Have sculptfun s6 and lightburn New user. I made a spoil board grid to match the S6. I want to use x200 y200 as my home. When I tell the laser to goto this setting it ends up at x240y240 how do i set rthe home to this. (no limit switched)

There may be a terminology gap that needs to get sorted and then I should be able to help.

Home in LightBurn terms is where the machine homes to during a homing cycle. Without limit switches this is obviously not what you want to do.

I think 200,200 is roughly the center of your machine bed.

Can you describe how you plan to use the laser so that you’d want a reference at 200,200? That will determine how best to answer your question.

Continuing the discussion from Home position without limit switches:

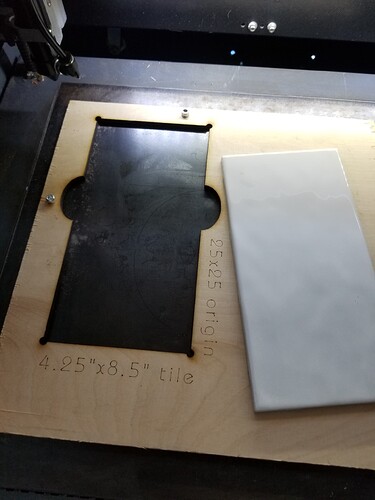

The spoil board was cut on a cnc router and sits within the frame of my S6 scupltfun and exactly matches the graduations on the machine. I thought this would allow me to position of say a coaster which I cut on the CNC Vetric Mach3 by usibg the grid .

Looking at the S 6 there is no way I can move it to X0Y0 as it crashes into the machine. Perhaps I am looking at it like a CNC mach 3 where I can allways cut to the limit of the board.

If I try to move the laser to x0y0 if falls well short of the target. setting a home point without limit swithches escapes me.

I am located in a retirement village any many jobs are one off, with the exception of coasters.

In CNC I set my start position at the LH corner of my job with Z set at zero at the top of my project.

The more i read the more confused i get.

cc

Lightburn and Scultpfun S 6 engraver

Got it… I think there’s a few things going on based on your thorough explanation.

Basically, it sounds like you’re trying to find a reliable way of managing laser coordinates. A few things to understand:

- You’re right that you’re bringing some of your CNC mentality into play. While sharing many of the same principles there are a few key differences with lasering. With CNC you’re often “rehoming” at arbitrary positions meant to ease machining. When you do so much or all of the machine is working in negative coordinates. Lasers generally only wants to work in positive coordinates and that is how LightBurn is built.

- If a machine does not have homing switches then you need an alternative way of “manual homing”. Basically, the position your laser head is when you turn on the laser will be 0,0. All other coordinates are relative from there.

Learn more about working with lasers without homing switches here:

Common Grbl Setups - LightBurn Software Documentation - For your purposes, I suggest you shut-off the laser, move the laser head to the front left of the machine (where you want 0,0 to be) then turn on. If you want to have a precise way of getting repeatability for this then try to find a way of mechanically locating the head at the same position each time or use the laser light to reach a specific point on the bed and rezero the laser by issuing

G92 X0 Y0. - Until you get very familiar with your laser I suggest you work in Absolute Coords. This is set in the Laser window in the “Start From” pulldown.

- If you are working with coasters or other circular items a lot I suggest you review the new feature in LightBurn called “Center Finder” located in the Laser Tools menu item.

How do you ensure the a certain location on the cnc is ‘exactly’ the same position when you move the board to your S6? You need some type of registration to ensure you can move material between machines and exactly position them.

The ‘home’ works on the laser the same as your cnc.

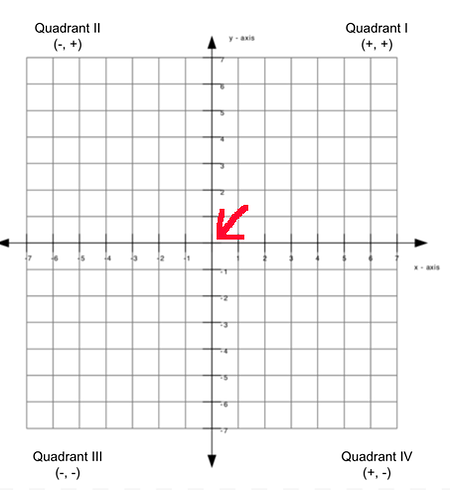

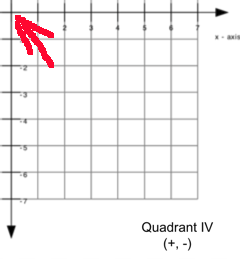

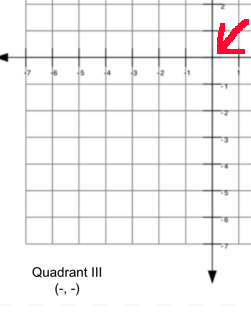

The arrow points to all ‘home’ positions and determines the quadrant you operate within.

Generally considered 0, 0. Maybe different on some machines, but it’s relative to this location.

If your home is rear/left you are in quadrant iv… You can only move to the right and down.

If the home is rear/right, down and left…

Does this make sense?

@berainlb has added some information on how to change how it looks at quadrant movement.

As a general rule, you don’t get to pick the machines ‘home’ position. You can set it up to have an ‘origin’ or the job elsewhere…

As far as alignment, you can also use a template to place the object in to ensure alignment.

Good luck

![]()

Thanks for your help. Home Position set and saved. Now looking at importing images i use in CNC. First effort did not work but will keep trying. Regards David

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.