Running out of ideas with this one and I hope you all could offer some advice. My colleague and I have been testing, adjusting, and testing more for months now and still aren’t able to produce a consistent quality. Trouble is, we don’t even know where to start looking…

We’re using a Boss LS-3655 with 105W tube.

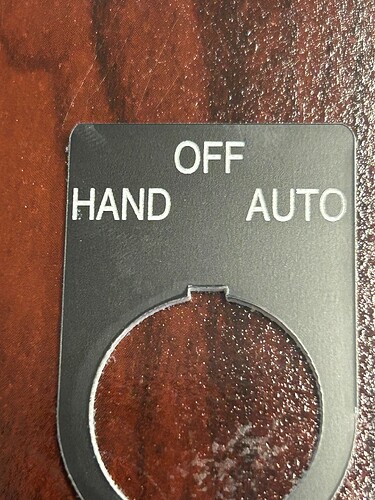

Our issue has been inconsistent quality across a sheet of legend plates on each batch. Some would come out excellent like this:

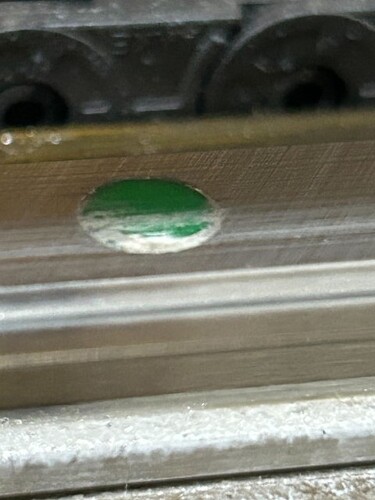

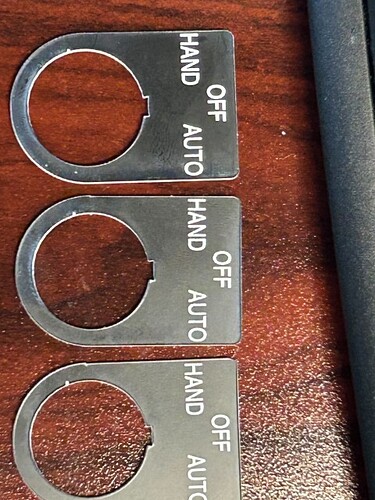

But others would be out of focus to varying degrees like this:

The frustrating part is the error is not consistent. We’re cutting a 12x24" sheet each time, so 96 plates per job. Some will be perfect on the sheet, others not. I estimate it’s a 75/25 split between good and bad respectively.

After looking at the fuzziness closely, we thought it might be a tracking issue (for lack of a better term) as if the laser was not firing at the correct location when the head would move from left to right or right to left. So we set lightburn to not use bi-directional fill and we got a single full sheet of perfect text.

But the next day, using the same settings, we’re back to our longstanding issue. We are the only ones using the machine so nothing was changed overnight.

Boss has not been of much help because after spending hours on support calls with them and aligning, shimming, realigning, cleaning, and you guessed it, more aligning…they pronounced our fuzzy results as “looks good to us”. And compared to the disastrous results we were getting at first setup it was an improvement. However our old laser, an Epilog Helix, has been producing excellent legend plates for 10 years or more without issue.

And this is only one of a few issues we’re having, none of which we can consistently replicate such as:

- Some legend plates in a sheet not cutting out completely

- Artifacts in the engraving (random dots, dashes, and lines appearing in places there shouldn’t be)

- Having to put a pipe character ( | ) for engraving on the far left in the scrap area otherwise the far left column text will be skewed

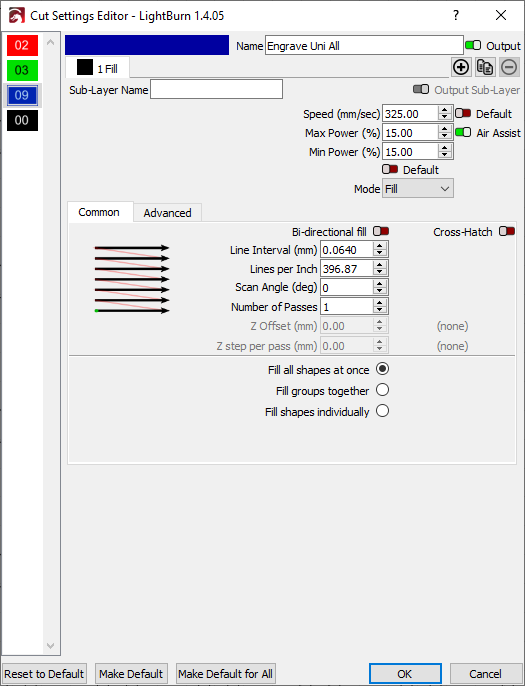

Here are our lightburn settings for engraving:

I’ve also attached our file:

22LP1-4530C-311_QTR.lbrn2 (939.4 KB)

Do we have our lightburn settings wrong? Are we having a software error? Or maybe a controller error? Mechanical error?

Thanks