Hi, I make a wooden wine holder and I need to change the dimensions for the whole plan of the holder. Well, I need to reduce it by about 20 percent. Does anyone have any best practices on how to do this in LightBurn to make it accurate?

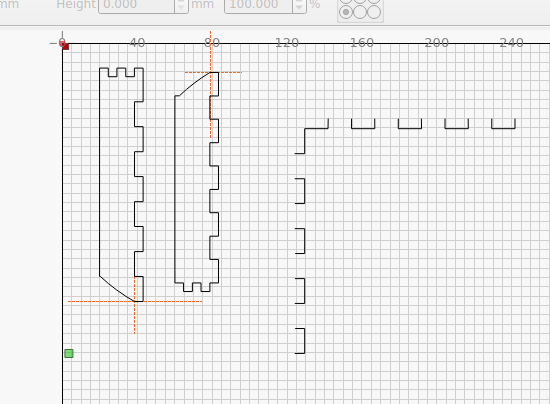

If these are a ‘finger’ type or have specific size notches or holes to put parts together it could be a problem.

This was worded so badly, I’ll try and illustrate…

I built a stereo cover that was generated by box.py site. It’s figers are based on the thickness of the material.

It’s larger than my machine, designed symmetrically so I can cut each corner separately.

I cannot just make it 20% smaller, the ‘notches’ won’t fit anymore…

Make sense?

Good luck

![]()

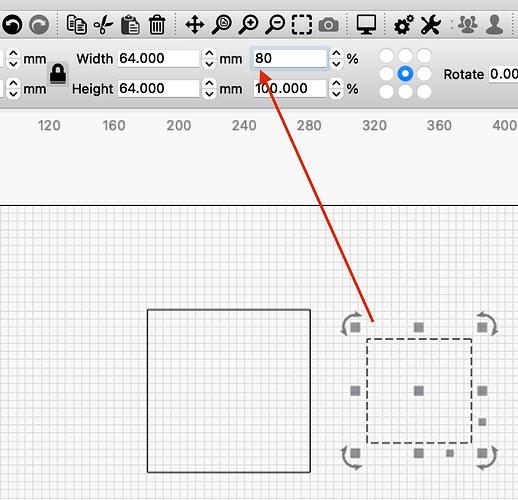

I sometimes scale 4mm boxes with finger joints down to 3mm, with the even numbers it goes very well, 75% and you are down to just 3mm ![]()

(4 mm and 3 mm material thickness)

I could see that. What I was referring is to the same size material used to make a smaller box…

Different paths… ![]()

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.