How to find what the latest firmware is for my ruida controller ? I have a 12 year old 30 watt RF co2 laser with a RDLC320-A controller.

LightBurn tells me that it is running firmware version: RDLC-V5.00.15

I’m coming to this machine having never used it or indeed any other laser cutter before; so am learning on the job. It was working a while back but before the colleagues that were using it gave it to me with a vague warning of “I don’t think it’s working but can’t remember why” !!! So I’m bug hunting unknown problems. Argggh!

The machine originally used proprietary software aps- ethos (the machine is an Apollo 600 made by CAD/CAM technology) and clearly lightburn is wayyy nicer software hence being on this forum as expect to be using it going forwards.

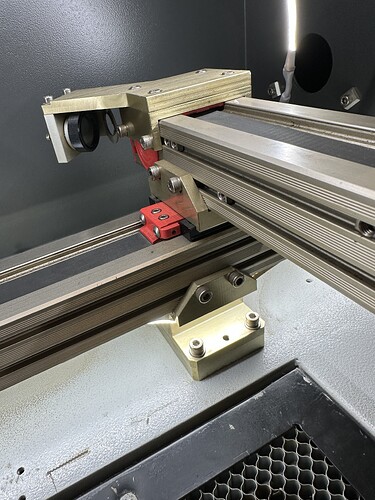

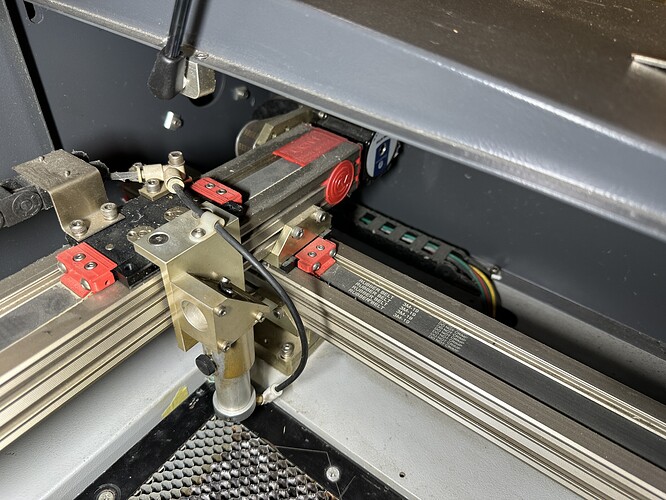

It’s been quite a struggle even getting lightburn and the controller to talk. Annoyingly the machine does not have a ruida control panel so my options are limited. I can’t currently enable Ethernet for instance to try connecting via an IP address, which would be my natural next step. At the moment I can’t get Rd works to connect, but lightburn does.

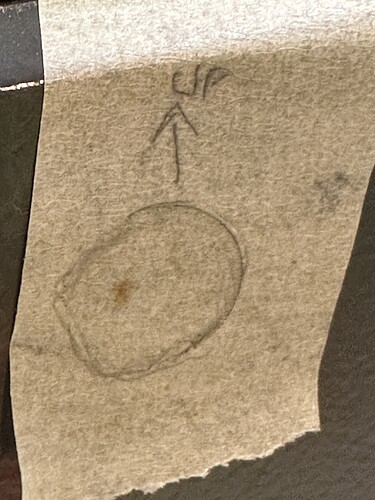

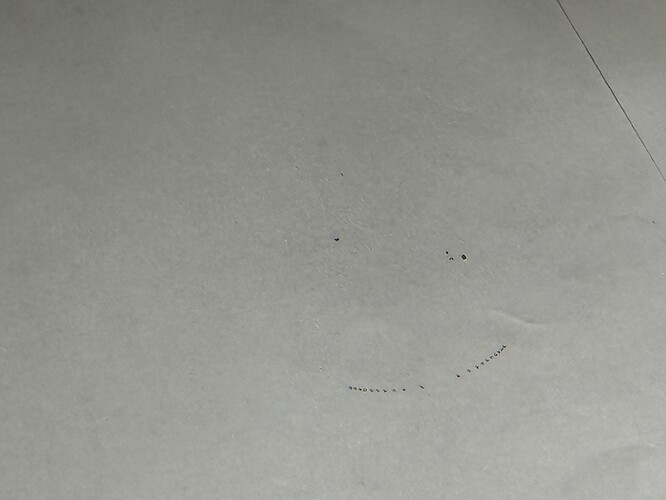

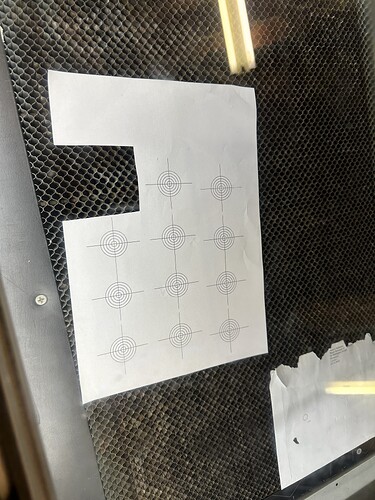

Lightburn moves the nozzle around, and homes (all correctly) but only when in packet usb mode will it turn the laser on. (When in serial mode it moves around correctly but the laser won’t turn on !?!?!) A simple test circle will only just mark a piece of paper even with power at 100, moves at 1mm/ sec. So clearly something odd Is going on and I suspect firmware / the communication protocol.

Given how old this is it feels like getting a ruida controller panel is a “must do” but maybe only once I’ve ruled out firmware bugs / other problems, as if the controller is itself somehow pooped I don’t want to buy a new panel for it to then throw it away when I buy a new inevitably upgraded controller that is bound to be incompatible with the panel I’ve just bought … So - to start it would be great to check if the firmware on the ruida controller is up to date - but I have no idea where to get firmware files from, nor how to install if I can’t get Rd works to talk to it. This feels a chicken and egg.

Dumping the controller and starting afresh is an extremely expensive way of updating firmware however !

Is there a website out there that lists what the latest firmware versions are for the various ruida controllers out in the wild?

Any suggestions ?

Thanks hive mind!