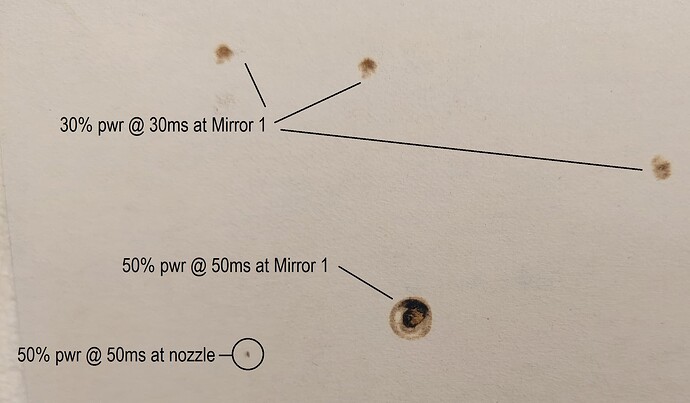

A friend of mine (some 25 years now) bought a new Mishi 150W CO2 laser about 6 months ago. He owns a small sign shop and wanted to add a laser to his “tool kit” of machines. I begged him to call me before he fired it up so I could make sure it was done correctly. It’s now too late, and he’s damaged it, I’m just not sure what’s broken. As the picture shows, the beam pulse at M1 shows an oddly shaped burn, with nothing at the nozzle (30% pwr, 30ms pulse duration). The last pulse was done at 50% pwr and 50ms, and although there was a mark at the nozzle, it didn’t go through. The power supply doesn’t have a current meter (I’ve ordered an analog 30ma meter to bring with me on Monday when I go back to his shop). Also, I realized as I was shutting everything off that the chiller was reading 28 degrees C, he had never set it up. My guess is that the tube is bad, possibly from running it at room temperature (in Florida) at 85% power trying to engrave a 6" square block of text (his logo), multiple times. Is there a test I can do to rule out the power supply? With the ammeter hooked up, what could I expect to see from a bad tube? A bad power supply? I know I’m asking a lot on very little information, but I just want to avoid shotguning parts until it works. I would really appreciate any advice you can offer.

Opinion: The tube is toast and the power supply is fine.

For a 150 W CO₂ laser, a 50% @ 50 ms pulse should punch right through whatever you’re using as a target at M1. The fact that it produces cute little rings says that it’s not operating in TEM00 mode, which means it’s wrecked.

He’s gonna write that tube off as experience.

Thanks Ed, I had come to the same conclusion, I just wanted an experts opinion before I deliver the bad news.

That would not be me, but I have watched similar diagnoses play out. With commercial use under the best of circumstances, tubes seem to last a few years; six months is short, but this situation wasn’t the best.

Generally there’s a whole lot of denial up front, bargaining with cheaper hardware, and so forth and so on. Worst case, there’s a spare on the shelf that will come in handy some time soon.

The sad thing is, although he bought it six months ago, he had just turned it on and attempted to use it within the last few days. When he first got it, I counseled him to join the LightBurn forum and read, read, read.

Maybe not, but you are way ahead of whoever is in second place.

By a mile at least, that’s for sure.

That being said, I’ve never ordered a tube before. That label says 130W, 150W peak. I haven’t had a chance to go back and look at the power supply, but for the sake of argument, let’s say it’s rated for 150W. Should I be searching for a 150W tube, under the assumption that they are listing its peak output? The other thing I have no clue about is where to buy it from. From a quick search I’ve seen a 130W run from $385 at Cloudray up to $1500, from other sources, for a 150W. I’m just not sure what I should be looking for, or where. Any suggestions? I suspect I should start a new thread with this question.

AFAICT, everybody advertises the tube’s absolute maximum possible power output, rather than its rated / useful / practical power, so, yeah, that seems like a pretty good assumption. ![]()

Perhaps an overly cynical view: given the machine’s history to date, it won’t matter.

The actual tube performance doesn’t matter nearly as much as it may seem, at least within reasonable limits, because “a small sign shop” won’t be pushing the limits right away. In fact, an overly powerful tube may produce suboptimal engraving results on most materials, due to its inability to fire at lower power.

Despite some recent warranty avoidance issues reported around here, Cloudray / LightObject seem like actual companies with some attention to detail, as opposed to randomly named Amazon sellers. Buying directly from them avoids the interference you get with Amazon; trying to contact a seller through Amazon is futile.

Bottom line: replace the tube with a relatively inexpensive tube from a known-good source, set it up, and use it until it either drops dead or the need for Moah Powah™ surfaces.

Ed, thank you for your astute (as always) answer. As an aside, I stumbled across your blog post (on TSoMSitM) about changing homing direction and it was spot on.

Ed, just wanted to give you an update. I went back to the sign shop a few days later, got the chiller set up correctly, and once it was at temperature, started a basic alignment procedure to show him the tube was bad. It wasn’t. It was way out of alignment. With the tube running at temp, I was getting a pulse that was high and right at M1, but I had a good TEM00 burn. After several hours of adjusting the mirrors (I found out one of his employees had tried his hand at alignment) it came down to getting the beam centered on the very small nozzle opening. I was getting good pulses at all three targets but nothing out the nozzle, turns out it was hitting just inside of the opening. After five hours of “iterations” (as Russ would say) we had a very nice, strong, pinpoint dot on our scrap piece of wood. I bought a milliammeter to bring with me and the current draw was within the range of what I would expect for the small test engraves we were doing. I made some custom-built target holders and targets (based on Russ’ design) and I’ll be giving the laser one final four corner check before washing my hands of it. We’ll see how long it lasts.

Truth: I’m glad to be wrong!

The picture showing the burn at Mirror 1 remains puzzling, because the beam shouldn’t have that ring around it. Perhaps there’s so much power available that even the fringe area’s mojo will char the paper.

What does the beam look like now?

I’ll use this as justification to recommend starting with an alignment, before assuming the tube is toast based on all the evidence so far. ![]()

I’m going back on Monday to recheck all the adjustments we made on the 16th; I’ll make sure to document everything. I have to say I’m just as surprised as you that the tube appears to be okay. The sign shop employee told me that he only ran it for a few minutes each time and only for a couple times before sending up a distress flare. It’s not my machine, but I felt bad that I was going to have to deliver bad news, and so happy when I didn’t.

I’d be interested in seeing a fresh M1 test if you’re able to get one. Curious if the original was an anomaly.

I’ll be posting it Monday evening when I get back from his sign shop.

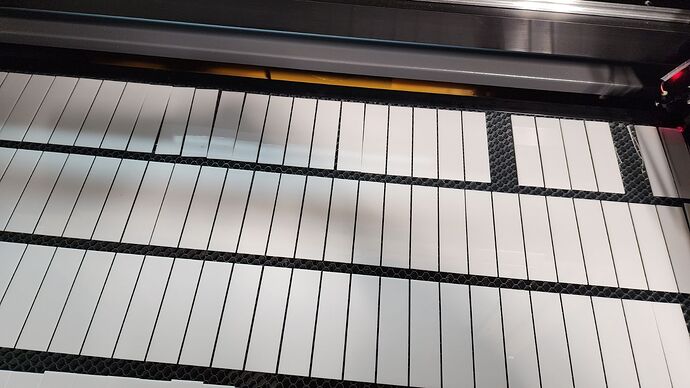

First off, let me apologize for taking so long to get back with an update. I wanted to wait until they actually ran a job on their laser. Yesterday they ran a sheet of 2mm acrylic (900mm X 600mm, the full size of the bed) cutting out 145 pieces at 102mm by 32mm (4" by 1.25"), when we lifted the corners of the sheet all of the 145 pieces stayed on the bed. I knew what the settings would be for my 60W, so I had to take a WAG at what they would be for this MISHI 130W. We ended up using 25mm/s @ 35% power. I have no idea if that’s good or bad (perhaps someone with a 130W machine can chime in). I spent eight hours, over three days, trying to undo what their employee had done to it, I admit I felt a certain amount of elation when all those bits of acrylic dropped away. “Never give up, never surrender” (Peter Taggart)

M1 target.

Job complete. (we paused it once or twice to make sure it was cutting through)