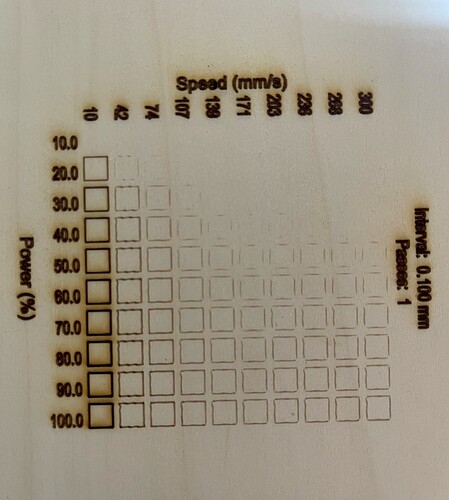

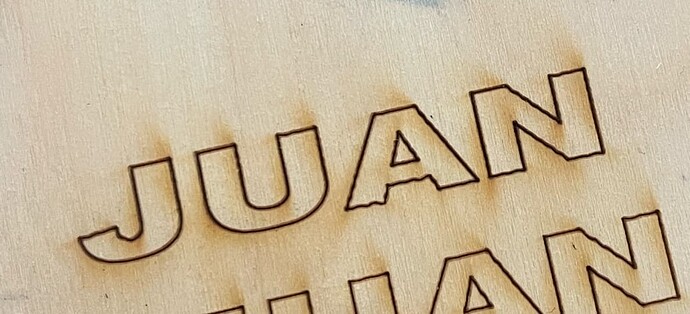

“I have recently upgraded my K40 laser to a larger bed size. Everything seems fine with the modification, except that I can no longer use high speeds after the upgrade. I’m still using the same mechanisms, such as the stepper motor, belt, and settings, but I’m facing a problem with the engraving process. When I attempt to engrave text or shapes at a fast pace, the output comes out wavy and distorted. Currently, I can’t go faster than 10mm/s, whereas, with the old version, I remember being able to achieve higher speeds. Can anyone help me with this issue?”

This has all the signs of a mechanical issue… Belts, pulleys, lens, tube or something is not secure.

There is also resonance that occurs at certain speeds that can aggravate/confuse the issue. It also goes along with enlarging the work area…

I assume you’re using a grbl controller? Not that it matters here…

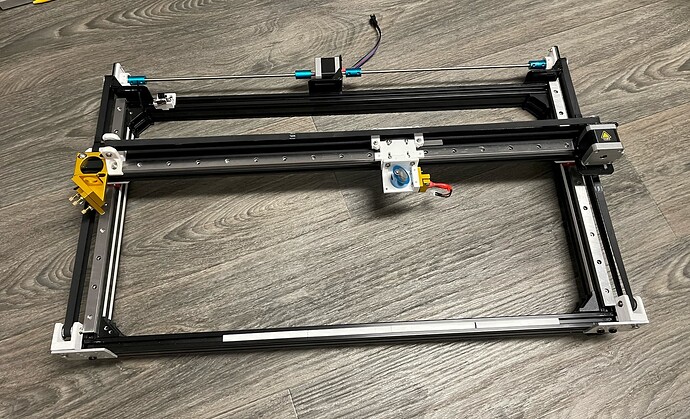

Isn’t that drag chain in the operators area and in the way?

![]()

Im using smoothieware controller i think, i have make sure everything is tight i replace the belt to the 2.32 belt the one that comes with the original but nothing has charge i will check all pulleys and see i have been in this project for two month has been hard to understand all this and create 3d prints part but i will get it !!!

The best detail you can be with the mechanical… I’ve seen this before and it usually resolves to a lose belt, head, mirror or something that moves a tiny bit.

Don’t work with it when you are tired and frustrated… it will only end in grief…

We’re here if you have questions…

Good luck

![]()

One of the consequences of making a beam longer, without changing its shape or cross-section, is that it becomes more flexible. IIRC, the deflection varies as the fourth power of the length, so doubling the gantry beam length increased its deflection by a factor of 16.

After you’ve secured all the mechanical bits, you may be looking at how much the forces applied to that longer gantry beam bend it.

Without changing anything else, the only way to reduce the deflection is to reduce the force applied to the beam, which (as you’ve found) requires lowering the acceleration and speed of the laser motions.

thank you i found a problem one of the bearing has problem from factory isn’t rotary and the other problem is the X axis is so heaving so the stepper motor need mor amps to move the whole piece, so. im making some adjustment i think will be good i will let you know about the result

I have made some adjustments and frame corrections, I have mounted the motor in the middle of the frame, I have redesigned the gantry plate, and fix the lens gantry plate too, now machine is running smooth I will try high speed and see results

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.