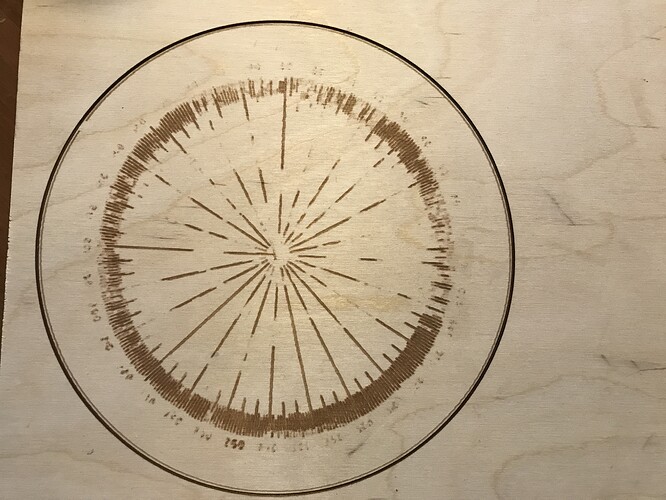

He did run this protractor (see pic) while I watched, its pretty bad but he assured me that was due to mirrors being misaligned after he transported it from his shop to his garage. That seemed logical at the time. Im hoping dirty, out of align mirrors, and a lens being so dirty is a good reason for how this looks? And not the tube? I did see some examples laying around of his logo that looked very sharp and clear. And a finger joint box that looked good.

So, any idea who sells those heads? Looking at it, i dont see any clear cut and simple way to install the new head. Mounting bracket is completely different. Also, i dont see where to install the laser pointer anywhere outside of fabricating one.

Protractor is 8” diameter.

if you have installed your laser, including proper cooling, you can do a quick test on a target disc on mirror 1. 0.5 sec or shorter with as little power as possible, but enough to give a spot mark of 2-3mm on target. With this result, you can easily and quickly find out whether the tube is ok or not. (You obviously don’t need your nozzle for this test)

Regarding the new nozzle, he probably bought the wrong type, but buy, to start with, a 100 Watt ø18mm lense, then you can start testing and adjusting the machine. By the way, I also have the old/original type nozzle for my 60 Watt machine and it works just fine.

Ok, i saw something on here showing that test. Im waiting on an order of glycerin as we are still experiencing freezing here. Hopefully 8ll get to it Sunday.

I think dirty is an understatement… it’s got a hole in it… ![]()

The bench head appears to be sans a mirror… If that’s the case I’d assume it’s the new head. It should have a larger mirror for the larger head/lens assembly.

Maybe you can explain to me what advantage you are expecting by replacing the current head with this new one?

When you increase the mass of the head on a standard type of gantry laser, you increase it on both the X and Y axes. If the machine is anywhere in the ballpark of setup, I would think you will have to lower the acceleration speeds, at minimum… I.E. slow the machine down.

I’ve done this enough on my machine to think I have a pretty good handle on what’s happening. I hope…

Also is the matter of the mirrors… keep in mind an 18mm mirror is only 18mm in one axes. When the tube or beam looks at it, it will see 18mm along one axes but on 18mm * sin(45) or about 12.7mm. You’ve lost almost 1/3 of the available mirror by tilting it 45 deg.

You would need to know the size of your output beam to compute this, but if it’s 8mm, like some large tubes, it will expand at about 3milirads/meter or about 3mm after 1 meter of distance or be at 12mm. Leaving you 12.7 - 12 or about .7/2 (two sides) or about 0.35mm on each side of the beam… alignment must take these limits into consideration.

Of course a 6mm beam will be 9mm, leaving only 12.7 - 9 = 3.7mm or 1.85mm on each side of the beam.

Of course a 25mm lens will be of absolutely no advantage with an 8mm beam, since a 12.7mm beam is the largest that can get through the system with the best possible alignment.

I agree with @bernd.dk in that you should check your beam at m1 for the resonance state of the tube. That will tell you if you can make it work.

This is the wiki for transverse electromagnetic mode (TEM) or resonance. I lost my bookmarks, but this wiki explains it pretty well, it also has a section on lasers and how it’s applied.

If that lens was in the machine when he did your example, it’s no wonder it looks like it does.

I don’t remember the dielectric effect on water with glycerin, went through this before. Ended up using one of the food grade variation of propylene glycol. I live in a little town, one grocery store and one dollar store, got it at the local feed store.

It slowed the coolant flow by 50%. The additive also created massive amounts of bubbles in the coolant… Here’s a video of mine…

I purchased some laser coolant from Cloud Ray, been running with it ever since… sorry I don’t have the link…

I have replaced the head on mine. Most of these parts are not generally a bolt on. I had taken the head off of mine and found holes didn’t line up… Russ sent me a dxf file of an adjustment. So I had to put the old head back on and cut the new part out… That same day a small package arrived from the UK, Russ had send me one… great guy…

Unless you bought it from whomever built your machine, it might not fit quite right. If it’s off in the Z axes, you can’t adjust that on these heads…

It might not be like changing the house air filter…

Good luck

![]()