I’m having major issues with uploaded box designs made from any source. When imported, the tabs are always bigger than the slots. I have the xTool D1 pro 20 watt diode laser and the same designs will work fine in their software, XCS, although they don’t have the kerf option and the boxes are rubber mallet tight. I even went as far as to return Lightburn back to the original download, thinking I had changed something that was causing this but it didn’t help that issue at all. Any thoughts as to what the issue is? I have changed the SVG import from the 96 to the 72 so they come in the right size, just not the right dimensions on the tabs/slots. First time I thought it was the designers fault but it does it on every box I import from any box maker program I use.

Are you saying this occurs in the design or the issue presents only when burned?

Can you upload a .lbrn file where you see this? Can check if there are issues in the design.

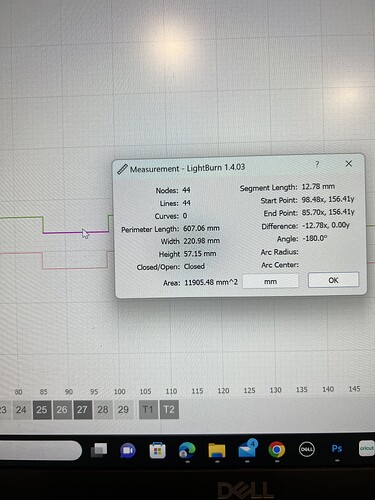

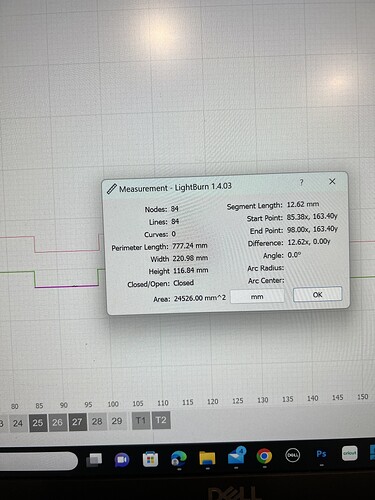

I’m not in my shop right now but I did take a screenshot of the issue. This is definitely not the designs fault. This happens with every box design I import and the same design cuts fine in the other software. And it shows on screen and cuts the same way.

You’re saying you’re cutting the exact same design in both XCS and LightBurn, with the same orientation and settings but you’re getting different results?

If I’m reading your screenshots correctly the tab looks like it’s 0.16 mm larger than the slot. However, the photo of the resulting burn seems to be much larger than that.

If you get a chance, please do upload a .lbrn file where you’re seeing this. The amount of difference seems larger than could be explained by the nature of the burn itself.

Ok. I’ll download it this afternoon when I get home. And yes it’s the exact same file being used and the one in XCS works.

Here is the box I’m working on. I purchased this design and it cuts fine in XCS but as you can see, the tabs and slots are not right in Lightburn and it cuts just like it shows. The picture above with the box that the tabs look bigger had the kerf cut on at 0.08mm too so that’s probably why it cut even larger.

Christmas Ornament Box.lbrn2 (17.3 KB)

I can see the discrepancy in the tab vs slot size. I doubt that LightBurn would be changing the design itself so I’m wondering if this is deliberate to account for kerf. Have you asked the designer about this?

Can you verify a few things:

- Have you burned this as-is without a kerf adjustment? Based on a quick review it looks like this assumes a .26 mm kerf (.13 mm kerf offset).

- Have you tried measuring the actual kerf of your laser for X and Y orientations?

- You’re burning this on the same material for both XCS and LightBurn

- The burn in XCS is not rotated 90 degrees compared to LightBurn

Can you upload the original SVG file as well? I’d like to if something is happening in the import to LightBurn.

So, this happens to every box I import into Lightburn. I’ve designed boxes myself and they’re fine in XCS and not in Lightburn. I have found the actual kerf on my laser and it is the 0.08mm. In XCS you can’t do anything with the kerf and the box is super tight but will go together with a bit of help from a rubber mallet.

Is it possible for there to be something wrong in the GRBL from xtool?

The symptoms are odd indeed.

A couple of working theories at the moment:

- It looks like XCS might round to the nearest 10th of a millimeter whereas LightBurn rounds to the nearest 1000th. I’m not sure if this is passed to the laser when cutting but if it does it’s possible that this accounts for the difference.

- The laser is calibrated differently when using XCS vs when in GRBL mode

Try a couple of tests:

- Create a 100x100 mm square in LightBurn. Then export as SVG and import into XCS. Burn from both. Measure the resulting burn. Ideally you’d do this with a caliper or something else that can measure very accurately.

- Create a 99.851 mm square in LightBurn. Then export as SVG and import into XCS. Burn and measure both.

What are the results from above?

I measured in the center both ways to get the numbers

These values aren’t as definitive as I was hoping they’d be.

One confirmation… height value for XCS 99.851 is “99.52” or “99.82”?

It’s not definitive but I suspect the difference in rounding may be the causal factor in what’s going on.

If true, I’d suggest slightly adjusting the design to accommodate the difference.

3 strategies:

- Use Tools->Resize Slots in Selection to adjust the slot width

- Use Offset Shapes tool to inset slightly both sides of the shapes

- Use an equivalent negative kerf to effectively increase the clearance

The number is 99.52. I’ll try your suggestions. Thank you for all your help.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.