I have a eleksmaker laser that has been on the shelf for years. I’m trying to get it working with a new makerbase dlc32 v2.1 board. The x and y axis work perfectly and smooth but the laser will not function in LightBurn. The wiring on the Makerbase board is S,TTL,VLN. The wiring on the Elecks laser head is PWM, (-), (+). Does anyone know why when I hook it up in that configuration Lightburn loses connection and it seems no power is getting to the laser head. Do I have to change the pins to something else?

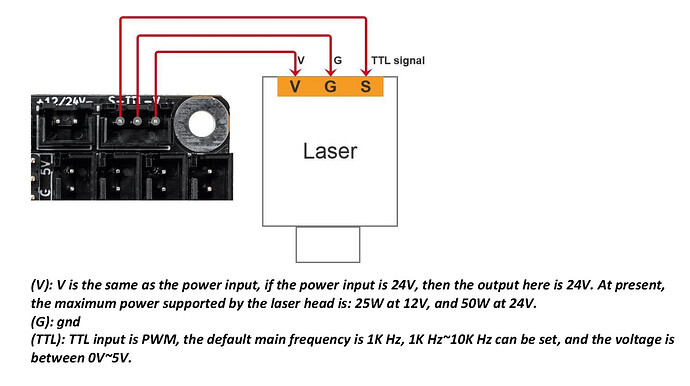

The signal out is ttl compatible… Center is ground, S is the ttl pwm output and V is supply voltage.

MKS-DLC32-Manual.pdf.txt (2.0 MB)

![]()

so are you saying

maker board laser

S----------------------PWM

TTL-------------------(-)

VLN-------------------(+)

Yep… ![]()

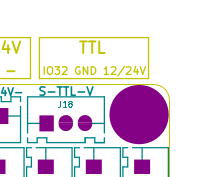

Both of these came from the manual… IO32 is the pwm or signal output.

![]()

I did that but the laser wouldn’t fire

Was it always this way or did you mis-wire it originally?

Swapping this by mistake may cause issues… with the laser module and/or control board.

Do you have a voltmeter? You can check the pwm going to the laser module by simply measuring the pwm signal. A voltmeter will read rms voltage, so at 50% you should read 2.5V, 20% 1V and 100% 5V.

Make sense?

![]()

I must have screwed up this board. I tried both boards with interesting results.

elek board

20% = 1.5v

50% = 2.4v

60% = 2.3v

70% = 2.0v

80% = 1.5v

90% = .8v

100% = 0v

That explains why this eleks board isn’t working correctly, must be something in the set-up

Makerboard is 0 voltage at every setting

OK I received new maker base motherboard and new diode laser head 20watt. I checked the laser signal and it is scaling correctly,0-5vdc. I have a few problems to solve before this is a usable laser.

I installed simple end switches but they are not working correctly, simple open shut. They have 3 wire connections. Before I do anything stupid I wanted to check here first. Is it just the grn

d/signal connections I should be worried about?

Second problem is the laser will engrave a square were it sits on the bed, but if I move that square to another location, with in LightBurn, it will just burn in the same spot as before? what am I missing?

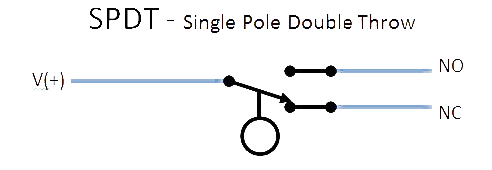

Most machines are low active meaning you need to go to ground. Unless it’s a powered switch, they have probably made them to be used as either pull up or pull down switches.

There are Normally Open (NO) and Normally Closed (NC) type switches. One line of the three is common. Most of todays switches will take into account the two states.

I’d suggest you check the start from option in the laser window. It sounds like you want absolute coordinates.

![]()

so it sounds like I want

norm open

S-----------------I I--------------grnd

and use the absolute coordinates .

any idea why laser will engrave a square were it sits on the bed, but if I move that square to another location, with in LightBurn, it will just burn in the same spot as before?

If you use absolute coordinates it should engrave where it is on your workspace. With any other engraving/cut it will engrave at the user/current position, relative to the job origin.

Re-read this…

![]()

This topic was automatically closed after 30 days. New replies are no longer allowed.