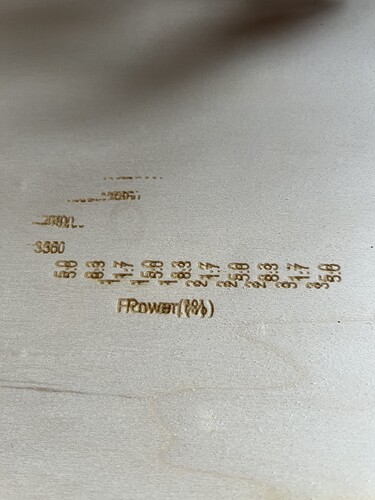

I cleaned my optics myself yesterday for the first time. When I ran the machine after, it’s cutting fine but engraving double or with a shadow ![]()

I’m not very mechanical, so I’ve no idea what to try or check to rectify:(

Any and ALL help GRATEFULLY RECEIVED ![]()

From a desperate blond girl in the UK

hi!

As you did clean the lenses make sure non is a bit loose in the holder.

If your machine was a diode I would immediately ask you to check your belts.

Given that is a Co2 possibly you need to do some scan offset adjustment.

I would still make sure that your X axis belts are on point. Your ghosting don’t seem consistent

Hi thanks for this-I double checked everything was re secured!

Excuse my ignorance, but can you please PLEASE explain how I go about doing what you’ve suggested, il give anything ago but very clueless:crazy_face:-so if u could explain like I don’t have a clue I’d REALLY APPRECIATE ![]()

Turn off bidirectional fill (scan) and see if that corrects the ghosting.

Scanning offset is possible, but it’s so far off I doubt that’s the issue…

It’s always nice to have a little background on it’s history. If it’s new and has always been this way, that a different troubleshooting path than if it’s been operating and all of a sudden this occurred.

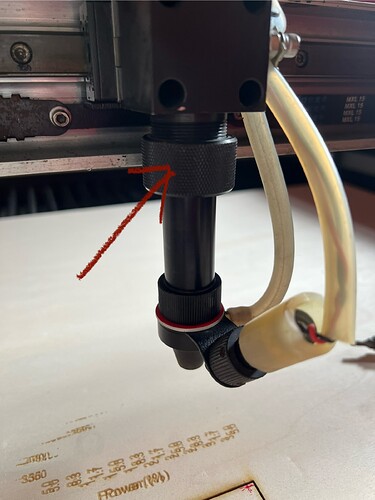

This is suspiciously like a loose grub screw… This is the set screw that holds the pulley to the motor shaft.

When these become loose, they can allow the pulley to slip a bit as the machine changes direction…

You can do this but leaving on, so the motors locked and try to move the head a bit back and for to see if it will show some slack.

Good luck

![]()

Thanks so much for ur response ![]()

Blockquote

It was working absolutely fine before (not long since serviced), so this ghosting just happen after I removed the lense to clean, I thought I may have not tightened it in place properly so I removed and refitting and made sure it was all secure! I’m really clueless on the mechanics of the machine (and desperately trying to finish a job)-could you explain which bit u think may be loose? If the arrowed bit-it’s not loose, I’ve checked and checked again:(

If you removed the lens, it’s likely not snug enough. This would account for the issue with the image shifting.

Doesn’t take much… Remove the tube and ensure the lens is held snug. Most of these have a silicon washer to snug it up against. I just go to ACE hardware and buy 0 rings that are a bit smaller than the lens tube and cut it in one place and use it.

Lenses are glass and very fragile, so be gentle…

Good luck

![]()

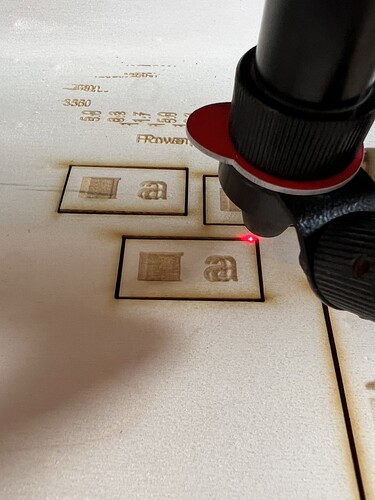

I did a pulse line test, and just a pulse test on the line when it pulses and is moved at same time you can see the shadow, but when just pulsed in situ there’s no shadow?!

Anyone make any light of this besides the lens’s being loose as it’s not?!

You kind of lost me… Which problem are we looking at?

Did you try disabling bi-directional scan?

If you don’t answer the questions it’s hard for us to help you.

The spot size is about 1mm, and it should be about 0.20mm or about 1/5th the size.

The brown areas could be the debris caused by the burn itself.

When you mark something, don’t make it black. Some of the information about the beam is lost.

![]()

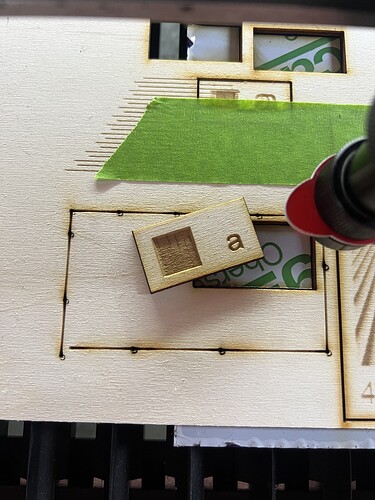

I tryed turning off bi direction it’s the one on right in pic, and the one on left is with out air assist.

I’ve exhausted optics-I’m happy everything is straight etc.

On another note-there’s a vid of belt-should belt look like this on the back-like as slack?

None of my machines belts do that… have you tried snugging it up?

![]()

Fixed, some help from Ryan Turner (@studio_t_uk) • Instagram photos and videos

It was the belt-tightened-and no shadow ![]()

![]()

![]()

Thanks to STUDIO T, and for all the help on here! Really appreciate-and I’ve learned a lot trying to rectify, so every cloud🤪