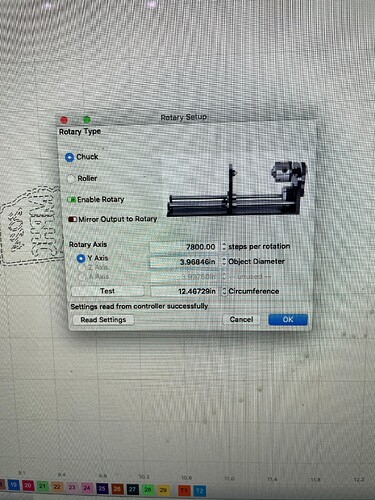

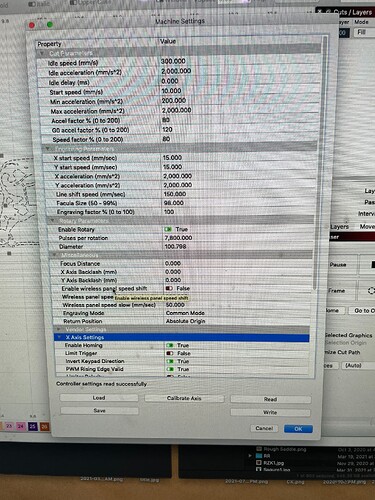

Hey there, so I’ve been using my laser for a couple of years, been using Lightburn for a couple of years. No issues thusfar that I haven’t been able to figure out on my own; until NOW! I just got a CHUCK rotary and my images are massively wider than they should be. Did the steps per rotation, is on point and it did a job just fine before now and nothing was changed that I’m aware of. What could be the issue, this is a rush job and I need a solution quick!

Typically this happens if you didn’t set the diameter properly for your work piece.

I’ve measured the cup right. That’s not it.

- Check and ensure the rotary is enabled in the software.

- Are you sure about steps/rotation, that’s an odd value?

- Does it work correctly with the test button?

I forget to check mine and weird results…

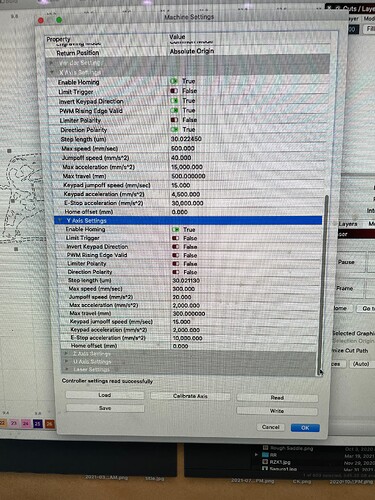

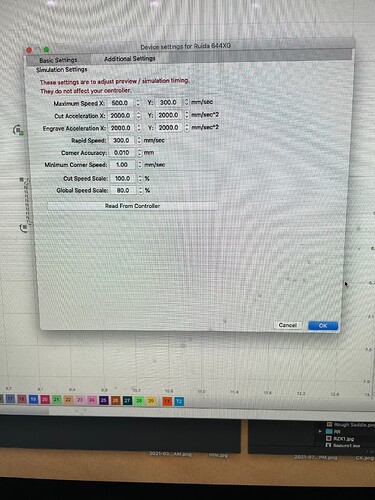

The settings are not easily changed, especially within the Ruida, so I’d expect, if working in the past, as something simple.

![]()

It was my steps… they were off even though it was lining up which is odd. So the steps is fixed and the image is fixed… but now the power is muddy, like it won’t go all the way through the powder coating like normal… and i’ve got it set to double what I normally use.

On the Chuck rotary, diameter or circumference is not relevant. The cup/glass/mug/etc. is synchronized with the chuck. Get the chuck right and the part will be right.

On a Roller rotary, the rotation rate of the roller and part is very different, and the second varies with size.

You’ve got them backwards… a roller or wheeled rotary drives the surface of the object, so diameter is not relevant…

A chuck dives the center, so to speak… the surface of a 55 gallon drum, chucked up, has to move faster than that of a 1" tube to do one rotation…

We are correcting for surface speed…

![]()

@jkwilborn is 100% correct, but I would add we are correcting for surface distance moved for each step with a stepper driver. Also, Looked at a couple different microstep drivers, none I could find do 7800. So unless you have a ratio other then 1:1 on your rotary, that is probably the culprit.

If image is stretched in the rotational direction, steps are set too high (or diameter is set too small) Try 6400 or 5000 if you don’t want to find your microstep driver and examine the dip switches.

I make sure it’s on before I start; but I have not had it before and you can tell.

Noo… they were right, the steps were just too high.

Yes, you have roller diameter for the roller attachment.

and object diameter for the chuck rotary.

It was the steps.

Ouch, no more late night replies!

Thanks for the help!!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.