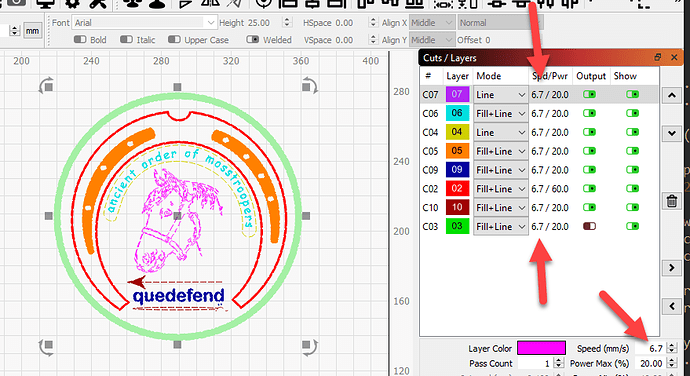

Can anyone help please. This image is taking 4 to 5 hours but I’ve seen others here that take less than half an hour. Here is a image and file. If someone can look at it for me pleas

Mosstrooper2.lbrn (1.9 MB) e I would be very grateful.You have every layer set to 6.7mm/s (roughly 0.25 inches/s) which is very slow.

Don’t know what kind of laser you have but you will likely need to also increase the power to go with the speed increase.

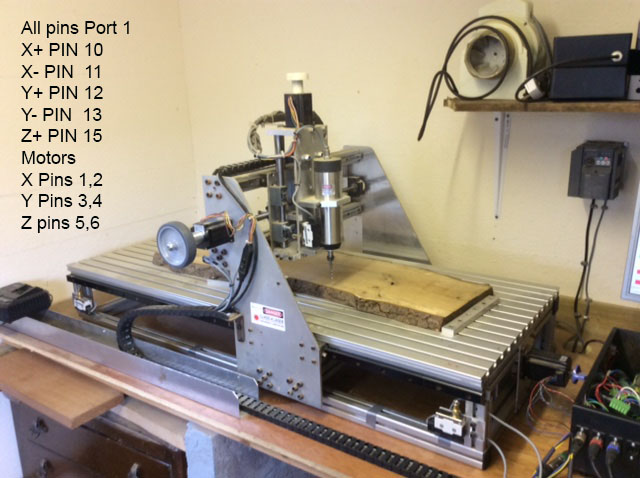

Thanks Adam, As you can guess I’m very new to Lightburn. I’m using an Endurance Lase 10W+ with my homemade Router that I have been operating for many years using Aspire. I use Mach4 so I have to us GRBL3 code and modify a few lines to get it to work. So I set 400mm/sec and 45% laser power.

Geroge

The laser you have is probably fine. Though you are never going to go particularly fast on a machine like that. You may have set it to 400mm/s but it’ll never go that fast - at least that’s my guess.

Run the command $$ at the console and check $110 and $111 - those are your max feed rates in mm/min (so multiply by 60 for mm/s).

Without the fear of appearing foolish Adam, Where do I find the consol to type in $$

I’m pretty sure my machine will go pretty fast.

Click on the Window menu at the top and then select “Console” if it’s not already checked. It’ll be one of the tabbed panels on the right side of the UI.

Also can go to Edit > Machine Settings and look for Max Feed Rate in there (you may have to expand some sections)

Typing $$ in console gives no results,

Console says

Waiting for connection…

File imported in 74 milliseconds

You need to make sure you are connected to the machine first. If it says “waiting for connection” then you aren’t connected. Try selecting the specific serial port your machine shows up on for your system.

Ah that’s the issue, I’m not connected to a machine, I just use lightburn to generate and save the Gcode via GRBL3 that I load in to my Mach4 setup…

I’m seriously considering buying anther machine like an A3 Pro 2500mW Laser Cutting Engraving Machine Eleksmaker Laser Cutter and leaving my main mahine to wood carving duties.

You won’t have a console connection, because you don’t have a controller that LightBurn can talk to. Depending on the max speed of your machine you can likely go faster, but lasers on CNC machines are slow - think about it: you now have a tool with a stepover of 0.3mm. ![]()

Because your stepover is large and the speed is slow, you could likely get away with using Flood Fill for this, though it might work better to just put everything that’s filled on the same layer - you’re using identical speed and power for all of it, so you have a lot of unnecessary extra travel happening.

In Edit > Device Settings, enabling ‘Fast Whitespace’ and giving it a faster speed there will help too.

Thanks Oz, I only put things on different layers to assist me in the drawing. Makes sense now to put them all back on the same layer.

I’m seriously considering purchasing an Eleksmaker control board and turning my machine into dual purpose. All I need do is plug my existing steppers into the new controller and hopefully I’ll be more suited to laser work. Have you any advice for me on a suitable board that will talk to Lightburn and give me the rastering I’m looking for.

The board isn’t the limit - the machine is, because it’s carrying the weight of the spindle and gantry. Lasers are usually very lightweight, so they accelerate quickly, and they’re usually belt driven instead of using lead screws, so they can move fast as well.

If you plan to do photo engraving, I’d recommend a 32-bit controller, like a Cohesion3D or Mini Gerbil board, because they’ll process the GCode much faster, but you’ll likely still find that the physical weight of the machine is your biggest limiting factor.

Hmmm, I didn’t think it was that heavy, well built but not weighing a ton. I was thanking of the Mana Se V3.1 Control board. as long as Lightburn will talk to that direct and produce the PWM for my Endurance laser then fine. For under £30 it’s got to be worth a go. Problem is I don’t see the Mana Se in the machine drop down menu so I assume it uses one of the GRBL formats. If I connect it and use find my machine will that work.

Sorry to be a pain, but if I don’t ask I usually end up kicking myself.

George

Your machine is driven by leadscrews, and even just the carriage with the spindle and Z motor likely weighs 15 lbs. By comparison, the weight of the mirror / lens carrier and belts for a laser would normally be measured in ounces or even grams.

Cheers Oz, Looks like I need to get myself a new ultra lightweight machine, Ah well it’s a learning curve! I suppose.

I have appreciated your feedback.

Regards

George

Yes you can choose GBRL3 format and it usually works but it will be slow on CNC machines. You can pickup a cheap K40 CO2 laser on eBay and they work fine after some tinkering with belt tension and mirror alignment.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.