Hello,

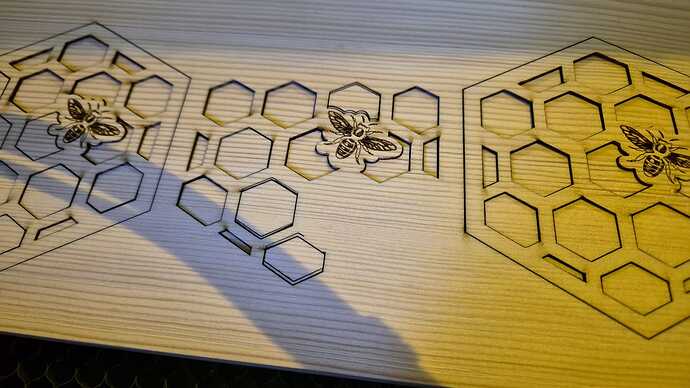

I have S30 Pro-Max with X-Y extension kit. The issue seems to be “skipping” some steps on Y axis. Some times it skipps by small margin, while others - it skips on every time it changes movement from X to Y axis.

Interesting part is that extension kit comes with 2 motors, and the skipps are happening on both motors at the same time for the same distance. I can run the job in the same area, and some times it produces double lines when running multiple passes. (with single pass cut some times it does not come back to the cutting starting point).

This particular case issue showed up 1h in the job, so I stopped the cutting, and restarted on the next coaster - all fine. After I finished this job, another job one was running great for another 1.5h with no issues in exact same area.

I have noticed that some times y axis makes clicking sound while moving along x axis - like trying to correct/re-align itself, and makes small notches (less than 0.1mm) along the X axis. Have not been able to catch it on camera.

Usual suspects - belt tensions, pulley grub screws, squareness of the laser etc has been checked, and I could not find anything too unusual, but I am close to 100% sure this should be related to laser itself.

I installed the extension kit, and was running it perfectly fine for a few months. I was moving the laser from one place to another therefore I had a feeling that maybe my Y axis rails are damaged (as it felt like it was binding a bit more on the middle part of the rail), so I switched them side to side and upside down, to make sure POM wheels are not the issue why laser could be binding - issue is still there.

The only thing that I am seeing that I can not seem to alingn better is belt is moving on both of the pulleys - to the right when laser moving up, and to the left when laser coming down, however the belt does not seem to be binding on the sidewalls of the pulleys. I can not find a way to adjust so the belt would be perfectly perpendicular and would not shift on the pulleys.

The interesting part, is that I can not have a guaranteed replicated issue from cut to cut. The most cases when this happens is if I have long movements along Y axis, however also with small 80-100mm movements on Y axis it sometimes produce the same issue .

Thanks in advance!