Hi, how does one analyze their power supply?

Forgive me for this general open question. I’m still trying to learn about diode lasers and their quirks. I’ve searched the internet for days for a way to check if my power supply is fast enough and strong enough. So I decided to ask a question here. I would like to know if there are tests/procedures that people in this forum have used to check power supplies?

I kinda new to electronics of the laser unit. I have a two tree 20w (not optical) laser w stock driver and a power supply from an Ender 3 pro 3d printer on my machine. I’m using a mks dlc32 v2 board and Lightburn to run the laser.

Just trying learn something for the future.

Take each part of your laser and find out how much current is used in each… Such as the controller the basic motors, the led and anything else you need to power. Add them up.

Check that your supply of capable of this value…

Usually you start seeing issues because of power, such as the controller resetting…

The other option is to measure the output of the supply when the machine runs in a mode that draws the most current. If the voltage drops, it under powered.

Make sense?

![]()

Thank you for your reply. I’ll be working on that advice soon!

Also may I inquire that I’ve read somewhere that the power supply may not be able to keep up with the lasers speed of burning the dot and for the life me I can only figure that means if the laser fires the power supply may not be able to “charge or build” enough power to accurately burn the next dot. Now forgive if these terms are a bit lacking in expertise, I’m still pretty raw in my education.

Thank you for you hard work and time

There are short duration power draws from the laser and motors. If you run your laser at 100%, that should provide a good check point for your power supply voltage at max steady state load. For dynamic response of your power supply you’d need to have the laser running at about 50% (50% duty cycle) and measure the power supply voltage with the meter set to “AC” (or have a large capacitor in-line with one of the meter leads). This gives a rough estimation of the power supplies ripple voltage.

An oscilloscope is an ideal tool for all this, but not everyone has one ![]()

Well I’ve purchased one recently buts just a kit cheapie. I used it to check the PWM hertz. But I’m no expert with it.

Place it on your power supply leads, you’ll be able to see how far the voltage drops during the switching actions of the motors and laser (down to the microsecond duration dropouts hopefully).

Sweet, thanks guys

It might help for some to know that laser diodes rely on current rather than voltage .

That said the voltage must not drop below a certain point to be able to supply the current required.

The makers/sellers of these diode modules seem to like the confusion that they exploit to make things sound more powerful than the reality. For my part I tripled the wire size from power supply to laser head and noticed an improvement in cutting ability . This matters more with higher power diode modules .

My experience is with cheaper ,open frame kit type systems where all the false and misleading claims are made .

I have found 10w (80w claimed)will cut 10mm pine 1 pass 100/100

5w (40 claimed) 3 passes 100/100 .

All wood is tinder dry.

My 10w (80w) draws 3.77 amps at 12.4 volts when on max power . It cuts very well but the numbers do not relate yet I am very happy with its ability to do what I want from it .

If I lower the voltage the current draw increases and vice versa . (I have a variable lab supply)

We will see 50w optical diode arrays in the near future as the price gets better and better as our hobby catches on to more of us .

If your power supply is overloaded you will notice that the fan speed lags when 100% power is drawn .

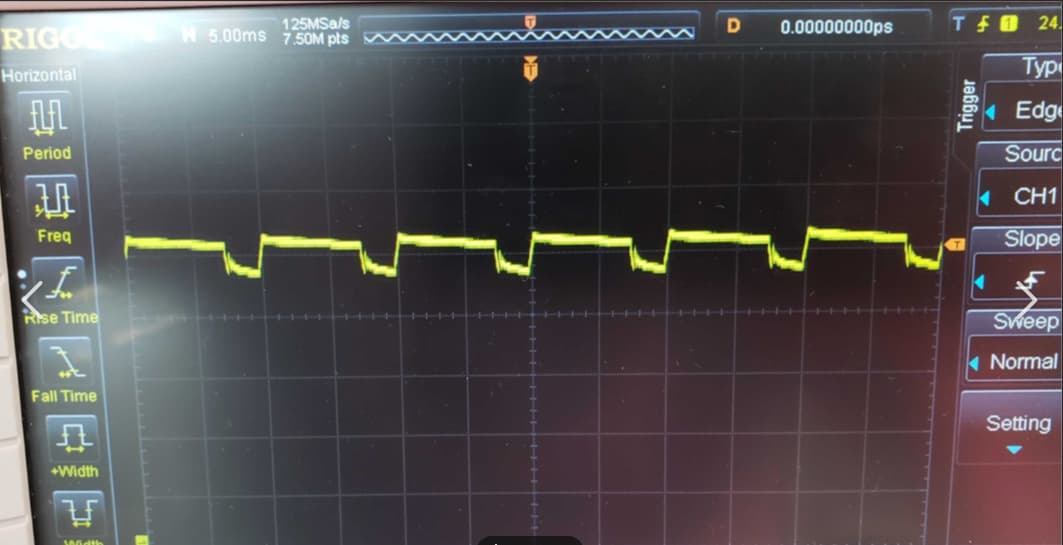

Jerry,

you are looking for something that will look like this

You can see the droops and if you “zoom in” (switch to a higher sweep period) you might be able to see steeper drop spikes.

Cheap power supplies will have poorer transient recovery. As stated above, if the drops are too much or too long in duration, the controller may crash or other obvious symptoms might occur.

That info is amazing and exactly what I’m trying to find out. Thank you. I will update as soon as I can get it done!

Well folks on my fluke meter the voltage stays perfectly stable. But my o-scope took a dump and I must wait for a new one. That you all for your help!!

Ideally the laser power supply should be a separate unit With voltage and current on display. As these diode units build up hours this info will be important to monitor . We are in new territory here . Where real figures are manipulated by sales pressures.

I agree fully Lizzard, I’d like to see the controller source isolated from the laser and motors (common ground or better, Opto-isolation). Having an “hours” meter would be awesome. Seems LB software could also keep track of the laser “on” time somehow.