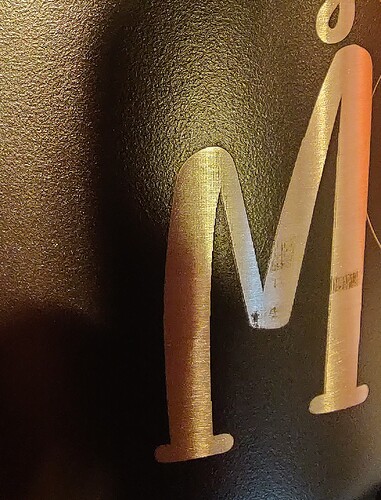

I know most people laser engrave tumblers with CO2 lasers and I may eventually make the jump to one of those to save time on engravings, but for now I have a low power (4.2W JTech) diode laser. I have engraved some tumblers with it that turned out pretty good after cleaning them a good bit, but sometimes I get leftover lines where I am guessing the powder coating didn’t get removed all the way. I was wondering if anyone knows how I can help reduce this in the future whether it is by reducing speed, better cleaning method (mine now is La’s Totally Awesome Cleaner and magic eraser), or lower line interval? Right now I am doing 450mm/min (slow I know but has worked on some cups) 100% power, fill mode, bi-directional fill, cross-hatch, line interval of 0.08mm, 1 pass at a 0 degree angle. I am just trying to get the fill to be as silver as possible so trying to get out all of the powder coating as I can. But any information or help is greatly appreciated. I have attached a picture of a recent black powder coated tumbler where a couple of the letters have the issue but other parts of the cup is fine.

It is just an issue of being under powered. There’s not much to suggest beyond what you have already tried.

Yeah I figured it may be. I’m trying it now with 2 passes. I guess the ones it’s worked fine for so far may have just had a thinner layer of powder coating on it.

Yes, many tumblers have inconsistent coatings on them.

Try this product from Dollar Tree

It’s worked well for us in cleaning sticky residue and best of all can’t beat the price

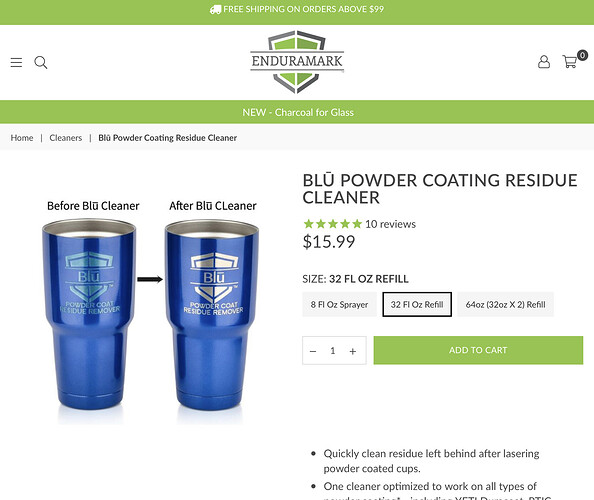

There is also this product

Good Luck & Cheers

Sasquatch

Thanks I will give those a try!

I am using a 60 watt CO2 laser at 30 percent and 40 percent power. the 30 I did two passes. both leave grey behind inside the fill area. the lines engrave great. just the fill area is not clean.

I you go here and look down the page about 75% you will see all 4 lasers and specs. I believe if you use the focal spot size (.05, .06, etc) of that laser you will engrave more powder coating off and get that stainless steel look (after you clean the engraving). Depending on the laser you have.

Wipe it off with some acetone. ![]()