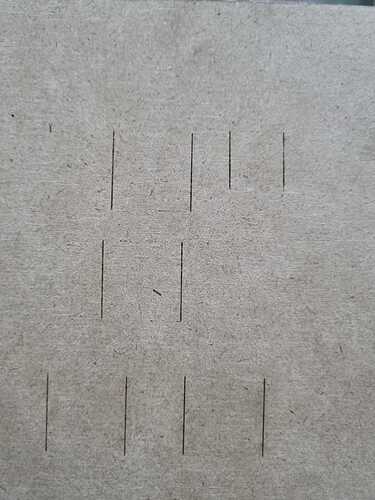

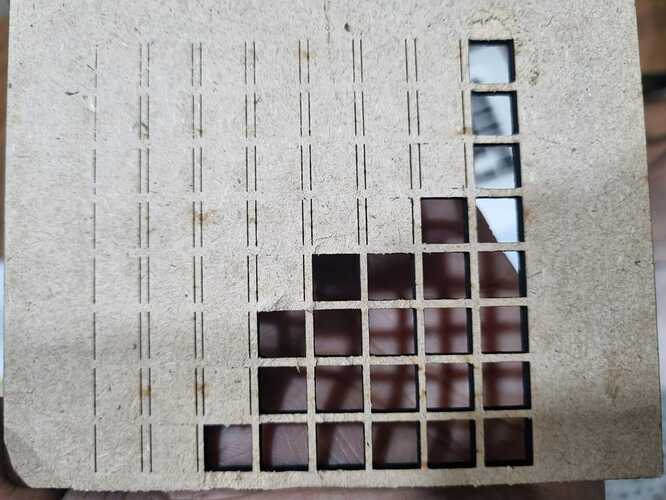

y axis shows no proper cut,while z axis cut is clean, its hard to remove material after cut, tried checking everything ,tighten the belt, found no issues with machine, what is the solution???

Diode lasers are not perfect dots on the spot size

This means that what you are experiencing is a result of the more rectangular shape of the beam

You need to account for the cut power of the wider beam (the y)

That will be the axis that defines how many passes/power you need

can u plz explain me the solution?

This is both normal and expected. Most higher power diode lasers behave this way. Easiest fix is to either slow down or increase power.

What Chris said, but what i meant is.

If one of your axis is not cutting the best, you need to use THIS axis to define your cutting parameters. The fact the X is cutting faster should be ignored

Slow down the machine and increase power until your Y make a full cut

THAT will be your real settings for cutting that material