Sharing some additional internal discussion around the root cause potentials.

Oz: If their motor drivers use low microstepping, it absolutely could do this. Microsteps also have significantly less torque than full steps, so if the belts are over tight or the rails are dirty, that could contribute too. A starting point would be to check what the Machine Settings say the step size is for the X & Y axis. If the step size is large (like 0.05mm to 0.10mm) that would suggest low microstep resolution. Setting the current on the motor drivers too high can cause resonance and bounce when stepping which will also do weird things.

Not sure if the Polar controller has built in motor drivers or not, so it’s possible it could be tuned / improved.

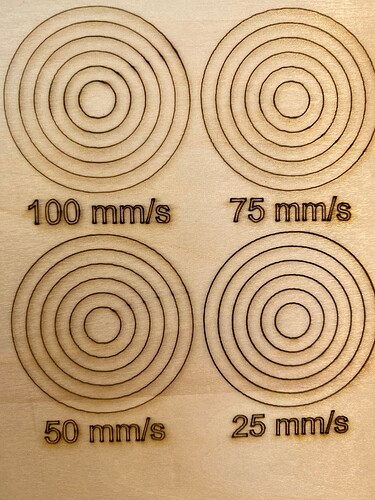

It may be worth reaching back to OMTech for further diagnostic suggestions / procedures to confirm and investigate potential adjustments for maximum performance tuning. ![]()