I am new at laser engraving and I’ve been doing some test engraving with text. No matter what size I make the text, the line thickness is the same. Is there a way to adjust this in Lightburn?

Are you talking about the outline of the text?

If so, the line thickness is determined by the thickness of the laser and the effect of the burning on the material. The only real way to change line thickness is by changing the optical conditions of the burn and possibly the material to which you’re burning. You could potentially change lens or try different defocusing techniques to change the actual line thickness.

If you’re trying to get as thin a line as possible then focus on these main things:

- get the finest focus you can achieve

- potentially get a lower focal length lens

- use the minimum amount of power necessary to make your mark

- change materials

Yes, I’m trying to make the outline of the text thinner. I’m also having the same issue with a simple box that I drew around the text. I ran the text with two parameters - 100mm/sec speed and 40% power and then 100mm/sec and 20% power and the line thicknesses are the same. Can you tell me how to get the finest focus inside the software?

Maybe I wasn’t clear in my previous post. This is not a software thing. This is something inherent in lasering.

Essentially line operations in LightBurn assume the laser width is infinitely thin. The actual laser dot width is determined by physics. LightBurn isn’t really involved in focus other than potentially triggering an auto-focus request. However, it’s up to the machine itself to provide that capability.

Can you provide details as to the type of machine you have? Does it have auto-focus capability, and if it does, has that been calibrated? If it’s manual focus, how are you focusing the laser?

In any case, I’d suggest running some focus tests. If you have a motorized Z-axis you can use LightBurn’s Focus Test (Laser Tools->Focus Test) to confirm optical focus.

If you have manual focus then a ramp test may be the best approach for confirming focal height.

Thank you for the clarification. I’ll try the focus test and see what I can learn.

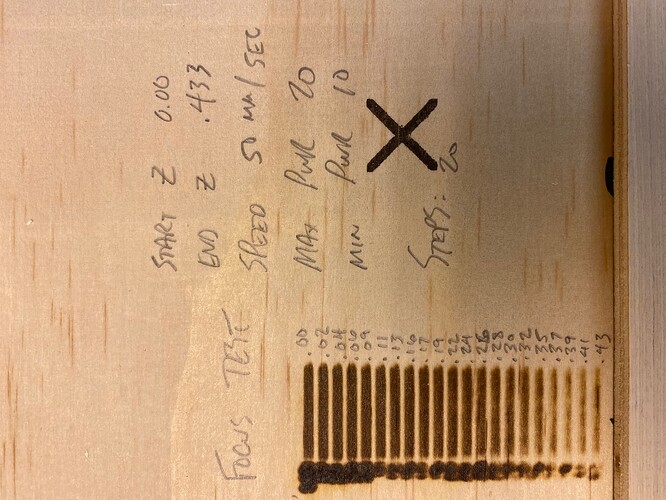

Hi berainlb, I ran a focus test with 20 steps which resulted in a series of lines that got lighter as it went along. The speed was at 50mm/sec, max power was 20 and min power was 10. I’m not sure what the results of the test is telling me. Could you provide some info on this?

After the focus test, I realized that I had the focal length set too far from the material. So I set the length using the gage and the lines were much thinner. I’ll keep tinkering with this. Thanks for your help.

Can you provide a photo of the results?

This is the most fundamental component of keeping in focus. Even small variations will put you out of focus. You should refocus for every basically every job or at least between every material swap.

This was before I changed the focal length. Which is probably why the lines are so thick.

Is that the thickness of line that you’ve been dealing with?

If so, there’s something more fundamentally wrong with your setup.

You should have a very thin line no thicker than about .2mm.

Can you confirm the type of laser you’re working with? You list Ruida as your controller so I assumed this was a CO2 laser. Is that correct? What is the focal distance of your laser lens and how are you focusing the laser currently?

Start with what you think is ideal focus. Then I’d suggest rerunning the focus test at .5mm increments both higher and lower than starting focal distance. This should confirm whether or nor your focus is ideal.

Once you do that, identify the thinnest line, then repeat the focus test but at .1mm increments. Then identify the thinnest line.

Once you’ve done that, you should now know the proper focal distance. At that point you could create a new gauge that matches that distance or come up with some other method of getting to that ideal distance.

The lines are much thinner now that I changed the focal length, which according to the gage is 15mm But I had set the focal length using the long side of the gage, which measures 41mm. I’ll call that a rookie mistake. Should I run another focal test with the correct focal length?

My engraver is a China brand - Tounjen.

The gauge is a start but there are small variation between machines that require fine tuning. I’d encourage to run the tests I described to narrow in your focus.

I ran another focus test and have adjusted the focal length and the width of the line is now satisfactory. I’ll keep everything the way it is for now and see how my first real project goes. I really appreciate everyone’s help with this. This forum is very helpful.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.