grbl 1.1F on a MEGA 4 axis board x,y,z,a

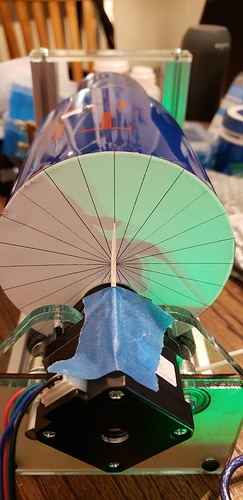

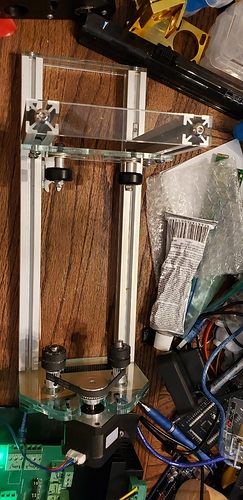

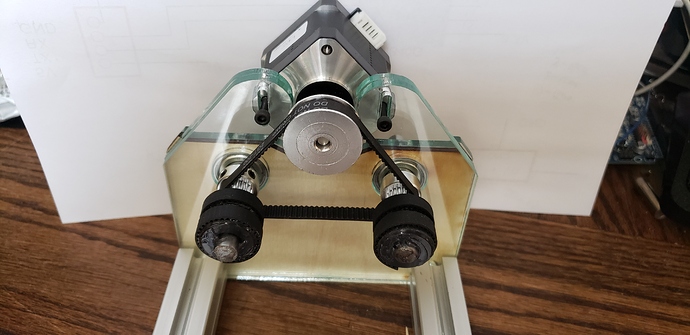

i have a DIY rotary with TB6600 driver with 32 microsteps (6400) @ 1.7A - see attached pics of roller

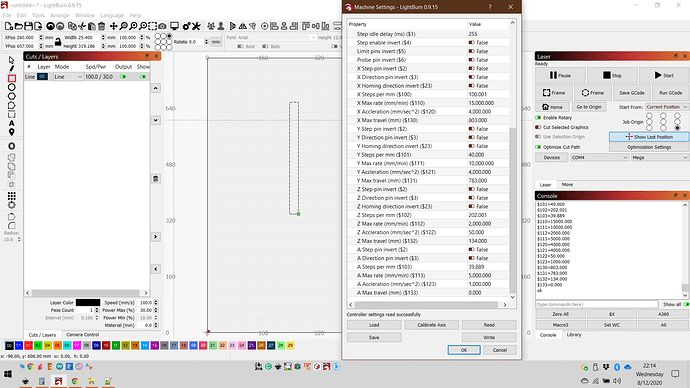

doing math as described in the online documentation, the steps are short… could be part of my misunderstanding with other settings

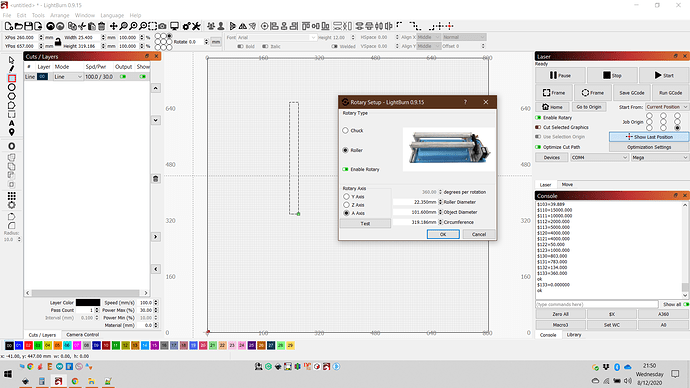

i enter the settings in rotary setup as needed - see attached

my rollers are 22.35mm (smaller rollers - outside dimension with rubber grip glued on)

using tumbler for testing 101.6 diameter measured with caliper( go figure it measured exact)

auto circumference 319.186mm

i adjusted the $103 setting to get a complete 360 spin on tumbler for test, pretty exact

my $103=39.889 - see attached for settings

when i make a square design at X=25.4 Y=319.186

using current position @ lower right corner

the axis rotates ~4 1/2 turns

am i entering wrong info somehow/somewhere???

the gcode file output: notice the A dimension of 1636.511 ???

G00 G17 G40 G21 G54

G91

M4

; Cut @ 100 mm/sec, 30% power

M8

G0X0A0

; Layer Line

G1A1636.511S300F30762.8

G1X-25.4F6000

G1A-1636.511F30762.8

G1X25.4F6000

M9

G1S0

M5

; return to starting pos

G0 X0A0

M2