I’ve been fighting this thing for a couple days now. It works fine in Current Position, but I can’t get over one hurdle. Possibly a mental block, but here’s what I’ve been trying to do…

- Home the machine and all three axes go to zero (of course). X&Y at bottom left, Z at top/highest.

- Get Position

- Set Origin

- Jog X &Y to workpiece.

- Autofocus macro [ESP500]

That’s where it falls apart. The Focus Macro resets all three axes. Get Position confirms this. Jog Head to 200, 200. Get Position confirms 200,200,0. Run focus macro, head moves down, contacts workpiece, then moves up approx. 8mm to focus height. Console confirms completion at that point. Get Position then shows 0,0,0…having never touched X or Y. So the focus macro zeros X & Y wherever the macro was triggered and zeros Z approx 8mm above the workpiece.

If I then re-home, using the LB home command, it homes all three axes and I’m back where I started…with Z zeroed at top of travel and focus position lost. Endless loop of fail.

Anybody else seeing this?

Got a viable workaround?

Am I doing this all wrong somehow?

I’m considering writing a simple macro to home only X & Y, but I would prefer to move the laser head up 20mm or so to make sure it clears any fixturing I may have in the homing path (but out of the design area)…I’m just not sure if LB and the machine can put all three axes back to cut position on starting the job. I tried setting the focus, then homing only X & Y (with $HX & $HY). That works. Unfortunately, if add any adjustment to Z, a Frame or Run command ignores Z (doesn’t return to zero/focus. I’m missing a piece of the puzzle but it’s closer.

I wish I could see the code Ikier uses in the ESP500 subroutine/macro.

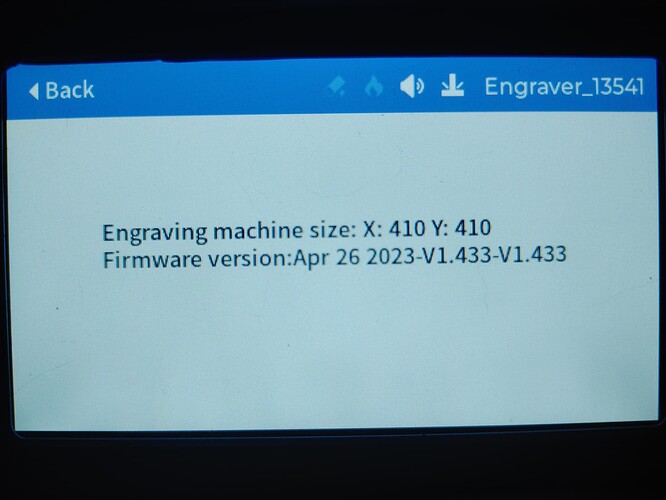

Machine has latest published firmware, 1.433. Dated mid Apr '23.

Probably unrelated, but of note…

I reflashed a few of the values in the firmware manually.

$10 to 0 (was 1) and $131 to 750 (was 410). I added an extension kit, which increases X from 410 to 750. I’ve been back and forth with Ikier and they can’t seem to understand that changing the physical machine dimensions should mandate a matching firmware…so I just did it myself. Power cycle (pull power connector for 5+ min) and reboot LB with fresh $$ on reconnect confirms changes were written to EEPROM.