I think you should run it with your black values and vary the interval… if you look at the dog tag I posted, you’ll see the effect of that minor change. @Texaswoodcnc changes his interval on his dog tags.

You are mentally locked into the speed/power game of a co2/dpssl laser… these work differently.

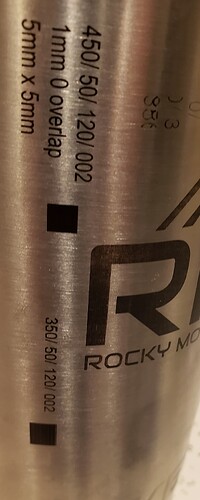

You can vary speed and interval or power and interval… With an M7 we also have the Q-pulse duration. The q-pulse on all of the dog tag was 8nS, you can’t do that with your machine.

I got a JPT source manual for mine, from Russ Sadler, he happened to be helping someone with the same machine and got it from Cloud Ray. I think it helps to read over these and know what the machine is capable of doing. I’d contact the sales person and ask for a copy of it and the galvo head they used… Really, what can they say?

@Texaswoodcnc also posted his dog tags and he is varying the interval also. The q-pulse he’s using is probably close to your pulse duration. I figure the conversion with a Raycus as a 150nS pulse width… I suspect a JPT Q-switch is probably pretty close.

When you were asking about purchasing a machine, I (we) asked/suggested to you multiple times about getting a machine lacking all these adjustments… and specifically that there was limited ability to do color type work.

You constantly poo-poo’d the idea… now you are hot to trot for that very thing, but I’m afraid you made your bed and will have to sleep in it. ![]()

I think you had enough people advise a more flexible machine.

I think the people that sold it to you should have advised you of the difference in costs and abilities… we did for abilities, anyway.

Seems like it always ends up being money, so I can’t fault you there… from that point of view.

However you have to understand the limitation… and this is probably one of them… remember you saved a few grand, probably… ![]()

It is great you have a fiber, so hallelujah on that.

Maybe you can dazzle us with your cleverness and get it to work to some degree. ![]() I think that’s possible.

I think that’s possible.

Good luck… we’re watching

![]()