Hello all.

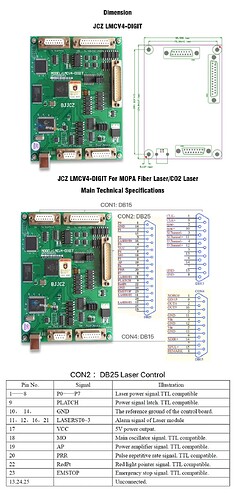

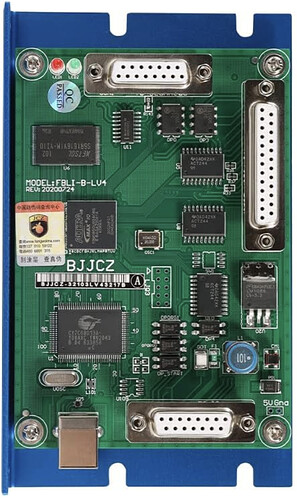

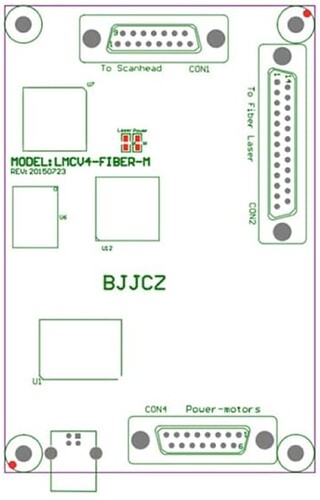

I am planning to buy a laser engraver with an enclosure. It uses the LCZ-LMCV4 control board. Does anyone have any personal experience with this laser or enclosure, or have a recommendation for a better machine? This will be used in a production environment, sometimes with the larger 300x300 engraving area, so I wanted to get a high wattage machine for fast cycle times. I would appreciate any tips/feedback on this setup.

https://www.amazon.com/Marking-Machine-Engraver-Marker-300×300mm/dp/B086GDLHMC/

https://www.amazon.com/Cloudray-Protective-Compatible-800mm-Lift/dp/B09MZ8JDX2

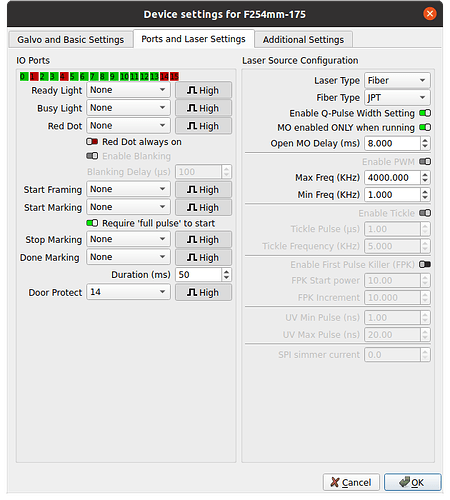

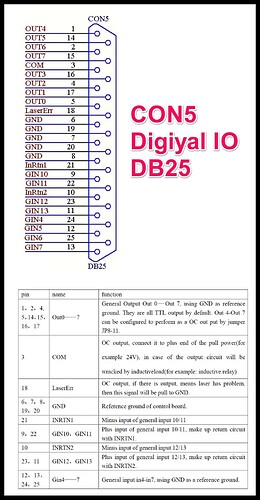

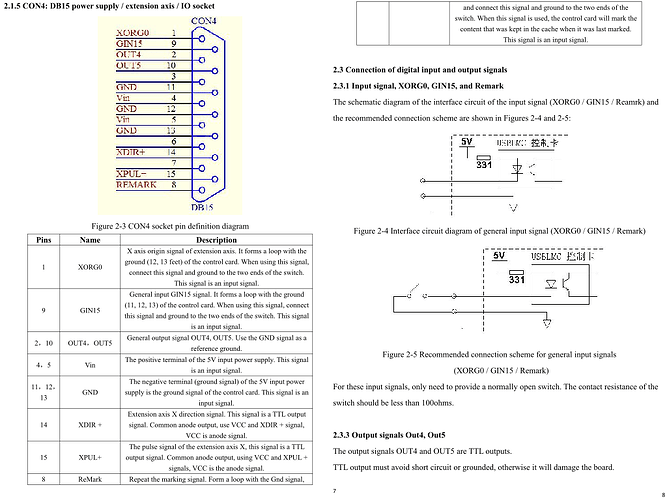

I would like to add a simple door interlock safety switch. Could anyone please advise how this will work with Lightburn? I’ve found that I can use pin 15 for the “door protect” setting in lightburn, but I can’t find any information online about how to wire this pin up to the control board.

Further, I can’t find any information about how this will work exactly. Will opening the door while the laser is on just disable the laser and continue engraving? Or will it act like an E-stop? Will I be able to use the tracer preview function while the door is open? I haven’t been able to find any documentation regarding this function.

Thanks,