BACKGROUND I have a heavily modified K40, the only thing original in it is the power supply.

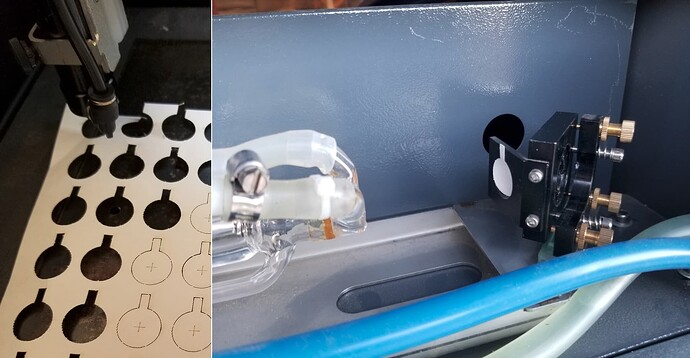

I have a CR35 (“40W” Cloudray Tube), running a Mini Gerbil 3 controller and a full custom build gantry/mirror system.

Been using this setup for around 2 years now, and been operating great. I replaced the tube around 2 years ago when I rebuilt the entire unit and swapped to the mini gerbil 3. Again, been operating perfect for around 2 years.

I run a CW5200 chiller all the time, and operate between 15-17 degrees Celcius at all times.

I run LightBurn, and my settings at 35% power is 8mA and 40% power is 9mA, of which I have an analog ammeter to measure this.

Ambient temperatures from less than 10 degrees ambient temperature up to 30+ degrees celcius in the garage.

ISSUE

About a month ago, I suddenly had a loss of power, where I would normally get the 8mA & 9mA at 35-40% respectively, it dropped down to maybe 6-7mA and I had a weird ‘noise’ coming from the power supply, like a buzzing. I couldn’t smell anything, but decided to replace it anyway with a brand new Cloudray M40 power supply.

The tube is still pink/purple, everything is clean & aligned, but the power drop off had me thinking it was a power supply issue rather than anything else. I can crank the power up in Lightburn and I will then get higher current too.

So I swapped over to the new power supply, and had NO change, still the weird noise from the power supply, still low amperage. Couldn’t figure it out, so realised well it’s not the power supply so reverted back to the original one again.

I flushed my water (distilled) and still no change either, figured there was a current leak.

Left it a few days, tried again to trouble shoot a few days later and it was working suddenly!

35% went back to around 8mA and 40% went to 9mA.

Been fine the past few weeks then again today - loss of power. 35% is down to around 6mA and 7mA for 40%!

Can’t figure it out, if it’s a faulty tube, why is it still purple? I’m not getting any arcing, but just seem to have a similar noise from the power supply again.

Not sure how to troubleshoot? How do I tell if the signal / PWM / controller board isn’t the issue? I don’t have any replacements for these and ideally would like to troubleshoot without replacing…

Any ideas what can actually cause the loss of current?