hi, how i solve this ploblem?

What is the problem?

Can you provide more details about your machine and the file that produces this result?

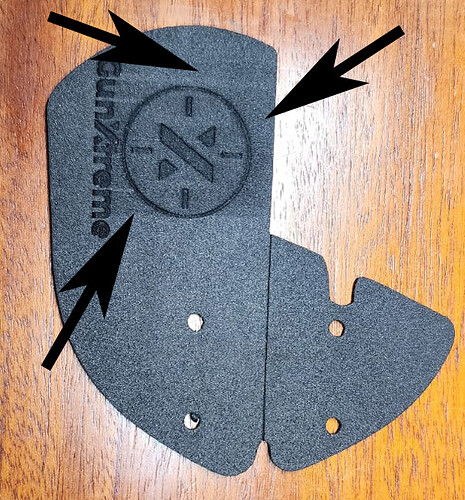

It appears to me that the laser isn’t turning completely off (or low enough) during a scan/fill operation.

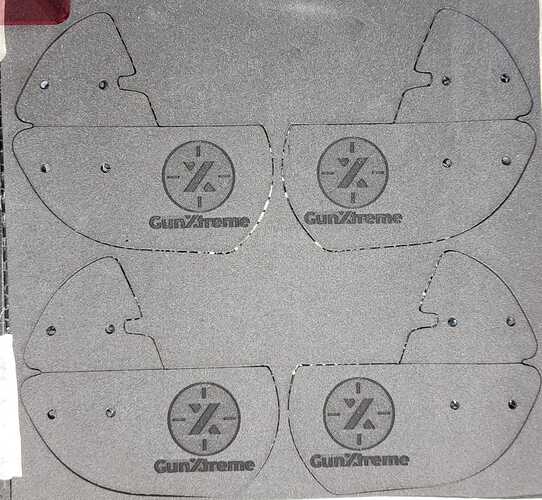

It could look like felt material and to me it looks like you are using wrong engraving parameter. That is what I can say with the meager information you have given.

I was thinking felt, too. Originally I suspected smoke staining, but the edges of the defect/shadow/stain seem too sharp.

hi,

I´m using ender 3 laser whit gcod in the card.

I believe in your theory that the laser does not turn off completely. The problem is how to solve this?

hi ,

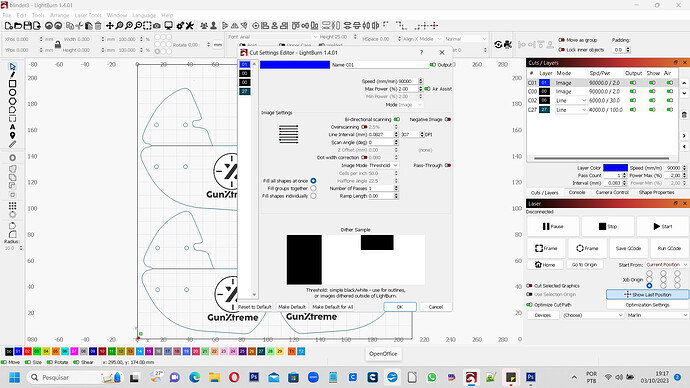

It could be parameters, but which one?

… it’s always the parameters, but without info no possibility of help.

Show your current settings in Lightburn and we will go from this point.

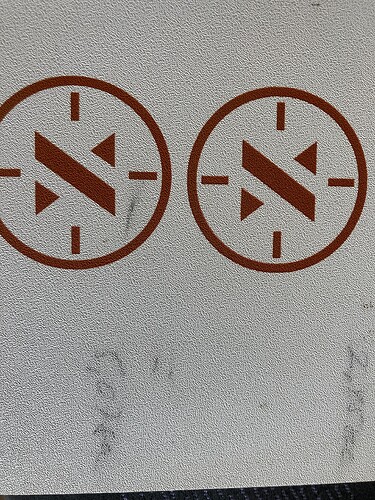

I have made some experiments on a material which is based on acrylic and very well reproduces errors during engraving. I have tried to get the settings as close as possible to your values. The upper one is engraved as a picture (like yours) the lower one is engraved in normal fill mode. I cannot reproduce the error you describe/experience, therefore I assume it is a scan offset problem, especially with the speeds you are using.

What does your preview window look like? If you only test on the logo and use a more moderate speed, how is this result?

(speed is set to 500mm/sec which is my max, the real speed is written next to it in pencil)

Your profile indicates you have a Creality Ender 3.

I don’t think that machine can come remotely close to 90000 mm/min and with 2% on even the 10W module, it is a miniscule amount of energy. Probably not enough to even lightly mark thermal paper.

That would be 1,500 mm/sec on Bernd’s machine. Three times his machine limit. My machine is advertised with a max 48,000 mm/min and it’s positively useless at half that. I’m a little surprised Lightburn didn’t throw an error just trying to calculate the GCode.

Something doesn’t add up here.

Can you confirm your machine specifications?

Is this material EVA foam or something with similar low heat tolerance?

I cut 1.5mm black EVA foam at 1500 mm/min & 35% with a 20W diode laser. Clean cuts, very little melting or curling. I haven’t tried engraving it, but I can attempt if that would be helpful.

1.5mm EVA, 18mm height Arial text, 1500mm/min @ 35%

…mmmm, shouldn’t we say 1500mm/sec. ? ![]()

This may be a really stupid question, but the cone isn’t dragging on the surface right?

:embarrassed:

Um, yeah…yeah. My bad. I’m used to going the other way, I guess. Sorry.

Still ridiculously fast.

Not stupid at all! Good thought, in fact, but I think the marks that go off the right of the “G” and the reticle with nothing on the left make that unlikely.

hum okay. Well my next thought I can’t find the information for. I’ve been searching to no avail, but I’m pretty sure I saw someone post recently that they has an issue with a diode laser not completely turning off after it had been turned on.

There are a few things that are a little strange.

Orientation of the result in the photo does not match the orientation in the setting, discoloration or possible overscan will be rotated 90 degrees.

There is no visible discoloration from the final “e”.

Can’t you do a little test with an array of 5x5 squares with 10x10mm with 3mm distance and your power and speed values?

The “e” stood out to me as well. I didn’t notice the orientation. Good catch. Yeah, extra odd.