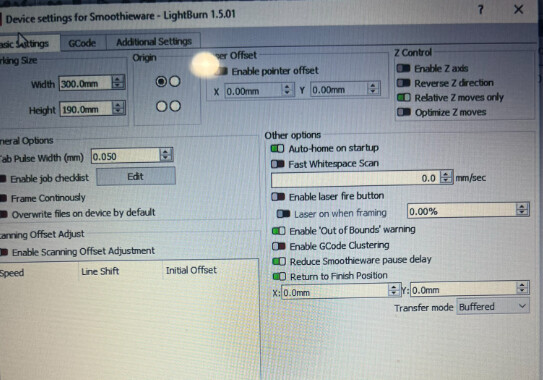

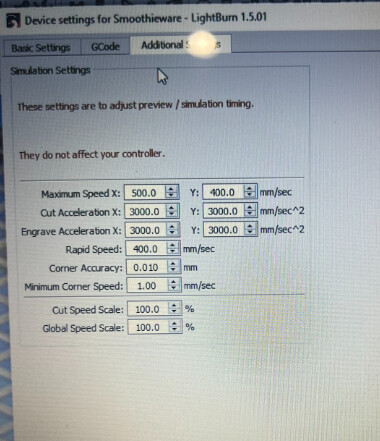

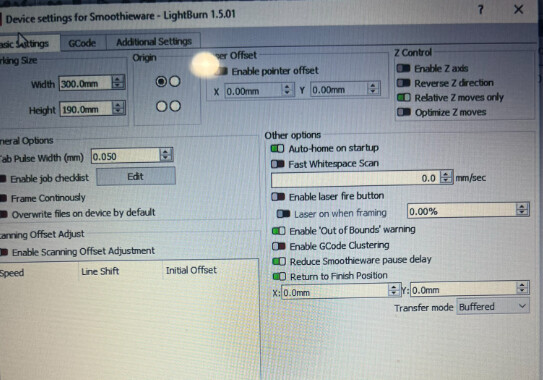

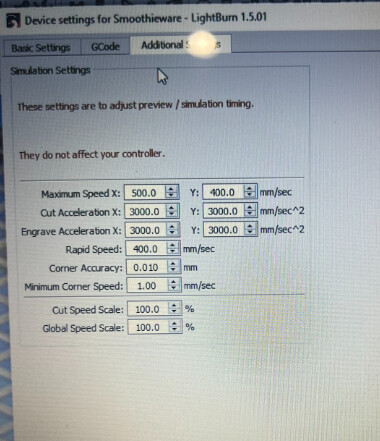

I know this topic has been covered and i still cant get it right. All speeds when not engraving move too fast and spin the part in the roller. Below are screenshots of my settings. Can someone highlight the settings i need to adjust?

I know this topic has been covered and i still cant get it right. All speeds when not engraving move too fast and spin the part in the roller. Below are screenshots of my settings. Can someone highlight the settings i need to adjust?

Are you referring to the movements the machine makes between burn?

Do you mean the “Idle Speed” parameter?

I assume a wheel or roller rotary. These are inclined to do this as there is no way to ensure traction with the object and it’s driving wheel or roller…

I have both a wheel rotary (PiBurn 3) and a D80 chuck rotary.

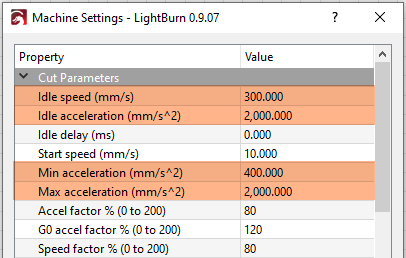

When I use the wheel rotary I have a file that changes the controllers jump off speed and acceleration values that prevent this from occurring. You only need to do this on the axes that is causing the issue, generally the Y axes.

This file is manipulated by Edit → Machine Settings gui. The jump off speed may not be available with grbl.

I also convert vector to scan graphics to keep the rotary from changing directions which exacerbates the issue.

Make sense?

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.