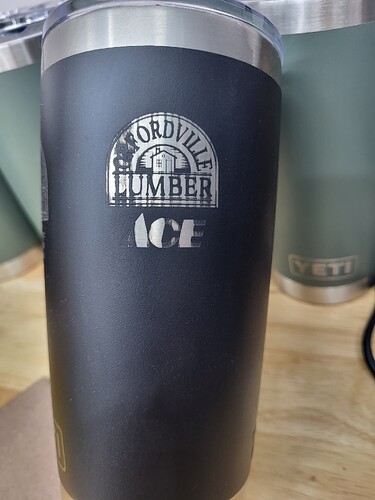

Using a Laguna EX Co2 150 watt laser. stationary Fill Settings at 300 mm/sec 25% Power, 0.073 line spacing, 357 lpi

using a 2.5" lens. cleaned, aligned. Approximating the distance from mug at 3/4"

Are you using a Y axis roller or a Y axis chuck?

You are getting incomplete burn through on the powder coat. Slow down the laser or make the laser hotter (probably a combo of both for best results)

No I’m not. I usually build a quick corrugated jig and place mugs in.

I keep the image size small enough to not “wrap or warp”

The thing I’ve noticed about Yeti tumblers is that they don’t have a super consistent thickness to the powder coat. I’ve seen this “banding” on some of mine and it might have something to do with how the powder was applied. As JimNM mentioned, turning up the power or slowing down the speed may help it cut through this more consistently.

Thanks all for the feedback. Will try slower and more power.

A 2.5" lens has a spot of about 0.2279mm. Meaning your interval is a bit tight as the best interval you can depend on is ~110dpi. The 0.073mm interval you picked is about 3 times the resolution of what your lens can actually accomplish.

I’d suggest you watch this video by Laser Everything on photo engraving. I realize you are not doing photos but the video has excellent graphics to explain how to pick the best interval for any laser and any material. You will use this information the rest of your life with a laser… well worth the watch.

If you’ve taken this into consideration, then I’ll move on.

It has to be focused as close to the material center relative to the available depth of field for that lens, which is pretty wide. The depth of field for a 2.5" lens is almost 3mm. You need to keep the material within that range…

Many of us de-focus the beam, but it being a variable distance, it might be a problem for you. I’d also suggest a slower speed, if possible.

Is this your first mug?

Good luck

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.