Is the laser head supposed to be straight or slightly slanted?

My laser head got moved, and since then my machine is not cutting right. When I take off the nozzle it cuts great, but with the nozzle I need to keep raising the power. What can be wrong? It’s all aligned.

Two ways to make the head straight up an down/plumb with the bed. If you have a small square tool or a plastic triangle. Rest one side of triangle on the laser bed with other side vertical at one side of head. Straighten head so the side is flush with triangle and tighten the head. A small torpedo level will do the same.

The lens held inside the head mechanism may need to be aligned. That procedure has been illustrated in Light Burn.

This suggests the laser beam is hitting the nozzle, rather than passing through the aperture. If that’s the case, realign the nozzle so the beam is centered in the aperture.

You can verify the beam location by firing a test shot through a layer of tape stuck to the bottom: if the hole is centered, so is the beam.

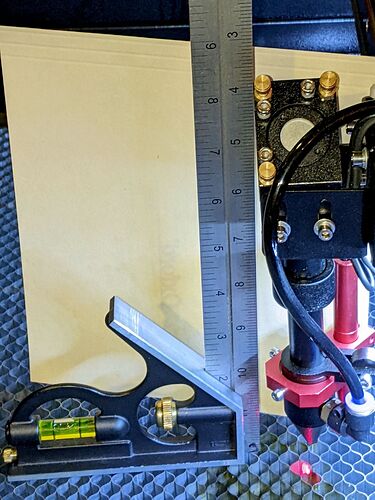

Weirdly, the head mechanics on my OMTech carries itself at a jaunty tilt, despite the beam itself being well-centered in the mirrors and the nozzle aperture, as well as being perpendicular to the platform:

But that is definitely not the way it should be!

More details on my blog …

If the tube is tilted, the beam cannot be going straight down the tube and hitting the lens without it being tilted also … ?

Can you get a target at the top and bottom of the tube to see where it’s striking these two locations?

Looks like you could correct it with the screws there…?

![]()

Dead center at both the goes-inta and comes-couta apertures!

I have no explanation for how that’s possible.

The X gantry rail could be canted or the stamped steel bracket holding the head to the rail might not be quite square. I have no convincing way to measure either of those without gutting the machine more than seems reasonable, given that it actually works, despite the rakish tilt.

Beam entry and exit locations should be fine as long as the laser is entering at mirror center and mirror is perpendicular to the direction of travel of laser. You could have the entire laser head rotated upside down and still be okay in that regard.

Wouldn’t the issue here be that the laser beam coming out of the lens would not be perpendicular to the bed at least on the XZ plane?

Do cuts come out square along the X axis?

By the way, unless you’re prepared for potentially hours of fiddling I’d not suggest taking this on as a “quick fix”. The available adjustment mechanisms are quite crude and affect multiple orientations at the same time. This makes any fine adjustment extremely fiddly with progress easily lost. There’s room for some innovation in this space certainly.

The only way this can occur is if the beam is also slanted the same as the tube… This would have to result in a non 90 deg cut…

So something smells… ![]()

I agree with @berainlb, unless you’re ok with down time, might just leave it…

This is what caused me to pitch the factory head…

I’ve seen so many suggesting that it hit m3 at center, that leads to a number of misconceptions…

I also know the head that came on my machine was rather misleading for it’s center… it isn’t as you can see…

![]()

Which is what I expected, too, but it hits the same spot (*) as far down as it still produces a visible burn.

Basically, everything is as good as I can measure, except for having the head tilted. I am definitely not inclined to mess with success!

When I get in the mood, there is nothing quite like a few hours of fiddling in the shop to soothe the savage breast … ![]()

(*) It actually orbits the same spot, because those four giant leadscrews stick up from their mounts with no guide rails along the Z axis, so the platform wobbulates a few millimeters as the leadscrews turn. Which is why I flinch when I read proposals to move the Z axis to track non-flat material.

![]()

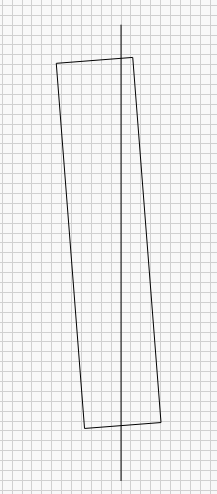

So does that mean the laser is aimed downward perpendicular to the bed but that the barrel itself is canted in such a way that the beam exits the nozzle at center but enters from the side?

Something like this:

I can’t express properly the many frustrating hours I spent chasing this after I crashed my head into the bed trying to sort out what ended up being a faulty auto-focus pen. If everything measures and performs well then yeah… best left alone. Or… a new device made that eliminates this frustration.

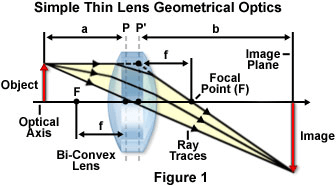

Generally agree… however if you use a lens like most of us … the beam will be be bent, as it enters the lens at an angle or off center.

Don’t know if this shows as most this as well as some laser lens diagrams, most assume the full width of the lens receiving light, not just a beam striking it off center… You can see the tack of the beams that strike off center…

Unless you want me to believe the tilted lens corrects the aberration…?

![]()

That must be the case, with the beam entering at the center of the top mirror and exiting at the center of the nozzle, with the entire head canted around the beam. Moving the head along X keeps the beam centered, moving the platform along Z keeps it centered, but looking at the combination square sitting on the honeycomb makes my head hurt.

Either OMTech spent a long time getting that mess exactly right before shipping it or all their mistakes canceled out on the first try.

You can surely predict what I think happened …

Thank you everyone! After hours of adjusting it now works! I myself don’t know what exactly I did right or wrong, but now it seems to work!

Comparing the accuracy of the laser beam and the square, I think it’s pretty clear you should replace the ORU… I.E. the square as it’s obviously broken… ![]()

![]()

It comes out only when the usual “bash to fit, file to hide, paint to cover” routine doesn’t work. If only it had an elastic scale …

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.