So, I just installed a door interlock and alert lighting on my fiber laser… I couldn’t find any documentation (and “support” didn’t grok the question at all), but I found a “Safety Enclosure” for my brand on eBay that had a wiring harness for contextual lighting, a door interlock, and a basic fan. I figured I may as well buy it for the parts and knowledge. (I stripped the parts from the enclosure and used them on mine – definitely wasn’t going to use the orange plastic pieces with no certification markings instead of my full enclosure with dark green certified 12"-ish window that cost as much as their entire enclosure.)

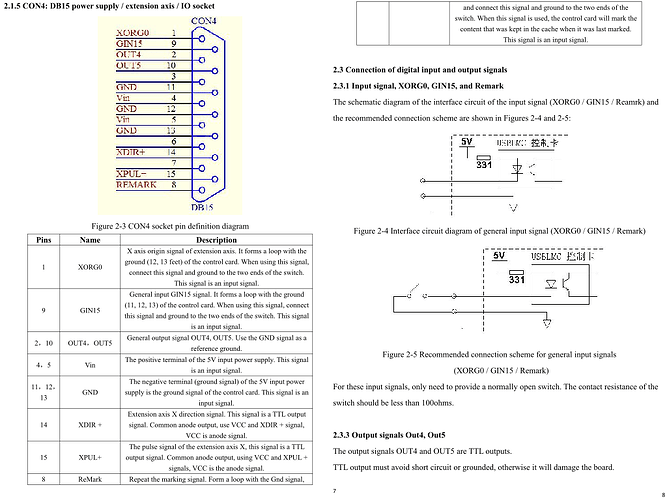

On my controller, apparently a “BJJCZ FBLI-B-LV4” (IIRC), there is a DB15 connector labeled something like “CON4 Power-motors”. I see the same connector and pinout on other ezcad2 boards for which I could find manuals online, e.g. “LMCV4-FIBER-M”. That connector is the one that exposes the few useful pins that carry the few signals I had to work with.

- Pin 1, XORG0, was connected to my existing foot switch.

- Pin 9, GIN15, was where the new door interlock switch connected.

- Pin 2, OUT4, was heading off into the cable bunch to the tower, and I didn’t bother with it, but it’s likely doing something, I guess?

- Pin 10, OUT5, was wired to a signal-level relay that connected power to some LED lighting (switching which of the R, G, and B buses on the LED strip were lit).

- Pin 8, REMARK, looks like it could potentially be useful for some people (run whatever’s cached again), but I didn’t bother with it.

So, I connected everything up, and then I just had to go into Device Settings and configure a few things on the Ports and Laser Settings, page. Specifically, for me:

- Busy Light: 5 (High)

- Start Marking: 14 (High)

- Door Protect: 15 (High)

The door interlock prevents you from starting the job, and if a job is running, it immediately pauses. (It’s a door interlock, which is what I wanted, not an e-stop, which the machine already had.) Also, it does not have any effect on framing. What’s even more useful to me is the LED lighting. When the machine is on, I have it wired to be a nice green (both inside my enclosure and also outside lighting the handle), and when the laser is active, I have it set to be a nice bright magenta.

I so appreciate having a visual indicator, especially for cleaning passes that sometimes barely show at all (or any completely invisible off-nominal out-of-focus lasering). I also made sure I built the enclosure and installed the door interlock so that it functions well before there are any clear gaps.