You may have this option in the File menu.

I don’t see that happening … It has to know what kind of machine to be able to generate code…

His laser isn’t configured completely/correctly

![]()

@jkwilborn thank you! And will do. I think I will also delete everything, do a reboot and reinstall. Just in case something went wrong with the LB install. It just seems weird that my interface is clearly different from what I’ve seen here. And I did try (more than once) to do the manual profile setup. Which seemed fine each time.

I’ll be back….

![]()

![]()

A bit of a delay - sorry. New user here, so was limited in number of forum replies I was allowed to make in the first 24 hours lol.

I did get it to work in that time out - sort of. Did a delete/re-install. Which didn’t change the proper profile (still no save buttons) but did change the incorrect method of profile creation.

I again did what LB says to do as far as setting up a non-connected profile. That still didn’t work. Seems like a software issue (not likely a bug, as much as the way it’s designed).

It just doesn’t seem to want to work without being directly connected. It’s a pity you can’t just select the laser type from a list or create your own profile independently of being connected to a laser. If you can, I can’t so far.

The second profile I set up was another attempt to connect with wifi / lightbridge which failed as expected, but this time when I backed out of it it left the profile.

So I can now send a file to the SD card. Yay!!

But… I don’t think it’s correct. If an .nc file is like gcode, some codes must be auto configured in LB that are making it act in unexpected ways. I’m trying to adjust for it rather than fix it as… already spent too much time… but I’ll mention it incase one of you knows a quick fix.

It’s to do with origin. As in I printed file three times and each time it seems to use a different origin. (Perhaps because profile is wrong).

I’m expecting it to use the bottom left (closest left) as the origin. I manually move laser to origin and use laser panel to confirm it as origin.

Settings (somewhere in LB) were relative (not absolute) to origin. But it printed near middle of area. And then once so far back and right it slammed into chassis. And third time at bottom left but about 3” too far down (close to front) so that it printed right off print area. My print bed now has a lasting souvenir of the event lol.

Anyway… as one who has en entire 3D print farm at my disposal, lasers and LightBurn are making the technical challenges of 3D printing look pretty easy! Not what I had expected. The crappy app that comes with the elegoo laser does work. But it’s pretty crappy.

Which is why I was hoping LB would work. Maybe I’ll have to use a labtop or something to generate a working profile and then move that to the PC some how?

Is there a way that could be a viable work-around?

And thanks for all your assistance. I do really appreciate it.

I’m also open to suggestions for other software if you have any. ![]()

The Lightburn Bridge is for Ruida dsp type controllers only. Doesn’t support grbl (your controller).

I have a DLC32 that is configured for wifi, but I still haven’t gotten it connected so it might not be so straight forward on some machines. I’ve fooled around with it, but still no connection and one of them was talking about using telnet to connect… Haven’t had time to chase down exactly how the grbl wifi boards interface… There seems plenty of people around that have done this.

This should be easy to setup… maybe we should go through the setup, sounds like you’re missing something.

If you did get output for your devices, Lightburn would have to know what the device was for it to generate code – and give you buttons.

I always cringe when people delete re-install, reboot — this is why I left windows… This should not have to be done, IMHO… I gave up on windows over a decade ago.

![]()

Following my post:

- First place a PC/Laptop near the laser

- Create a device by importing ELEGOO PHECDA lightburn configuration.lbdev. (Lightburn can work with a device defined and not connected, but first you need to make sure it´s the correct one and and that it works correctly).

- Check that everything works properly.

- Place a fire extinguisher / fire alarm near the laser.

- Setup a WIFI/IP webcam pointing at the laser.

- Then migrate all the configurations to the other PCs.

Moving LightBurn To Another Computer - LightBurn Documentation

Thank you.

Using the LB documented instructions led to a device that had no controls.

‘Faking it’ and half completing it as a wireless profile got me controls. Just not exactly working output.

Clearly the software was designed to only (realistically) work by being connected directly to laser (at least at some point).

I will use a Mac lab top to make a profile. And then transfer profile file to PC if I can make file and find it lol. I did find a file out to there that is supposedly a profile for the machine. Which variant, I have no clue. (At least 4 I know of)

There is no option for us to have LB on PC be connected to the laser.

Production area is separate from PC’s.

It’s a shame you can’t just grab a profile from a preconfigured list and/or make your own manually.

Maybe there is? I’m sure the profile generated is a text based file. Are there any LB docs on what format is used?

Interestingly, I have found many posts out there with the same problem, with no solutions. (Not on this forum)

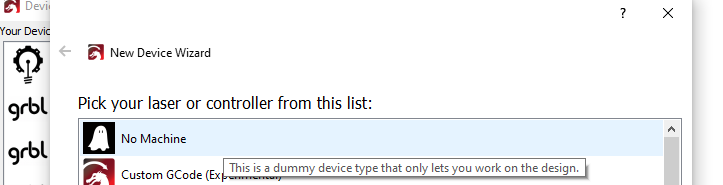

The ghost icon means you created a dummy device, not an actual laser profile:

Since it’s a dummy device, it has no idea what kind of laser you’d be making data for. If you have a GRBL based laser, you need to create a GRBL device, and then LightBurn knows it uses GCode and you’ll have the option to save data in that format.

In the Devices window, click ‘Create Manually’ and choose GRBL from the list, then tell it the size, and give it a name. That’s it.

LightBurn never requires that you are connected to a laser, but it needs to know what kind of controller the laser has. We are working on a method to allow users to choose from a list of lasers, but there are far more lasers out there than there are controller types, so we currently let you choose by controller, not by brand name.

Thank you. I truly appreciate the help and the reply.

If I may, I suggest perhaps some rewording to your manual to more clearly reflect this. If you read it again, you might see what I mean.

In the end I used a MacBook to connect and make a profile. However many of the options disappear when the laser is disconnected, which kind of makes sense but I would prefer that the same controls (in my specific use case changing settings for limit sensing) remain accessible, with a ‘sync’ option once it’s connected.

Of great concern to me is that when I created the profile with the labtop connected to the laser machine turned on, the laser itself came on! I can’t repeat it. I tried. I have no idea why or how. My arm was resting near the Laser panel, not sure if I was touching it (display panel is also touch screen input). Why would I have my arm there? I was trying to balance the laptop without it falling onto the concrete floor. As the screen was hard to see with reflections, I had taken my laser glasses off. Bam! I saw a bright purple blue light in the corner of my eye. I yanked the plug on the laser. It was only a second or two at the most, it wasn’t aimed or reflected directly at me thankfully, but my eyes were completely unprotected. I have no idea if my eyes were damaged by the reflected light. I don’t think so thankfully.

I realize your software is designed to be used to actively control and run the laser, but I think it should not be able to turn laser on at all directly. Software is never perfect. It’s just a bad philosophy to let LB have the ability to independently fire the laser. Or at the very least, some kind of ‘are you sure?’ dialog to confirm. If the work flow was centered around using a card to transfer work, it would seem way safer to me. Mess around with file, safely get it prepared, transfer file physically to laser. Make sure work zone is safe, covered, exhaust on etc. Then hit the ‘play’ or ‘run’ button (which should always be remotely wired and not on laser machine).

I’m the first to admit I’m a newbie and that my approach may seem counterintuitive to those who have been using lasers for many years. But with the recent influx of new users, maybe it’s time to come at this from a new perspective.

Nothing stopping you from having different modes for those who don’t want changes.

As for me? I now have electric tape over laser anytime LB is connected to laser. I can’t trust it.

I’m now trying to update eprom and/or firmware to properly recognize limit switches I installed. Challenging when LB control panels disappear when not connected. I’m gobsmacked that you can even buy a laser without limit switches. I suspect as this market matures, lots of changes will be coming.

I hope you don’t mind the feedback.

![]() 8

8

Can you be specific about what disappears?

The only time you should be missing any buttons, is when the software doesn’t know what kind of machine you have.

If it connects, it’s synced — Lightburn doesn’t change the machine configuration when it connects so what else are you thinking it could sync too and why?

If they can’t duplicate the issue, they can’t fix what they don’t know is broken. It doesn’t help that you did not get a chance to look at Lightburn to see what it was doing.

Then it wouldn’t be usable in many installations… this is what a laser control program does…

Lightburn cannot cause a glass tube co2 to lase.

If you frame your object via Lightburn, you have to turn the laser on to do this in most instances. It’s only there because it’s needed.

And hardware is?

Never thought I’d hear this … go back to sneakernet? Not a chance…

Safety is between your ears. Engage brain before operating anything. Fear causes more injuries than most people know.

Millions of these are out there – being used by people with a lower IQ than a bag of rocks… rarely if ever hear of any them being blinded, burnt or electrocuted.

I guess it’s all relative… have fun ![]()

![]()

There is nothing in the LightBurn code that does anything with your laser to tell it to turn on when it connects.

There are exactly three times LightBurn will send the command to turn on the laser:

- When you push the “Fire” button in LightBurn (which you have to enable, and set the power to non-zero)

- When you click the Frame button (and have the fire button option enabled, with a non-zero power setting)

- When you run a job that includes a layer with a non-zero power setting

It’s feasible that your laser head got some electrical noise in the wire that triggers the laser, but it’s extremely unlikely that LightBurn triggered it. We take that kind of thing very seriously, and put a decent number of safeguards in place to prevent it from happening unless absolutely intended.

@LightBurn I realize the importance of this bug, which is why I brought it to your attention. Like most bugs, I doubt it was intentional.

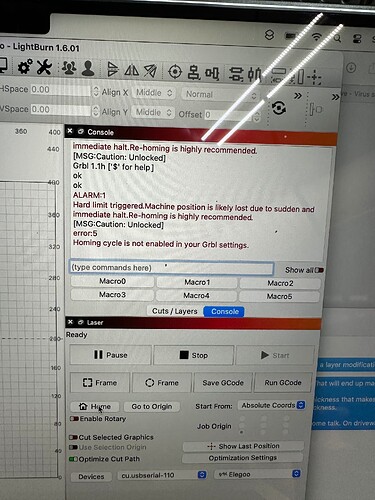

I was able to repeat the unintended firing one more time (unintentionally). I took a photo of the LB page at the time, and the laser was on for at least 15 seconds until I turned it off. No axis was moving. The laser came on exactly after clicking the LB ‘home’ button. It is entirely possible that the laser firmware caused this not LB or some kind of undocumented interaction between LB and Phecda, I have no idea. But it fired from no action (by me) other than clicking the home button. I should also note that the first time, the Phecda was running the old firmware. The second time it was running the most recent one.

This time I was very conscious of my actions since it glitched before. I do recall thinking that I clicked home with the first instance, but wasn’t 100% sure. I am 100% sure this time. So maybe safe to assume both times the ‘home’ button started this somehow.

This time I was wearing laser glasses and the only light that got out was from bouncing around inside the air nozzle and leaking out of the clear air hose tube. And nothing was touching the screen/panel. Considering the small size of clear tube and that the laser end of air nozzle had black electric tape over it, it was much brighter than I would have thought. So I can only assume a fairly high light value (but that’s a guess).

This was after a reset of laser. Using MacBook and current LB. Let me know if I can provide any other info. Of note, I was testing limit switches prior to this screenshot. Also note that at the time I took the photo, the laser was still firing (behind laptop).

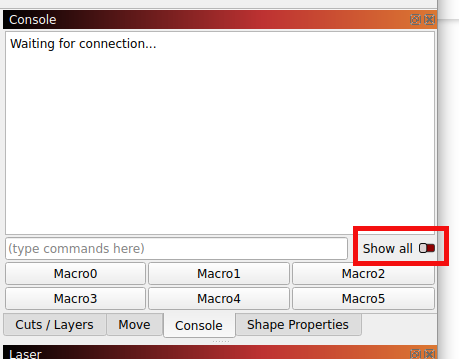

Turn on the “Show All” button in the console window there, then right-click on the “Devices” button to reset the connection to the laser and try this process again. You’ll be able to see everything LightBurn sends to the laser - all GCode commands.

Clicking the Home button sends $H and that’s it - it tells the laser to home itself, as that process is only initiated by LightBurn, but carried out entirely by the controller. There should be nothing in the commands sent that could enable the laser.

As a complete aside - you can get WiFi enabled SD cards https://www.dpreview.com/reviews/battle-of-the-wi-fi-cards-eye-fi-vs-transcend

Though how well they work I have no idea in a laser application. I’ve used them on 3D printers before.

Just thinking out loud here… Is there any chance the two issues (reason for my original post) and the unintended firing are related? Could the LB screen have mapped the play (or some other action) onto the ‘home’ area? As you may recall, there were no action buttons (in my case no save to SD). Loading the different profiles causes different buttons to show (graphics and input areas).

What should I look for? Happy to copy paste it to you.

![]()

If you see an M3 or M4 command, that would be enabling the laser output. If you see G1 with a non-zero S value following it, that would be setting the power.

Looks like I shut down LB after that. Console doesn’t show the event. Does LB keep log files for the console?

No, and you would need to re-do the same process that triggered the laser as you did before, with the ‘Show All’ button enabled. It only shows commands that are sent after enabling that switch. It’s not retroactive.