I have a co2 laser and diode laser setup. I see I can open two instances of lightburn at once and connect to both lasers but can only send one at a time. Is there a way to send both or a similar software anyone is using for the diode? I like the drag and drop and used to lightburn now. I really didnt want to use the software the twotrees provided for the diode laser.

What’s preventing you from sending to both at the same time? This should work in principle.

You don’t list your OS or other relevant information in your profile. LaserGRBL is a very common laser control software but is Windows only. It only controls the laser and offers no drawing tools, however.

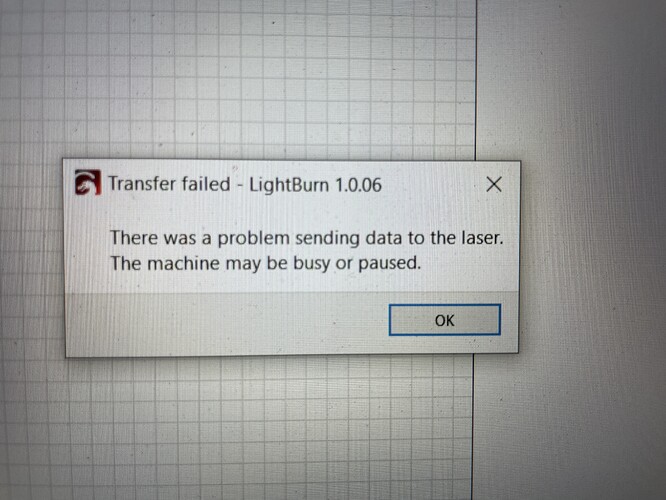

It gives me an error when I try to send both at same time. In a few hours I can try again and report the exact error. I figured it could only send info to one at a time because the error.

Sorry Im using windows 10 on a laptop. The diode laser is an Atomstack X7pro i purchased for wood as the co2 wasnt cutting so great (heavy burns) and didnt cut as fine as the diode is. I was hoping for engraving plastic but it seems to bulge the edges on cuts there. It came with LaserGRBL but first thing I noticed was it wasnt drag and drop and figured it wouldnt be as good as lightburn anyway so didnt play anymore with it.

Ideally you’d get a screenshot of the error as well as full screenshots of each instance of LightBurn being run.

This is surprising. Even a 40W CO2 should cut wood better than the Atomstack. While I wouldn’t be surprised with a diode having a finer dot size for engraving I would be surprised if it cut with a finer kerf after it got done cutting through wood.

In what way is it not drag and drop? I just confirmed that I could drag and drop an image file onto LaserGRBL for burning.

I’ll get this for sure. I have a dr appointment in a little while so when Im back.

i have a 90w laser. I was doing really close cuts for what my wife wanted for ornaments and it was burning way to much. played with it with multiple cuts at faster speeds, slower speeds, higher power, lower power. All burned too close. I confirmed with the atomstack last night the cuts were very clean and the air assist from atomstack is way better then the co2 setup. Ill be buying another from them to use on the co2 now.

Now that Im thinking about it, I only tried to drag an svg as thats what i typically use. I didnt try an image yet.It didnt allow and drag and drop with svg for sure.

You CO2 is not setup properly. The ‘dot’ size of most CO2 is around 0.1mm.

If you are cutting ‘ornaments’ that are 1/2" plywood… what thickness is the actual material…? Sounds like you’re trying to drive a tack with a sledge hammer.

![]()

What do you mean by close here? As in many fine details? You may want to create a separate Topic on potential cutting issues with the CO2 laser. I suspect you may be dealing with some setup issues hindering performance as the lasers should be largely incomparable in terms of cutting effectiveness.

SVG should also work with drag and drop. But note that LaserGRBL does not have the ability to “fill” SVG shapes. So if you want a filled appearance the SVG needs to include lines that fille the shape.

I know I have a problem with the focus. And part of reason is I normally need to engrave clear plastic out of focus. So the beam hits a bit wider. In focus doesn’t melt the inside section so much and makes marks when my wife uses them. They’re used for cake and cookie decorating and need to be smooth inside.

The amount I have to do I don’t have a z axis to keep moving and adjusting all the time. So it’s as good as I can get for wood without having to switch and setup for plastic right after.

Material is between 3mm and 5mm to plywood cutting. I may have some old photos how bad it was turning out lol. Really bad…

What kind of plastic are you melting, is that with the diode?

I have a 44W China Blue and I can cut 6mm at 85% power, very clean lines… You should be able to cut this like butter and quickly.

Lasing a material is a form of machining and as such the power and speed are critical for good results.

What I mean is, like you have found, it cuts the material at different speeds and power settings. There is a small range of power & speed area within the wide range of cutting, that will give you the best possible cut. I run 60lbs pressure when I cut for most wood/mdf types. However, I didn’t always have air assist at this pressure, it still worked.

![]()

Yeah I definitely need help fine tuning both of these.

Maybe one of site ‘gods’ (@JohnJohn ?) can move this for you…

There are lots of videos out there you can reference. Cutting is not always alignment, focus and clean… You tube is critical and must resonate in TEM0 mode to be most effective. That should be the first item, as your alignment should start there.

![]()

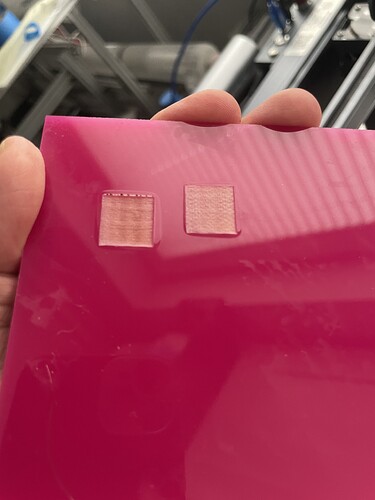

Diode won’t cut with clear. So this I just tried yesterday and you can see the bulging around the engraved square.

It’s still not deep enough but that surrounding won’t work.

For clear and frost using cast acrylic. This pink was of course different and will try to find some other materials.

Your co2 should cut that cleanly and quickly without a bunch of damage.

I think you’re using the wrong tool for the job. ![]()

![]()

Oh co2 will. But not the wood. The diode seems great for wood. But not plastic.

Ideally I keep the co2 set for engraving plastics and cutting and the diode set for wood and colored plastics.

Some days I may have 20+ items to do on the co2 and can’t work on anything else. The co2 is running all day long.

Lol… I’m more primate than deity I assure you, but I’ll do what I can.

The quick tip is if the light passes through the material, it’s not absorbed and the laser won’t cut/engrave it effectively.

It’s counterintuitive to confirm this with infrared and UV so a few folks here have tested materials (safety screens and rarely safety goggles) to confirm that the material interferes with the laser.

This is the clearest and best course of action.

Please feel free to copy and paste a handful of lines from the Console window on each side of the error message. Often the cause of the error can be seen in the surrounding details.

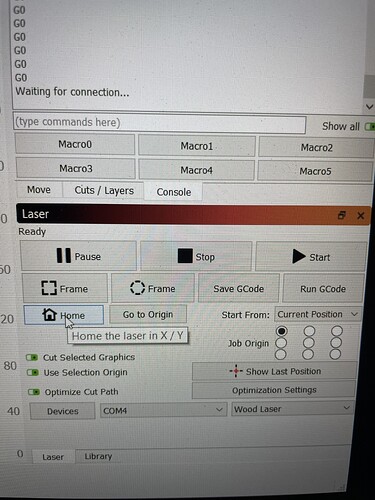

Right now with both open it was giving this error on both. Last time it let me start the diode and gave error on co2.

It says ready but says waiting for connection in console.

If I close one lightburn instance I can use the other.

This is great diagnostic information.

You’re right, as soon as it says ‘Waiting for Connection’ the USB port is disconnected.

Does this (disconnect) behavior happen when you connect with the other laser in the other instance of LightBurn or when you begin to send a large amount of data to the other laser in the other instance?

The lasers aren’t both on COM4 are they?

Are you using a USB hub or any kind of adapters on your setup?

That was it! no adapters. two different direct ports. The “auto” was sending them both to com4 for some reason. it showed com5 at first and somewhere changed. I set them manually and re-added the lasers and now both running at same time

Great!! Glad you’re up and running!

Thank you! Thats one headache out of the way lol. Now to test and focus what the best settings are for this diode…