Oops, it’s not that easy. If it was the X axis it would be very easy to fix. I think you need to peel off your entire rail system. I hope there are others here in the forum who have a better suggestion but it will surprise me.

I have peeled my frame out once because I have shortened the extraction nozzle and replaced the bed itself with something homemade. It’s not that bad either, but when the machine is new you would rather engrave and cut with the laser than rebuild the machine. (… it will probably come anyway - but later

I am at the point of a rebuild. I found an access hole in the back of the machine on the left and the right to adjust the belt tension, there is just a screw to tension but I guess you know that already if you have pulled the machine apart  .

.

I now cannot get the y axis to move forwards yet it goes home fine. When you jog the head forwards on the y axis it just vibrates, if I “assist” by pushing lightly on the gantry then it moves forwards to a point.

It does return home fine though. I am at a complete loss.

I have found a good thread at awesometech that could possibly help you.

https://awesome.tech/k40-forum/topic/mini-gerbil-fine-tuning/

But first you need to examine all the mechanics. When turned off, can you move your laser head without noticeable resistance in all directions?

If that’s happening, check the speed you’re asking it to jog. You might have the motor current value for the Y axis set too low, or the acceleration or speed set too high. If the motor just squeals, but works with a nudge, it’s skipping.

Oz, that sounds like what could be happening but I would not have a clue where to start to change it. It does only take a nudge to start it.

Jogging at 200mm/sec, works great on x axis but not on y.

Yes I can. There was a little resistance but I managed to get around that and it is free now. I’ll take a look at the link although I fear I may have already looked at that one.

Thanks again.

Go to Edit > Machine Settings and look at the settings for Y acceleration and Y maximum speed (in the “vendor settings” section in the bottom - you’ll need to unroll it).

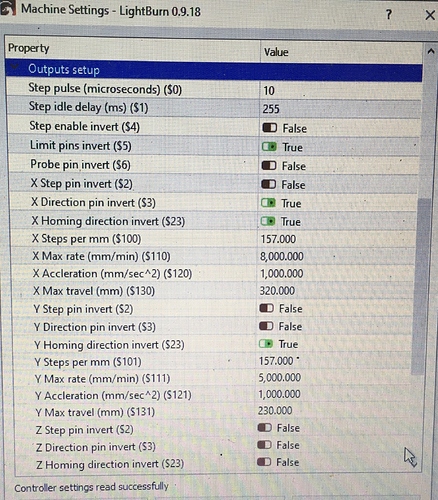

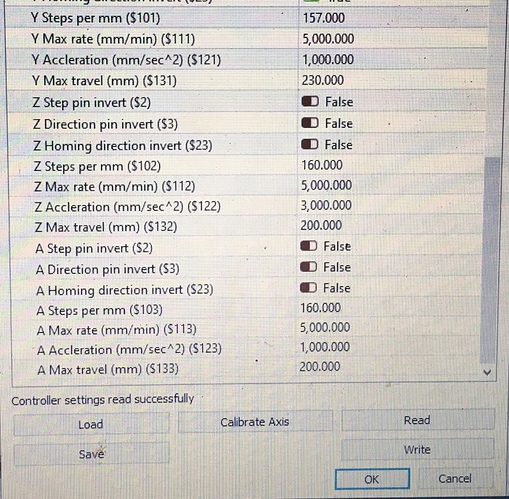

Settings are attached. I think I have already reduced max Y acceleration but please review all settings and let me know what will help.

Just to be on the safe side, I have a K40 with Mini-Gerbil, 1.1f.

The biggest difference is your or my machine orientation. My X ( 130) is 230 and Y ( 131) is 320.

Differences in a few other things are:

110 = 11000

111 = 6000

120 = 5000

121 = 3000

$ 123 = 3000

sorry formatting also missing some $ characters, it’s probably lost in Google Translation

Thanks Bernd,

I have taken a quick video of what it does and doesn’t do but this site won’t let me upload it. Basically I can get the x and y axis moving on their own but as soon as I run a programme, the y axis seems to stick?

Could it be a problem with the y axis motor?

you could easily test it if you just swap the plugs but turn autohoming off first.

Videos are too big for the forum here, when I make them, I use Youtube and make a link there.

How about homing? my homing is top-left and what about the swapped x and y?

Try lowering the Y Acceleration more.

You can upload video to YouTube, Vimeo, DropBox, etc and link it here, but we don’t have the storage space for user videos.

Your two sides are out of whack - they will be one tooth out on the belt. That’s jamming your Y axis.

That so7nds like a great diagnosis. I will certainly check this out. Thank you sir

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.