Unusual question - How can I quickly get a dirty lens (underside, direction towards the nozzle tip) in a standard 80Watt CO2 laser nozzle? The laser is connected to the included small standard air pump and there is noticeable air flow. The laser beam is adjusted and a test shot shows that the beam is in the center of the small exit hole at the end of the nozzle.

So, are there other things that can cause a dirty lens?

I was watching one of Russ Sadler’s videos a while back where he was discussing air assist. One of his tests showed debris getting forced back into the nozzle from blowback ( I think that’s the term) His premise was that we tend to use too much air pressure / flow.

I believe it was this video.

Thanks, Tim

but I’ve ruled out the “vacuum nozzle effect” because there’s almost too little air coming from the small aquarium pump.

My best guess, after humid compressed air, was reflections of the laser beam, but it’s very nicely centered from what I can see from the tests that have been done.

mmmmmm, strange…

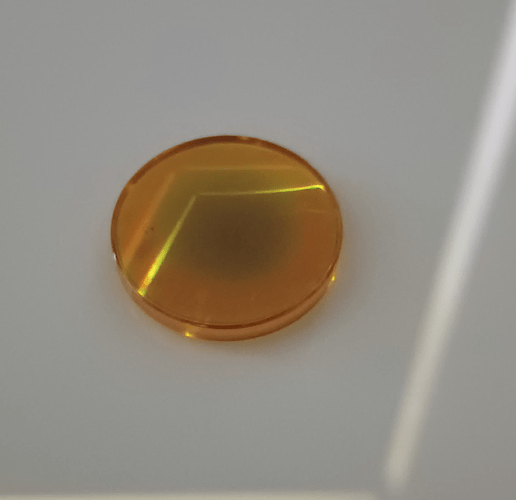

Do you mind posting a photo of the lens… that might help people decide on a course of action.

Unless I’m cutting, the air pressure is very, very low… just enough to protect the lens.

I did a stainless steel label, got a semi OK result, but it cost me a lens, purely from reflection, I believe.

A photo might help if that’s doable?

![]()

If it’s inside the laser cabinet, it’s inhaling fumes and exhaling them directly onto the lens through the assist air tube.

I added a cheesecloth filter:

Which prompted me to drill a hole in the bottom of the cabinet and add a snorkel:

Admittedly, the pump now inhales air from the Basement Shop™, but it’s not nearly so smoky outside the cabinet. ![]()

Hi @ednisley and @jkwilborn , the problem is that I am not physically at my friend’s machine and all communication is done over an internet connection that feels like the Russians have cut the cable…

However, nothing has been done on the machine other than acrylic and very little plywood, in total only a few hours of activity.

We have gone through everything I could think of without result and are now at the stage where my friend checks the location and condition of the lens once again and does some production after an additional round of cleaning.

(it’s the same lens, the light just makes it look like a different type)

The small air pumps that come with most machines do not have an intake filter and it is a very good idea to find out if that could be the problem.

On my own machine I have the original pump, together with an extra external 80l (60l?) pump mounted, it works fine for the light jobs, and if there are very heavy jobs I can switch to a noisy air compressor - with filter and water separator.

I don’t really know why, but even though I have a reasonably continuous production with plywood, MDF/HDF and acrylic on my own machine, my mirrors and lens are very very rarely dirty. But of course I’m not going to complain about that ![]()

Is there actually visible debris when he cleans the lens or is there little improvement? If something wipes off, then it’s external debris being deposited.

I wasted a lens doing a stainless steel plate - reflection … won’t do that again.

Are these 20mm diameter lenses?

After enlarging the center image, you can see a variation of the damage, so it appears like it’s getting hot. Can you physically tell if it’s the side that would be facing the material? That may be a good hint.

Where debris lands is pretty much dependent on machine ventilation. If it moves from the laser to the vent, it won’t end up elsewhere, such as on mirrors.

Probably why you have little trouble with dirty mirrors.

![]()

I engraved a dozen acrylic signs, each about 200×75 mm, about half a millimeter deep:

Which deposited this crud on the machine’s exhaust port:

I cannot judge how much of that would go through the air pump, but it might be enough to foul the lens (and the mirrors, come to think of it).

He says it’s easy to clean the lens, it’s not burning into the surface. I will see tomorrow what the new attempts show.

Thank you for sparring, I will keep you informed.

There are too few production hours for it, he hasn’t started up right yet.

Thanks to you too

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.