Hello LB community,

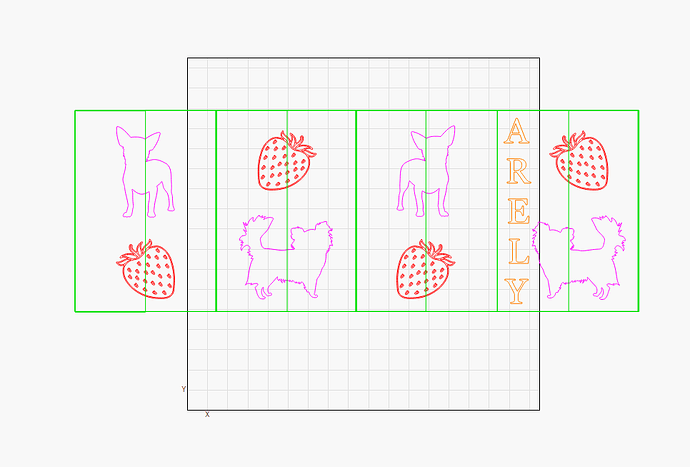

I have had my laser, Omtech 50W (175x175mm) with a factory rotary tool, for several months now. I have learned through trial and error how to get the laser to work the best on different tumblers. I have made plenty of Fudge-cups, but I have learned. The one thing I still understand is how to create a tumbler wrap with the rotary tool. I have made a template, but the LB won’t run it. What am I doing wrong? I have disabled the “ignore out-of-bounds shapes if possible” and my template is only 240 mm wide which is small enough to fit the 280 mm circumference. Any suggestions would be greatly appreciated. Thanks! ![]()

These never operate well when you exceed the defined work area…

Work area being 175mm and your graphic is 240mm… Just how far out of the work area do you consider fair ground and should be ignored by the controller?

Since the fiber is handled a bit little different, we’d have to ask one of the Lightburn people if this is an issue can be overcome.

Maybe @JohnJohn has a better answer or a fix, for your delima. Hang in there and we’ll see what he comes up with.

Sorry I can’t be more specific… Does your preview show anything?

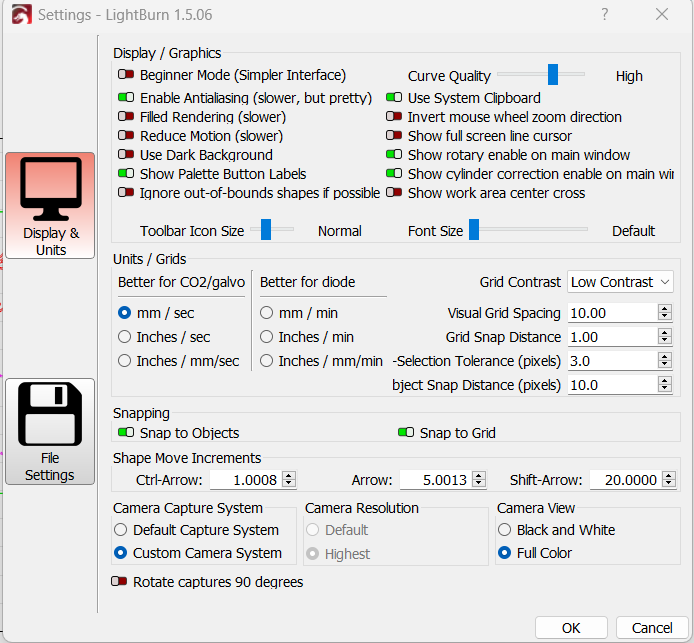

![]()

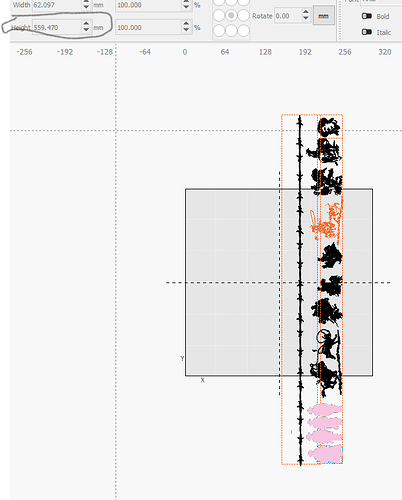

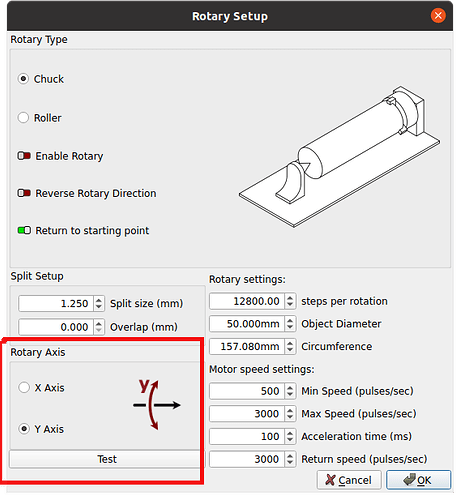

Do you have the rotary set up to roll on the X axis, or the Y axis? My roller is on the Y and I have to turn the object 90 degrees to get it on the tumbler in the correct orientation.

IOW, press the comma key “,” to turn the engraving sideways.

I don’t think it’s the size, I have run full wrap well off the edge of the work area. Something else is going on. Without looking at your file, you could try a test grouping everything blue, and just frame the blue layer. Or red.

I ran this around a 7" diameter teapot, matched up the ends of the barbwire.

Good to know this does work… however it does kind of violate the basic operation of these.

I have not had this issue, the co2 has a large enough work area as does the fiber. So I commonly don’t do this…

I’ve seen lots of aggravation from this … probably why they have the ignore option…

We know the rotary is handled a bit different on a fiber… so I’m curious…

![]()

How so? Just curious.

What possible purpose could a defined work area have if you can drive over it? The main purpose is to define the machines safe operating limits.

How big is the rotation axes on your machine?

![]()

This sounds possible. I will give it a try and let you know if it does, thanks Al.

IIRC, when Ignore out of bounds shapes is turned off, the machine will blithely ignore the limits and, in the usual XY case, smash into the rails.

With a rotary, there are no limits: it just keeps turning until it reaches the end of the shape, with no harm done.

Whether the result by double- or triple-engraving beyond the full circumference on both sides looks good, that’s an entirely different matter.

There are limits… there is no infinite axes on these. Once the steps have rolled over, the machine is lost.

![]()

A 175 mm X axis has only 14 k steps at 12 µm/step, so the numeric limits are way far out to the sides with a 32-bit controller.

I zoomed out as far as LightBurn would let me, then dragged the workspace 3 km (!) to the left before my arm got tired: plenty of room in there.

Now, whether the controller will ignore the maximum X travel in rotary mode is another question entirely, about which you know far more than me.

Just saying it isn’t infinite.

![]()

The problem is that he is trying to use a Y AXIS roller and his X AXIS is larger than the machine can move.

He is not using an X AXIS roller…

On these galvos you can select which axes you’re rotating about.

I mount mine so it rotates like in the setup above. But you can mount it vertically and select X as the rotational axes. It’s easy to change how the rotary is mounted, unlike a gantry co2.

![]()

Had to jack it up 3-4" to clear the spout. Had about 70-80mm left on the 800mm tower, 300x300 F420 lens, so well within design parameters!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.